In essence, PTFE-encapsulated O-rings deliver an exceptional combination of chemical inertness, wide temperature tolerance, and low-friction performance. They are engineered to provide the sealing capabilities of a traditional elastomer O-ring while being protected by a seamless jacket of Polytetrafluoroethylene (PTFE), making them ideal for aggressive or high-purity sealing environments.

The core advantage is not just the properties of PTFE, but how it is combined with a traditional elastomer core. This dual-material design provides the chemical resilience of PTFE with the elasticity and memory required for a reliable, long-lasting seal, solving problems where neither material could succeed alone.

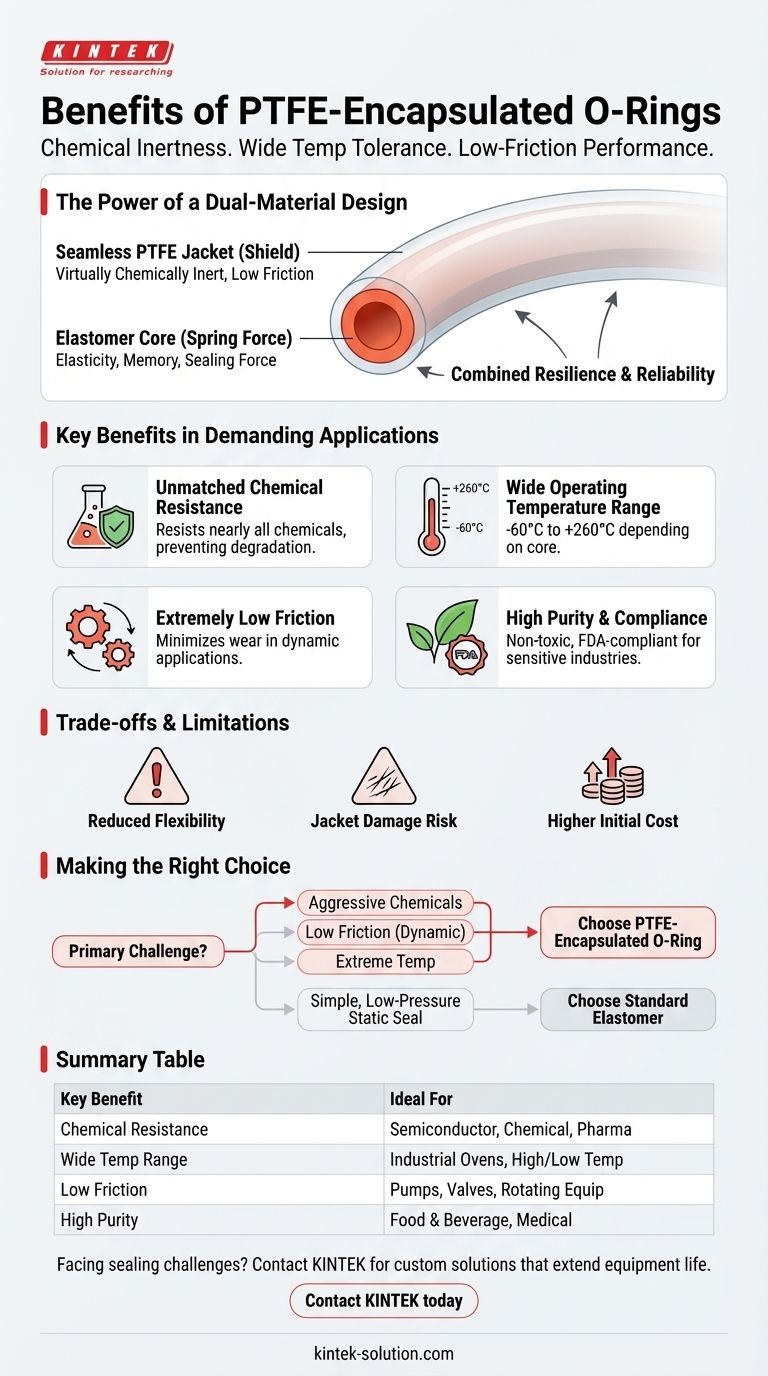

The Power of a Dual-Material Design

A standard O-ring made from a single elastomer (like Viton or Silicone) can fail when exposed to aggressive chemicals or extreme temperatures. A solid PTFE O-ring has the resistance but lacks the elasticity needed for a reliable seal. The encapsulated design solves this fundamental conflict.

The PTFE Shell: Your Shield Against Harsh Environments

The outer layer is a thin, seamless jacket of PTFE. This shell is what comes into contact with the operating environment.

Because PTFE is virtually chemically inert, the O-ring is protected from a vast range of corrosive fluids, solvents, and gases that would degrade other materials.

This shell also gives the O-ring an extremely low coefficient of friction and non-stick properties, making it ideal for dynamic applications where parts slide against the seal.

The Elastomer Core: Providing Essential Sealing Force

Inside the PTFE shell is a core made of a standard elastomer, typically Silicone or FKM (Viton).

This core provides the elasticity and memory that the rigid PTFE shell lacks. When compressed, the core pushes back against the sealing surfaces, creating the reliable, long-term force needed to prevent leaks.

This "live" energy from the core allows the seal to adapt to minor imperfections and maintain its effectiveness over time, resisting the compression set that can cause leaks in solid seals.

Key Benefits in Demanding Applications

The unique construction of PTFE-encapsulated O-rings translates directly into superior performance in specific, challenging scenarios.

Unmatched Chemical Resistance

The PTFE jacket is resistant to nearly all industrial chemicals and solvents. This prevents the swelling, hardening, or degradation that causes premature failure in standard elastomer seals.

Wide Operating Temperature Range

The choice of elastomer core combined with the PTFE shell allows for a very broad service temperature range.

Depending on the core material, these seals can operate reliably from as low as -60°C up to +260°C (approx. -75°F to +500°F).

Extremely Low Friction for Dynamic Seals

The "slippery" surface of the PTFE shell minimizes friction and stick-slip behavior in reciprocating or rotating applications.

This reduces wear on both the seal and the equipment, lowers operational energy requirements, and ensures smoother performance.

Compliance for Sensitive Industries

PTFE is inherently non-toxic and can be compliant with FDA regulations for food contact.

This makes encapsulated O-rings an excellent choice for sealing applications in the food, beverage, and pharmaceutical industries where purity is critical.

Understanding the Trade-offs and Limitations

While powerful, PTFE-encapsulated O-rings are not a universal solution. Their unique construction introduces specific limitations that must be considered for successful implementation.

Reduced Flexibility

The PTFE jacket is significantly stiffer than a standard elastomer. This makes the O-rings less flexible, which can make installation more difficult, especially in small grooves or tight spaces.

Potential for Jacket Damage

The PTFE shell, while durable, can be scratched or damaged during installation if not handled carefully. Any breach in the jacket exposes the vulnerable inner core, defeating the purpose of the seal.

Higher Initial Cost

The multi-step manufacturing process makes encapsulated O-rings more expensive than standard single-material elastomer O-rings. However, this higher upfront cost is often justified by reduced downtime and longer service life in aggressive environments.

Making the Right Choice for Your Application

Selecting an encapsulated O-ring depends entirely on whether your primary challenge is chemical attack, temperature, or friction.

- If your primary focus is aggressive chemical compatibility: This is the ideal seal. The inert PTFE shell protects the core from nearly any media, preventing seal degradation and extending equipment life.

- If your primary focus is low-friction dynamic sealing: The PTFE surface provides excellent lubricity for applications with moving parts, reducing wear and stick-slip issues.

- If your primary focus is extreme temperature range: An encapsulated O-ring with the correct core material offers a robust solution for both high and low-temperature sealing where elastomers alone would fail.

- If your primary focus is a simple, low-pressure static seal with standard fluids: A standard elastomer O-ring is likely a more flexible and cost-effective solution.

Ultimately, choosing a PTFE-encapsulated O-ring is a strategic decision to solve specific environmental challenges that commodity seals cannot withstand.

Summary Table:

| Key Benefit | Description | Ideal For |

|---|---|---|

| Chemical Resistance | Inert PTFE shell resists corrosive fluids, solvents, and gases. | Semiconductor, chemical processing, pharmaceutical |

| Wide Temperature Range | Operates from -60°C to +260°C, depending on elastomer core. | High/low-temperature processes, industrial ovens |

| Low Friction | PTFE surface minimizes friction and wear in dynamic applications. | Reciprocating pumps, valves, rotating equipment |

| High Purity / Compliance | Non-toxic, FDA-compliant material for sensitive environments. | Food & beverage, medical, laboratory equipment |

Facing sealing challenges in aggressive environments? PTFE-encapsulated O-rings from KINTEK offer a reliable solution. Our expertise in manufacturing high-performance PTFE components—including custom seals, liners, and labware—ensures precision and durability for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, we deliver the right seal for your application.

Contact KINTEK today to discuss your specific requirements and get a custom solution that extends equipment life and reduces downtime.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support