The primary benefits of Modified Polytetrafluoroethylene (PTFE) with a carbon-graphite fill are its balanced performance characteristics, making it ideal for demanding sealing applications. This material combines low friction, a very wide operating temperature range (-300°F to 500°F), and broad chemical resistance with good wear properties that are specifically designed to be gentle on mating metal surfaces.

The core advantage of this material is its strategic blend of properties. The "Modified PTFE" base provides superior resistance to deformation under load, while the "Carbon-Graphite" filler adds wear resistance and self-lubrication without damaging the expensive components it seals against.

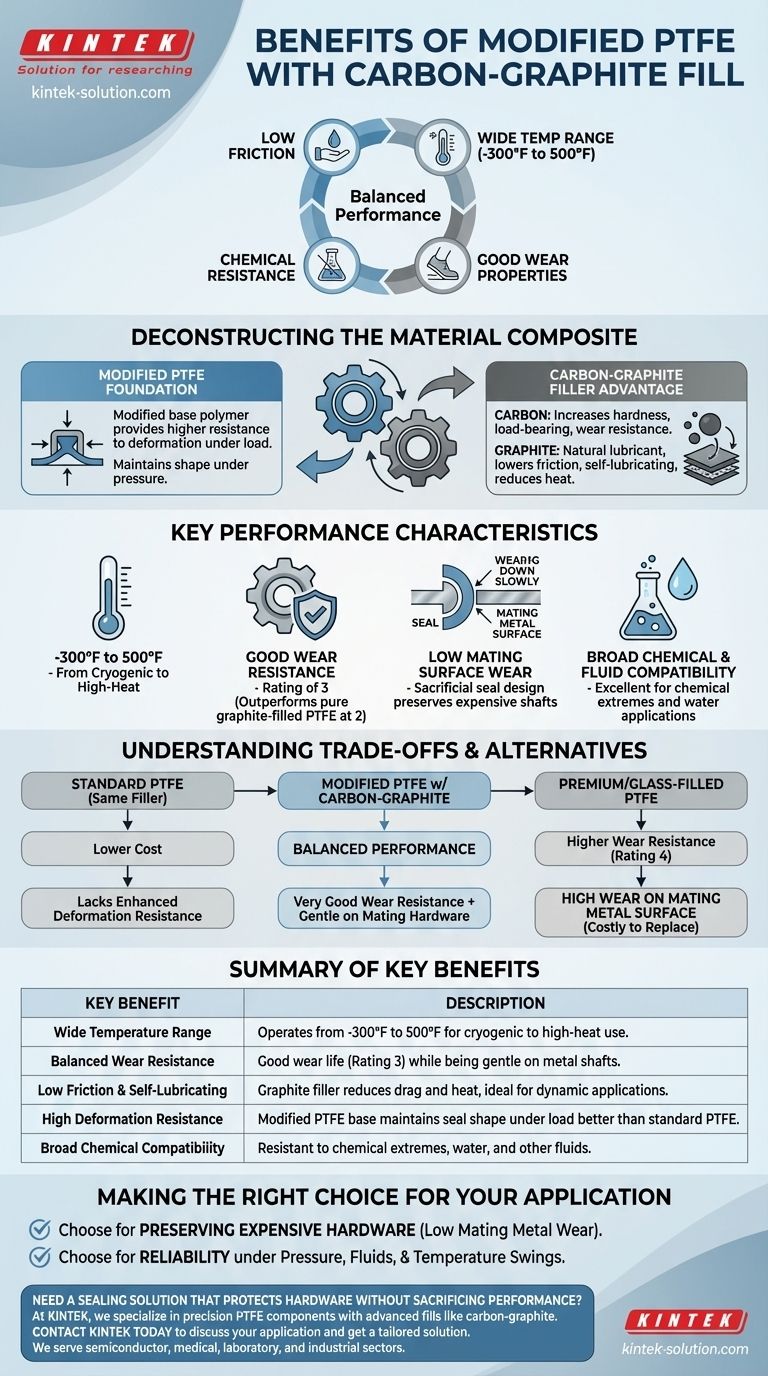

Deconstructing the Material Composite

To understand the benefits, it's essential to analyze the two key components that make up this material.

The "Modified PTFE" Foundation

The base polymer is not standard PTFE, but a modified version. This modification provides a significant structural advantage.

Its primary benefit is a higher resistance to deformation compared to standard, unfilled PTFE. This is critical for seals and bearings that must maintain their shape under pressure and over time to prevent leaks.

The "Carbon-Graphite" Filler Advantage

Adding fillers is how a base polymer like PTFE is tailored for specific performance needs.

Carbon is added to increase hardness, load-bearing capability, and overall wear resistance.

Graphite is a natural lubricant, which dramatically lowers the coefficient of friction. This self-lubricating property is essential for reducing drag and heat buildup in dynamic applications. This blend is particularly effective in humid conditions or aqueous fluid media.

Key Performance Characteristics

The combination of the modified base and the specific filler results in a set of well-rounded performance traits.

Wide Operating Temperature Range

The material is rated for service from -300°F to 500°F. This makes it suitable for applications ranging from cryogenic processes to high-heat industrial equipment.

Good Wear Resistance

With a typical wear resistance rating of 3 (on the provided scale), it offers a significant improvement over materials with less robust fillers, like pure graphite-filled PTFE (rated at 2).

Low Mating Surface Wear

This is arguably one of its most critical benefits. This material is designed to be sacrificial, meaning the seal itself wears down slowly while preserving the integrity of the more expensive metal shaft or bore it runs against.

Broad Chemical and Fluid Compatibility

Building on PTFE's inherent chemical inertness, this material is specified for use in applications with chemical extremes. The carbon-graphite filler also makes it an excellent choice for use in water and other fluid applications.

Understanding the Trade-offs and Alternatives

No material is perfect for every situation. Choosing this composite involves understanding its place among other filled-PTFE options.

Standard PTFE vs. Modified PTFE

The primary trade-off is performance versus cost. While standard PTFE with the same filler offers similar temperature and wear ratings, it lacks the enhanced deformation resistance of the modified version. If dimensional stability under load is your top priority, the modified base is superior.

The Lure of Higher Wear Resistance

Other fillers, such as glass or premium organic compounds, can achieve a higher wear resistance rating (4). However, this often comes at a steep cost.

Glass-filled PTFE, for example, results in high wear on the mating metal surface. Similarly, some premium fillers can cause medium metal wear. This creates a critical engineering choice: is it more cost-effective to replace a seal more often or to resurface or replace a costly metal shaft?

Balanced Performance is the Goal

The Modified PTFE with Carbon-Graphite blend represents a deliberate engineering compromise. It offers very good wear resistance without introducing the aggressive, abrasive wear on hardware that other high-performance fillers can cause.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary operational goal.

- If your primary focus is preserving expensive hardware: This material is an excellent choice due to its low mating metal wear characteristics.

- If your primary focus is maximum seal lifespan in extreme wear conditions: You might consider a premium-filled PTFE, but you must accept the trade-off of potentially higher wear on your mating surfaces.

- If your primary focus is reliability in applications with pressure, fluids, and temperature swings: The combination of deformation resistance, chemical compatibility, and low friction makes this a robust, well-rounded solution.

Ultimately, choosing Modified PTFE with a carbon-graphite fill is a decision for balanced performance where protecting system hardware is as important as the longevity of the seal itself.

Summary Table:

| Key Benefit | Description |

|---|---|

| Wide Temperature Range | Operates from -300°F to 500°F for cryogenic to high-heat use. |

| Balanced Wear Resistance | Good wear life (rating of 3) while being gentle on metal shafts. |

| Low Friction & Self-Lubricating | Graphite filler reduces drag and heat, ideal for dynamic applications. |

| High Deformation Resistance | Modified PTFE base maintains seal shape under load better than standard PTFE. |

| Broad Chemical Compatibility | Resistant to chemical extremes, water, and other fluids. |

Need a sealing solution that protects your hardware without sacrificing performance?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom seals and liners with advanced fills like carbon-graphite. Our expertise ensures you get a component that delivers the perfect balance of long service life and minimal wear on your expensive mating surfaces.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your application and get a solution tailored to your exact needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech