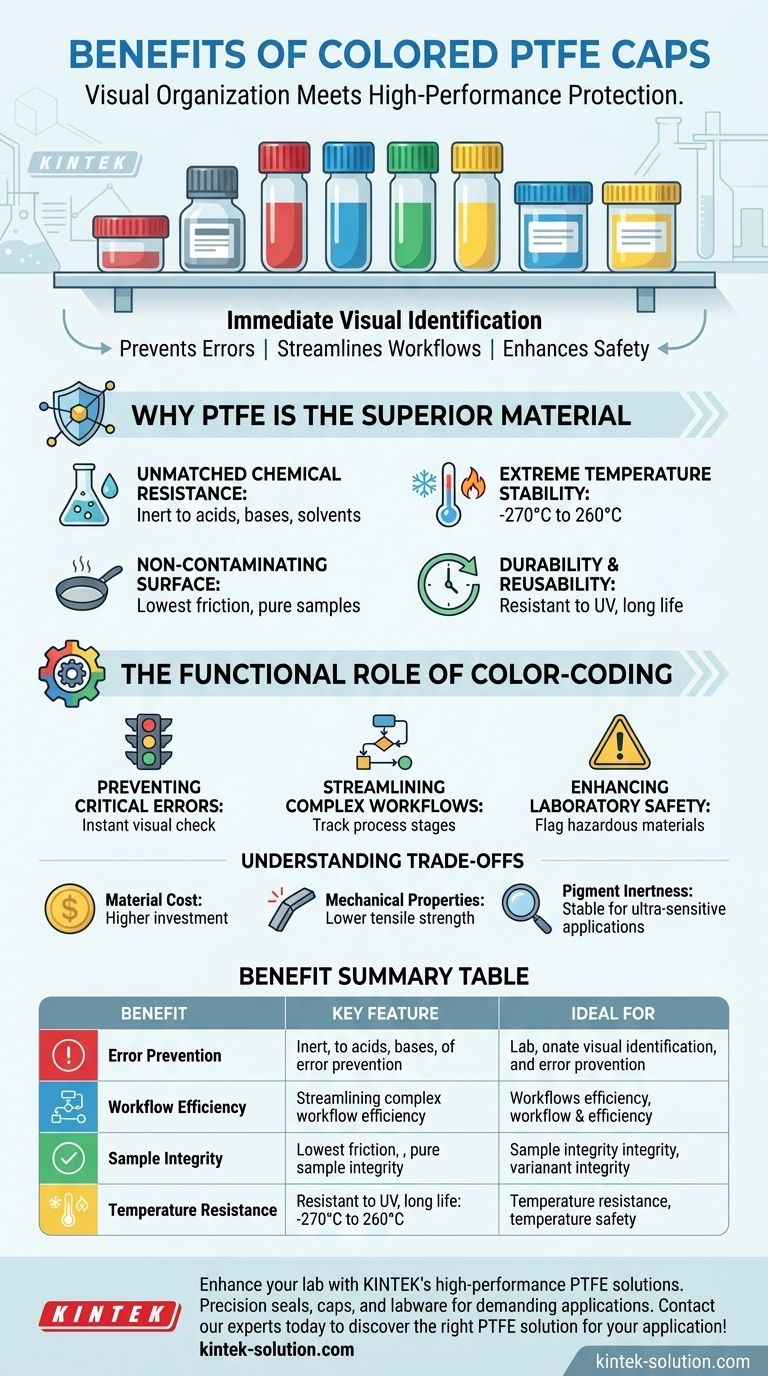

The primary benefit of colored PTFE caps is straightforward: immediate visual identification. The color serves as a simple, effective coding system for organizing samples, reagents, or different stages of a process in a laboratory or industrial setting. This visual cue helps prevent cross-contamination, reduce errors, and streamline complex workflows.

While the color provides immense organizational value, the true benefit lies in the underlying material. PTFE is chosen for caps because its exceptional chemical inertness, temperature resistance, and non-stick properties ensure the cap will not react with, contaminate, or adhere to the substance it contains.

Why PTFE is the Material of Choice

Before understanding the value of color, it's essential to understand why PTFE (Polytetrafluoroethylene) is a superior material for demanding applications. Its unique molecular structure, composed of strong carbon-fluorine bonds, gives it a set of properties that are ideal for sealing and protecting sensitive contents.

Unmatched Chemical Resistance

PTFE is famously inert and non-reactive with nearly all acids, bases, and solvents. This makes it an essential material for applications in chemistry and pharmaceuticals where container integrity is non-negotiable.

Extreme Temperature Stability

The material demonstrates remarkable thermal stability, capable of withstanding continuous working temperatures from cryogenic lows of -270°C up to 260°C (-454°F to 500°F). This allows PTFE caps to be used for a vast range of heating, cooling, and storage protocols where other polymers would fail.

Non-Contaminating Surface

PTFE has one of the lowest coefficients of friction of any solid material, giving it exceptional non-stick properties. This ensures that the contents do not adhere to the cap, preserving the purity and full volume of the sample.

Durability and Reusability

The material is highly resistant to degradation from UV rays, oxidation, and moisture. This inherent durability means PTFE caps have a long service life and can be reliably cleaned and reused, providing excellent long-term value.

The Functional Role of Color-Coding

Adding color to a high-performance PTFE cap elevates it from a simple seal to an active organizational tool. This system leverages the material's performance while adding a layer of safety and efficiency.

Preventing Critical Errors

In a busy lab, using distinct colors—for example, red for acids, blue for bases, green for standards—provides an instant visual check. This simple system can prevent dangerous chemical mixtures and costly sample contamination.

Streamlining Complex Workflows

For multi-step experiments or production processes, colored caps can signify different stages. A workflow might move from a green-capped vial (raw sample) to a yellow-capped one (in-process) to a blue-capped one (final product), making the status of each container immediately clear.

Enhancing Laboratory Safety

Colors can be used to quickly identify hazardous materials or samples requiring special handling protocols. This visual flagging system enhances situational awareness and reinforces safety compliance for all personnel.

Understanding the Trade-offs

While PTFE is an exceptional material, no single solution is perfect for every scenario. An objective assessment requires acknowledging its limitations.

Material Cost

PTFE is a high-performance polymer, and its cost is generally higher than common plastics like polypropylene or polyethylene. The investment is justified by its superior chemical and thermal resistance, but it may be unnecessary for less demanding applications.

Mechanical Properties

PTFE is a relatively soft material with lower tensile strength compared to other engineering plastics. This is rarely a concern for a cap or seal, but it means PTFE is not suitable for high-load, structural components.

Pigment Inertness

For ultra-sensitive applications, it is critical to ensure the pigment used to color the PTFE is as inert as the polymer itself. Reputable manufacturers use stable, encapsulated pigments, but this is a valid consideration for trace analysis or highly reactive chemistry.

Making the Right Choice for Your Application

Choosing the right cap requires matching the material's properties and features to your specific operational needs.

- If your primary focus is sample integrity with aggressive chemicals: Prioritize standard PTFE for its unparalleled chemical inertness; the color is a secondary organizational benefit.

- If your primary focus is managing multiple, distinct workflows: Implement a strict color-coding system with PTFE caps to reduce errors and improve overall efficiency.

- If your primary focus is high-temperature or cryogenic storage: Confirm the cap's specified temperature range, as PTFE excels in these conditions where most other plastics would become brittle or melt.

Ultimately, a colored PTFE cap combines the robust, non-reactive performance of a superior polymer with the simple, powerful advantage of visual organization.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Error Prevention | Instant visual identification of contents | Managing acids, bases, and hazardous materials |

| Workflow Efficiency | Color-coded tracking of process stages | Multi-step experiments and production lines |

| Sample Integrity | PTFE's chemical inertness and non-stick surface | Protecting sensitive samples and reagents |

| Temperature Resistance | Stable from -270°C to 260°C | High-temperature and cryogenic applications |

Ready to enhance your lab's safety and organization with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE seals, caps, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a reliable standard product or a custom-fabricated solution—from prototypes to high-volume orders—we ensure the highest quality and material integrity to protect your processes.

Contact our experts today to discuss your specific requirements and discover the right PTFE solution for your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance