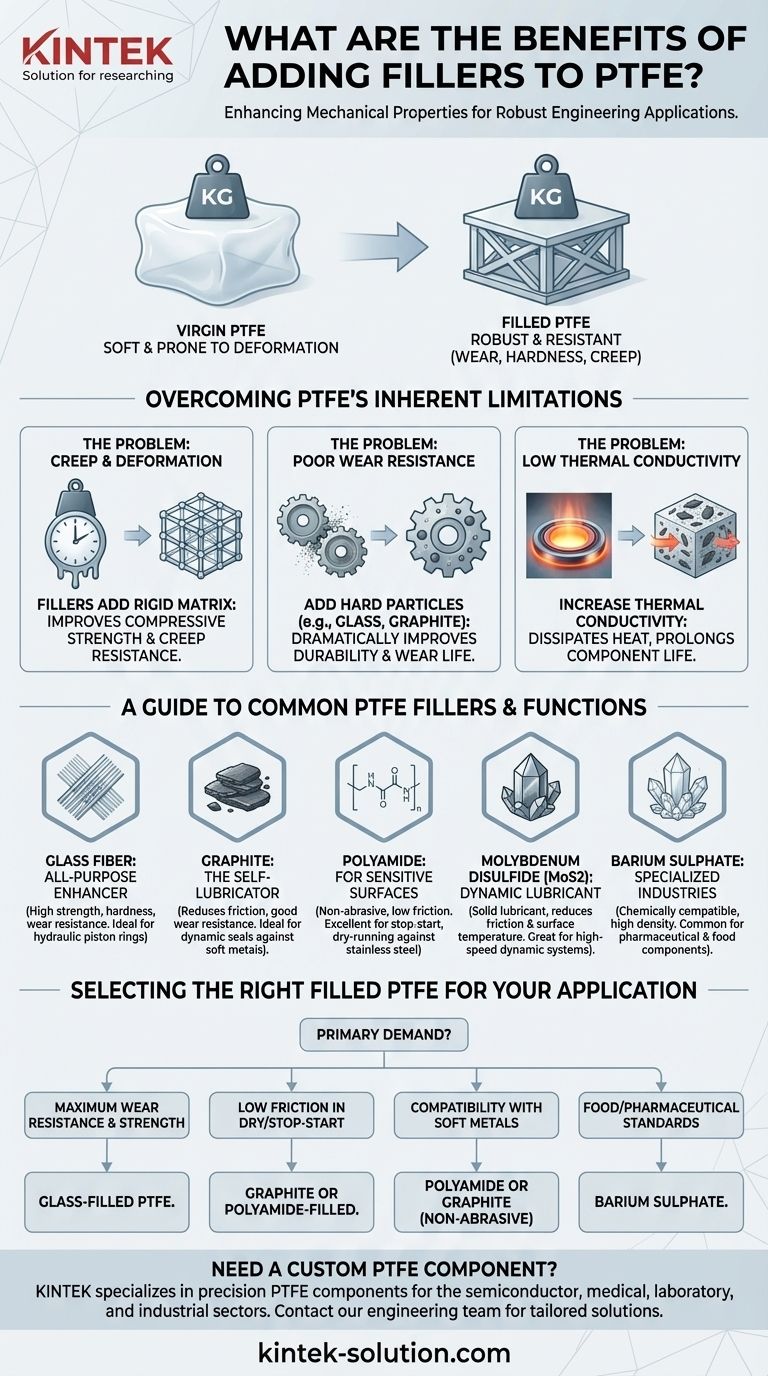

The primary benefit of adding fillers to PTFE is to significantly enhance its mechanical properties. Virgin Polytetrafluoroethylene (PTFE) is soft and prone to deforming under load, but adding fillers like glass, graphite, or polyamide transforms it into a robust engineering material with superior wear resistance, hardness, and resistance to creep.

While virgin PTFE is valued for its extreme chemical inertness and low friction, it lacks the mechanical strength for demanding applications. Fillers are the key to overcoming these limitations, allowing engineers to tailor PTFE's properties for specific high-stress environments like seals, bearings, and piston rings.

Overcoming PTFE's Inherent Limitations

Virgin PTFE is an excellent material in many respects, but its physical properties create significant design constraints. Fillers directly address these core weaknesses.

The Problem of Creep and Deformation

Pure PTFE has a tendency to "creep," or slowly deform, when subjected to a sustained load, especially at elevated temperatures. This makes it unsuitable for high-pressure seals or structural components.

Fillers add a rigid matrix within the PTFE, providing structural reinforcement. This drastically improves compressive strength and creep resistance, allowing the material to maintain its shape under heavy, constant loads.

Poor Wear Resistance

The low friction of PTFE does not automatically translate to high wear resistance. The material is soft and can abrade quickly in dynamic applications.

Adding hard particles like glass fibers or graphite dramatically improves the material's durability and wear life. This makes filled PTFE a superior choice for components like piston rings and bearings that experience continuous movement.

Low Thermal Conductivity

Friction generates heat. Because virgin PTFE is a poor thermal conductor, this heat can build up at the contact surface, potentially leading to premature failure.

Fillers such as graphite can increase thermal conductivity. This allows the material to dissipate frictional heat more effectively, enhancing durability and prolonging the life of components like dynamic seals.

A Guide to Common PTFE Fillers and Their Functions

The choice of filler is critical, as each one imparts a unique set of properties. Selecting the right filler is essential for optimizing performance for a specific application.

Glass Fiber: The All-Purpose Enhancer

Glass is the most widely used filler in PTFE. It provides an excellent all-around improvement in compressive strength, hardness, and wear resistance.

It is highly effective in applications like hydraulic piston rings. However, it can be abrasive to softer mating surfaces like aluminum or brass.

Graphite: The Self-Lubricator

Graphite provides self-lubricating properties, which helps to reduce the coefficient of friction. It is often combined with other fillers like glass or carbon.

Its flaky form offers good wear resistance and is ideal for applications requiring low friction and slow corrosion, particularly with softer metals.

Polyamide: For Sensitive Mating Surfaces

Polyamide offers a low friction coefficient and is non-abrasive, making it an excellent choice for use against stainless steel, plastic, brass, and aluminum surfaces.

As a synthetic polymer, it is well-suited for stop-start scenarios and applications that are dry-running or non-lubricated.

Molybdenum Disulfide (MoS2): The Dynamic Lubricant

Similar to graphite, MoS2 acts as a solid lubricant, reducing friction in dynamic applications. It is particularly effective at reducing the interface surface temperature of seals.

This filler is often used to enhance durability and prolong seal life in high-speed or high-pressure moving systems.

Barium Sulphate: For Specialized Industries

Barium sulphate is a high-density filler used where chemical compatibility and compliance are critical.

Its properties make it a common choice for applications in the pharmaceutical and food industries, especially for components used in steel or stainless steel pipelines.

Understanding the Trade-offs

While fillers provide significant benefits, they also introduce trade-offs that must be considered during material selection.

Compromised Chemical Resistance

Virgin PTFE is almost universally chemically inert. However, some fillers, particularly glass, can be attacked by strong acids or alkalis. This slightly reduces the material's overall chemical compatibility.

Potential for Increased Abrasion

Hard fillers like glass greatly improve the wear resistance of the PTFE part itself, but they can be abrasive to the mating surface. If the component runs against a soft material like aluminum, a non-abrasive filler like graphite or polyamide is a better choice.

Changes to Frictional Properties

While some fillers like graphite reduce friction, others can increase it compared to virgin PTFE. The final coefficient of friction depends on the specific filler, its percentage, and the operating conditions.

Selecting the Right Filled PTFE for Your Application

The ideal material is always a function of the specific problem you are trying to solve. Use the application's primary demand to guide your choice.

- If your primary focus is maximum wear resistance and compressive strength: Glass-filled PTFE is often the most effective and common choice.

- If your primary focus is low friction in dry or start-stop applications: A graphite or polyamide-filled compound will likely deliver the best performance.

- If your primary focus is compatibility with soft metal surfaces (e.g., aluminum): Choose a non-abrasive filler like polyamide or graphite to prevent damage.

- If your primary focus is compliance with food or pharmaceutical standards: Barium sulphate is a specifically designed and suitable choice.

By understanding the function of each filler, you can specify a material that precisely meets the mechanical and environmental demands of your design.

Summary Table:

| Filler Type | Key Benefits | Ideal Applications |

|---|---|---|

| Glass Fiber | High compressive strength, hardness, wear resistance | Hydraulic piston rings, bearings |

| Graphite | Self-lubricating, low friction, good wear resistance | Dynamic seals, components against soft metals |

| Polyamide | Non-abrasive, low friction, suitable for sensitive surfaces | Stop-start applications, dry-running systems |

| Molybdenum Disulfide | Solid lubricant, reduces friction and surface temperature | High-speed seals, dynamic systems |

| Barium Sulphate | Chemically compatible, compliant with food/pharma standards | Pharmaceutical, food industry components |

Need a custom PTFE component that perfectly balances wear resistance, strength, and chemical compatibility?

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in filler selection and custom fabrication ensures your parts meet the exact mechanical and environmental demands of your application, whether you need prototypes or high-volume production.

Contact our engineering team today to discuss your specific requirements and get a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support