PTFE envelope gaskets are available in a vast range of sizes to fit standard industrial piping, from as small as 12mm up to DN2000. These sizes are defined by major international standards like ASME, EN, and DIN to ensure compatibility. Overall gasket thickness typically ranges from 1mm to 10mm, with the critical PTFE envelope itself usually having a thickness of 0.5mm, though custom dimensions are widely available for unique applications.

The key is to understand that a gasket's "size" is not just a single measurement. It's a system defined by the nominal pipe size, the governing flange standard, and the required thickness—all of which must be correctly matched to the application to guarantee a reliable, leak-free seal.

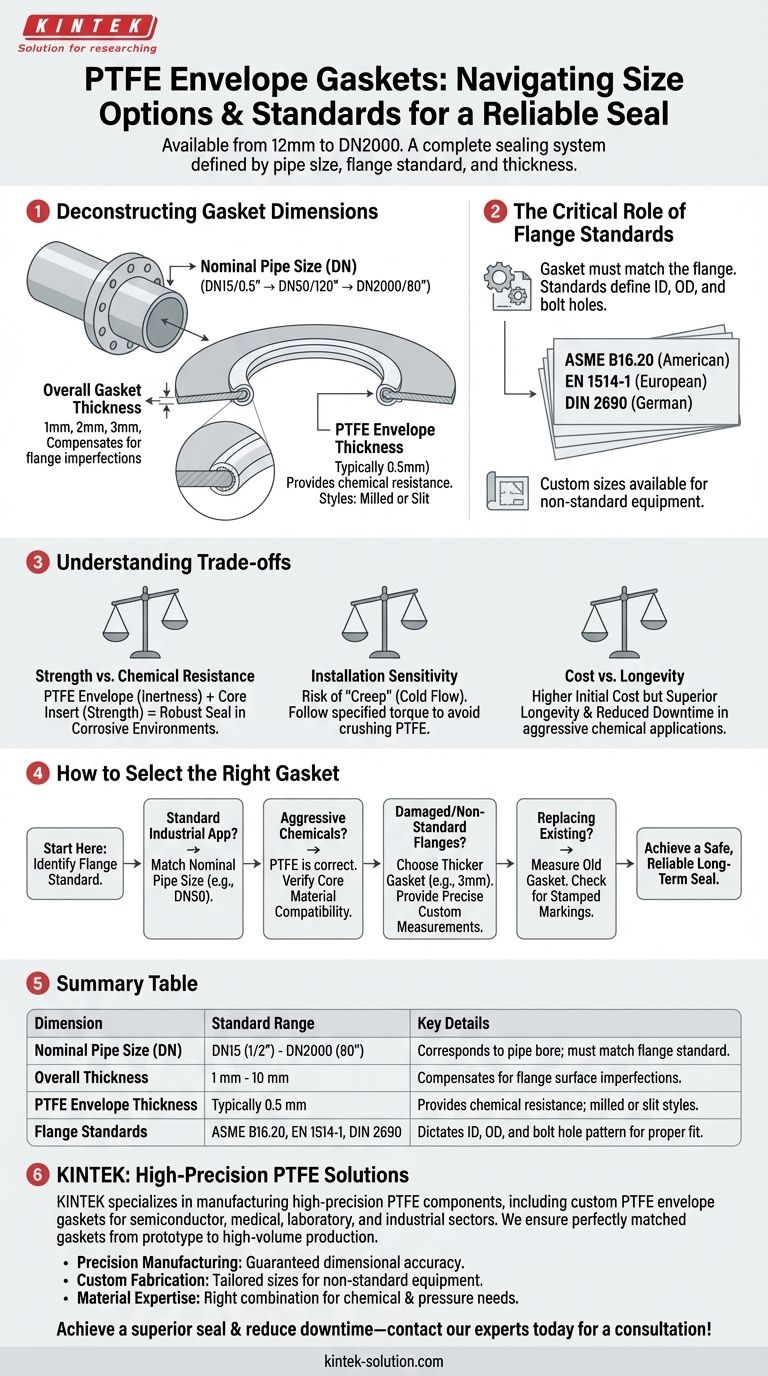

Deconstructing Gasket Dimensions

To select the correct gasket, you must understand the components that define its size and shape. Each dimension serves a specific function in creating a secure seal.

Nominal Pipe Size (DN)

The primary sizing metric is the Nominal Pipe Size, often expressed as DN (Diamètre Nominal) in metric systems or NPS (Nominal Pipe Size) in imperial systems. This corresponds to the pipe's internal bore.

Standard sizes range from DN15 (1/2") to DN2000 (80"), covering the vast majority of industrial piping applications.

Overall Gasket Thickness

The total thickness of the gasket is critical for compensating for any imperfections on the flange surfaces.

Common thicknesses include 1 mm, 2 mm, 3 mm, 4 mm, 5 mm, and 6 mm, with thicker options available up to 10mm or more for custom needs. A thicker gasket can better fill in irregularities on worn or warped flanges.

Envelope Thickness & Type

This refers specifically to the thickness of the PTFE layer that encapsulates the core material, typically around 0.5mm. It is this envelope that provides the gasket's signature chemical resistance.

Envelopes are manufactured in two main styles: milled (machined from a single PTFE cylinder for a seamless face) or slit (cut from a sheet and welded), depending on the size and application requirements.

The Critical Role of Flange Standards

A gasket must perfectly match the flange it's intended to seal. Industrial standards govern these dimensions to ensure interchangeability and safety. Merely knowing the pipe size is not enough.

Why Standards Dictate Fit

Flange standards define the gasket's required inner diameter (ID), outer diameter (OD), and bolt hole pattern. A gasket that matches the nominal pipe size but not the flange standard will not fit or seal correctly.

Common International Standards

The most prevalent standards you will encounter are:

- ASME B16.20: The American standard for metallic gaskets for pipe flanges.

- EN 1514-1: The European standard for non-metallic flat gaskets.

- DIN 2690: A German standard for flanges and their joints.

Always verify which standard your system uses before ordering.

When to Specify Custom Sizes

Custom fabrication is a standard industry practice for non-standard equipment, legacy systems, or unique flange designs that do not conform to published standards.

Understanding the Trade-offs

While highly versatile, PTFE envelope gaskets have specific characteristics that make them ideal for some applications and less suitable for others. Understanding these trade-offs is crucial for proper selection.

Strength vs. Chemical Resistance

The genius of an envelope gasket is its combination of materials. It pairs the near-total chemical inertness of the PTFE envelope with the mechanical strength and compressibility of a core insert material (like non-asbestos or rubber).

This design provides a robust seal in corrosive environments where a simple PTFE gasket might deform under pressure.

Installation Sensitivity

The primary limitation of PTFE is its tendency to "creep" or "cold flow" under high mechanical load. Overtightening the flange bolts can damage the envelope and compromise the seal.

It is critical to follow specified torque values during installation to compress the gasket sufficiently for a seal without crushing the PTFE.

Cost vs. Longevity

These are premium gaskets. The cost is higher than that of simple rubber or fiber gaskets. However, in applications involving aggressive chemicals, their long service life and resistance to degradation provide a superior total cost of ownership by reducing downtime and replacement frequency.

How to Select the Right Gasket

Use the following guidelines to ensure you specify the correct gasket for your system's unique demands.

- If your primary focus is a standard industrial application: First, identify the flange standard (e.g., ASME B16.5 Class 150) and then select the gasket with the corresponding nominal pipe size (e.g., DN50 / 2").

- If you are dealing with aggressive chemicals: The PTFE envelope is the correct choice, but you must also verify that the inner core material is compatible with your process temperature and pressure.

- If you have damaged or non-standard flanges: Choose a thicker gasket (e.g., 3mm) to better conform to surface irregularities, and be prepared to provide precise ID, OD, and bolt hole measurements for a custom-fabricated part.

- If you are replacing an existing gasket: Carefully measure the old gasket's dimensions and check for any stamped markings that indicate its original standard, size, and material.

Properly matching the gasket's size and standard to your flange is the foundational step for achieving a safe and reliable long-term seal.

Summary Table:

| Dimension | Standard Range | Key Details |

|---|---|---|

| Nominal Pipe Size (DN) | DN15 (1/2") to DN2000 (80") | Corresponds to pipe bore; must match flange standard. |

| Overall Thickness | 1 mm to 10 mm | Compensates for flange surface imperfections. |

| PTFE Envelope Thickness | Typically 0.5 mm | Provides chemical resistance; available in milled or slit styles. |

| Flange Standards | ASME B16.20, EN 1514-1, DIN 2690 | Dictates ID, OD, and bolt hole pattern for a proper fit. |

Need a Reliable, Leak-Free Seal for Your Critical Application?

KINTEK specializes in manufacturing high-precision PTFE components, including custom PTFE envelope gaskets for the semiconductor, medical, laboratory, and industrial sectors. We ensure your gasket perfectly matches your flange standard and application requirements, from prototype to high-volume production.

We provide:

- Precision Manufacturing: Guaranteed dimensional accuracy for a perfect fit.

- Custom Fabrication: Tailored sizes and thicknesses for non-standard or legacy equipment.

- Material Expertise: The right combination of PTFE envelope and core material for your chemical and pressure needs.

Achieve a superior seal and reduce downtime—contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components