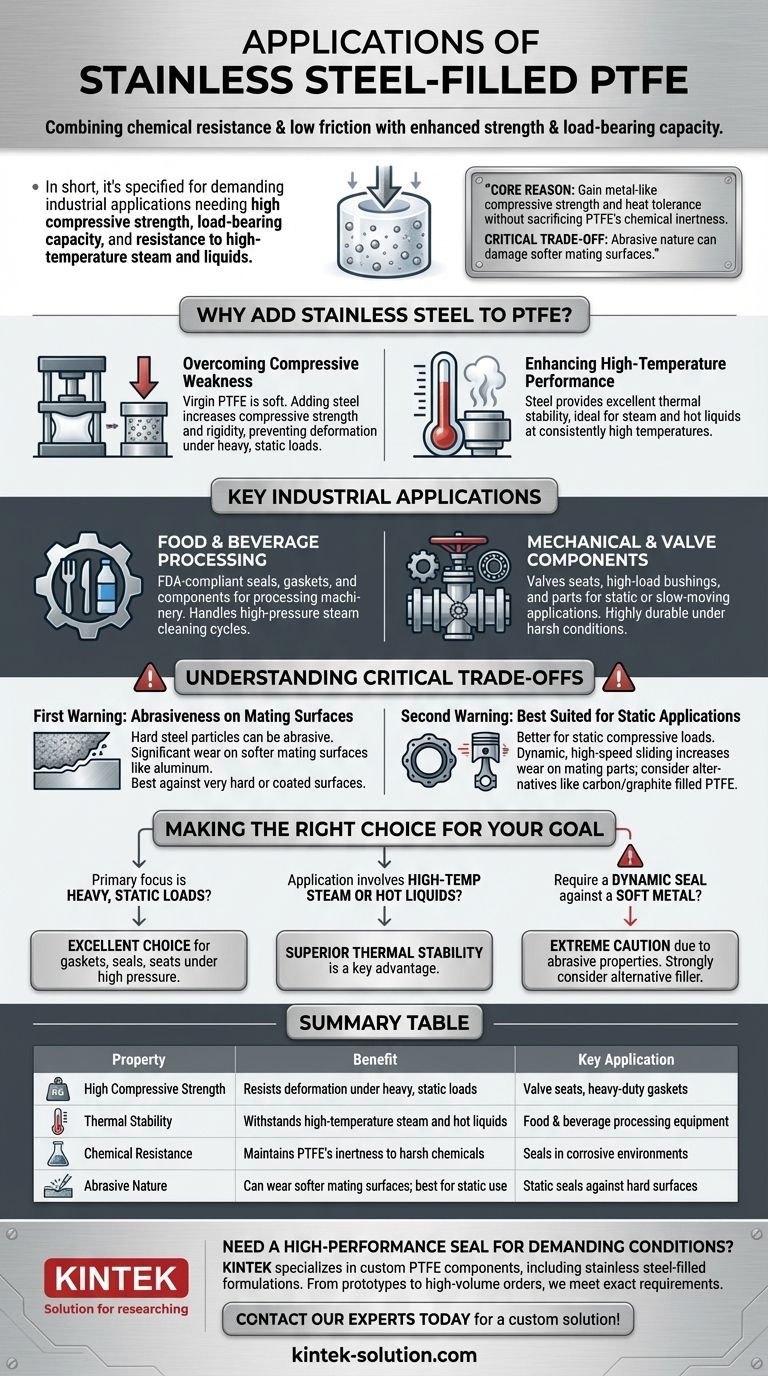

In short, stainless steel-filled PTFE is specified for demanding industrial applications where the chemical resistance and low friction of PTFE must be combined with significantly enhanced strength, load-bearing capacity, and resistance to high-temperature steam and liquids. It is commonly used for components like valve seats, seals, and gaskets in the food, beverage, and heavy mechanical industries.

The core reason to choose stainless steel-filled PTFE is to gain metal-like compressive strength and heat tolerance without sacrificing the fundamental chemical inertness of PTFE. However, this strength comes with a critical trade-off: its abrasive nature can damage softer mating surfaces.

Why Add Stainless Steel to PTFE?

Polytetrafluoroethylene (PTFE) is an exceptional polymer, but in its virgin state, it is soft and prone to deformation under load. Adding a stainless steel filler fundamentally alters its mechanical properties to suit more demanding environments.

Overcoming Compressive Weakness

Standard PTFE can creep or deform under sustained pressure, especially at elevated temperatures.

Adding powdered stainless steel to the PTFE matrix dramatically increases its compressive strength and rigidity. This allows the material to withstand heavy, static loads without losing its shape or sealing capability.

Enhancing High-Temperature Performance

While PTFE has a high melting point, its useful service temperature can be limited by its mechanical softness.

The inclusion of stainless steel provides excellent thermal stability, making the composite ideal for applications involving steam and hot liquids at consistently high temperatures.

Key Industrial Applications

The unique combination of strength and resistance makes this material a problem-solver in specific industrial contexts. It excels where less robust materials would fail.

Food and Beverage Processing

Stainless steel-filled PTFE is frequently used in equipment for the food and drink sectors.

Its ability to handle high-pressure steam cleaning cycles and its suitability for FDA-compliant applications make it a reliable choice for seals, gaskets, and other components in processing machinery.

Mechanical and Valve Components

In general mechanical systems, this material is highly valued for its durability under harsh conditions.

Its high wear resistance and strength make it suitable for parts like flow control valve seats and high-load bushings, particularly in static or slow-moving applications where a robust seal is paramount.

Understanding the Critical Trade-offs

Selecting any engineering material involves balancing its benefits against its limitations. Stainless steel-filled PTFE is no exception.

Abrasiveness on Mating Surfaces

This is the most significant drawback and a critical design consideration. The hard stainless steel particles within the PTFE can act as an abrasive.

When used against softer adjacent surfaces, such as aluminum or even some steels, stainless steel-filled PTFE can cause significant wear. It performs best against very hard or specially coated surfaces.

Best Suited for Static Applications

Due to its abrasive nature, this material is a better choice for static applications where the primary forces are compressive.

In dynamic, high-speed sliding applications, the potential for wear on mating parts increases dramatically, making other filled PTFE variants (like carbon or graphite) a more suitable choice.

Making the Right Choice for Your Goal

To determine if this material is correct for your project, consider the primary operational demand.

- If your primary focus is heavy, static loads: This material is an excellent choice for gaskets, seals, and seats that must resist deformation under high pressure.

- If your application involves high-temp steam or hot liquids: Its superior thermal stability in these specific conditions is a key advantage over many other polymers.

- If you require a dynamic seal against a soft metal: You must exercise extreme caution due to its abrasive properties and strongly consider an alternative filler.

Ultimately, specifying stainless steel-filled PTFE is a decision to prioritize strength and thermal resistance for challenging industrial sealing applications.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| High Compressive Strength | Resists deformation under heavy, static loads | Valve seats, heavy-duty gaskets |

| Thermal Stability | Withstands high-temperature steam and hot liquids | Food & beverage processing equipment |

| Chemical Resistance | Maintains PTFE's inertness to harsh chemicals | Seals in corrosive environments |

| Abrasive Nature | Can wear softer mating surfaces; best for static use | Static seals against hard surfaces |

Need a high-performance seal for demanding conditions?

KINTEK specializes in manufacturing custom PTFE components, including stainless steel-filled formulations, for the semiconductor, medical, laboratory, and industrial sectors. We provide precision production from prototypes to high-volume orders, ensuring your components meet exact strength and chemical resistance requirements.

Contact our experts today to discuss your application and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications