At their core, polymers are used in drug delivery to create sophisticated systems that control how a medication is released into the body. The two most prominent applications are implantable devices, which release drugs directly at a target site over long periods, and transdermal patches, which deliver medication steadily through the skin.

The fundamental value of polymers in medicine is their ability to transform a simple drug into a controlled-release system, improving its effectiveness, reducing side effects, and enhancing patient convenience.

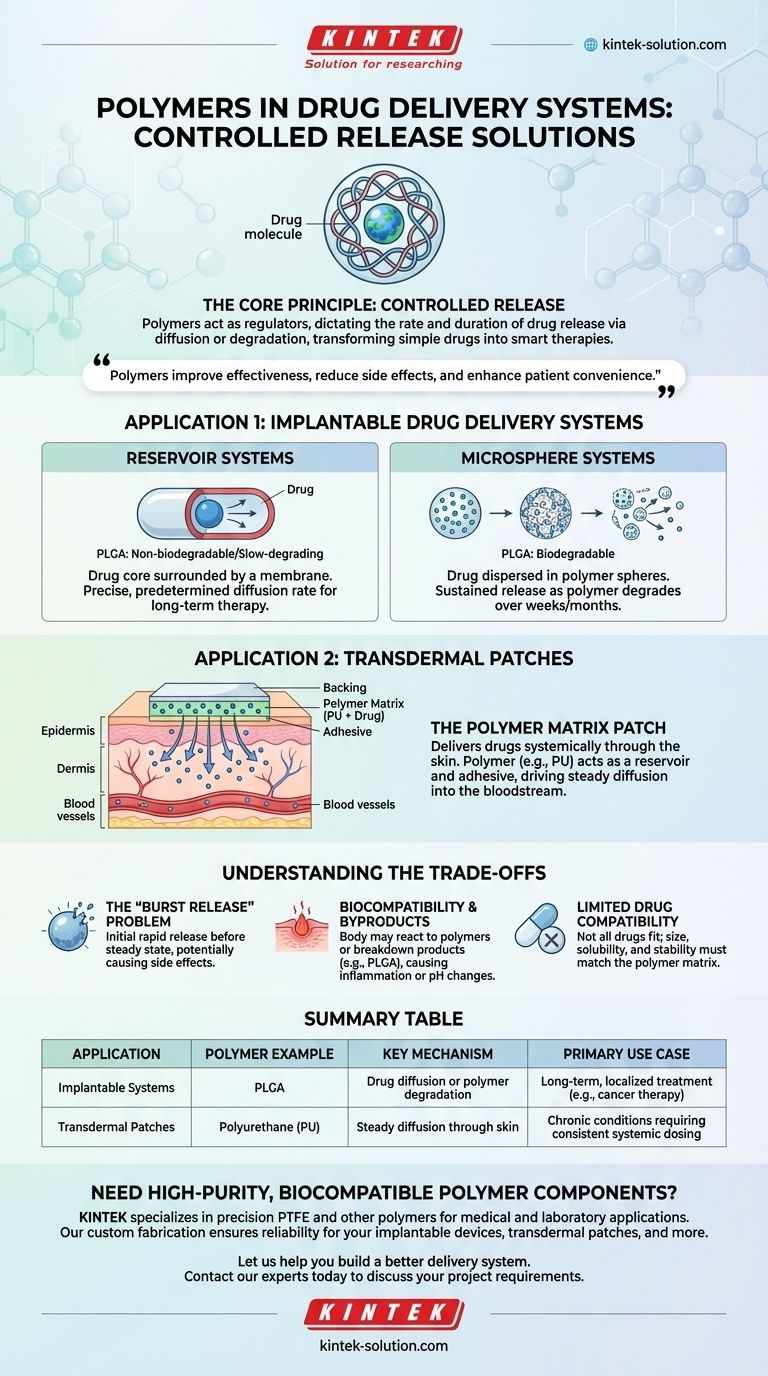

The Core Principle: Controlled Release

Why Polymers are Essential

Polymers serve as the backbone for controlled-release technology. They act as a carrier or matrix that holds the drug.

This structure is not just a container; it's a regulator. It dictates the rate and duration of the drug's release.

The Mechanism of Action

The drug is released from the polymer matrix in one of two primary ways: diffusion or degradation.

In diffusion-based systems, the drug molecules slowly pass through the polymer's molecular structure. In degradation-based systems, the polymer itself breaks down over time, releasing the trapped drug as it does.

Application 1: Implantable Drug Delivery Systems

Reservoir Systems

Reservoir systems are designed like a capsule. A core of the drug is surrounded by a non-biodegradable or slowly-degrading polymer membrane, such as PLGA (poly(lactic-co-glycolic acid)).

The drug diffuses through this polymer shell at a precise, predetermined rate. This is ideal for long-term therapies where a consistent drug level is critical.

Microsphere Systems

In this approach, the drug is evenly dispersed throughout tiny, biodegradable polymer spheres. These drug-infused microspheres are then injected or implanted.

As the polymer, often PLGA, slowly degrades in the body, it releases the drug in a sustained manner over weeks or months. This is common in hormone therapies and some cancer treatments.

Application 2: Transdermal Patches

The Polymer Matrix Patch

Transdermal patches deliver drugs systemically (to the whole body) through the skin, avoiding the digestive system.

The patch itself is a multi-layered system where the drug is mixed into a polymer matrix, such as PU (polyurethane). This polymer acts as both the drug reservoir and the adhesive that holds the patch to the skin.

Steady Diffusion into the Bloodstream

The drug concentration in the patch's polymer matrix is much higher than in the skin.

This concentration gradient drives the drug to diffuse slowly and continuously from the patch, through the skin's layers, and into the bloodstream, ensuring a steady dose.

Understanding the Trade-offs

The "Burst Release" Problem

A common challenge is the initial "burst release," where a large amount of the drug is released immediately after application or implantation before settling into its intended steady rate. This can lead to initial side effects or toxicity.

Biocompatibility and Byproducts

While medical-grade polymers are designed to be safe, the body can still react to them. For biodegradable polymers like PLGA, the breakdown products can sometimes cause localized inflammation or changes in pH.

Limited Drug Compatibility

Not all drugs are suitable for polymer-based delivery. The drug's size, solubility, and stability must be compatible with the polymer matrix and the release mechanism. High-dose medications are often impractical for these systems.

How to Apply This to Your Goal

- If your primary focus is long-term, localized treatment: Implantable systems using biodegradable polymers like PLGA are the superior choice for targeting a specific tissue while minimizing systemic exposure.

- If your primary focus is providing a steady, systemic dose for chronic conditions: Transdermal patches built on polymer matrices like PU offer a non-invasive and convenient method for consistent drug delivery.

By acting as precise and programmable carriers, polymers have fundamentally changed our ability to administer medicine effectively.

Summary Table:

| Application | Polymer Example | Key Mechanism | Primary Use Case |

|---|---|---|---|

| Implantable Systems | PLGA | Drug diffusion or polymer degradation | Long-term, localized treatment (e.g., cancer therapy) |

| Transdermal Patches | Polyurethane (PU) | Steady diffusion through skin | Chronic conditions requiring consistent systemic dosing |

Need High-Purity, Biocompatible Polymer Components for Your Drug Delivery System?

KINTEK specializes in manufacturing precision PTFE and other polymer components essential for advanced medical and laboratory applications. Whether you are developing implantable devices, transdermal patches, or other controlled-release systems, our custom fabrication services—from prototypes to high-volume production—ensure the material reliability and precision your innovation demands.

Let us help you build a better delivery system. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the features of PTFE laboratory bottles? Unmatched Chemical Resistance & Extreme Temperature Tolerance

- What are the characteristics of wide mouth PTFE laboratory bottles? Engineered for Extreme Chemical & Thermal Resistance

- Why is PTFE considered ideal for use in the food and beverage industry? Ensure Safety & Efficiency

- What are the recommended tools for CNC machining Teflon? Achieve Clean, Precise Cuts

- Why is PTFE suitable for electrical applications? Discover Its Superior Insulating Properties