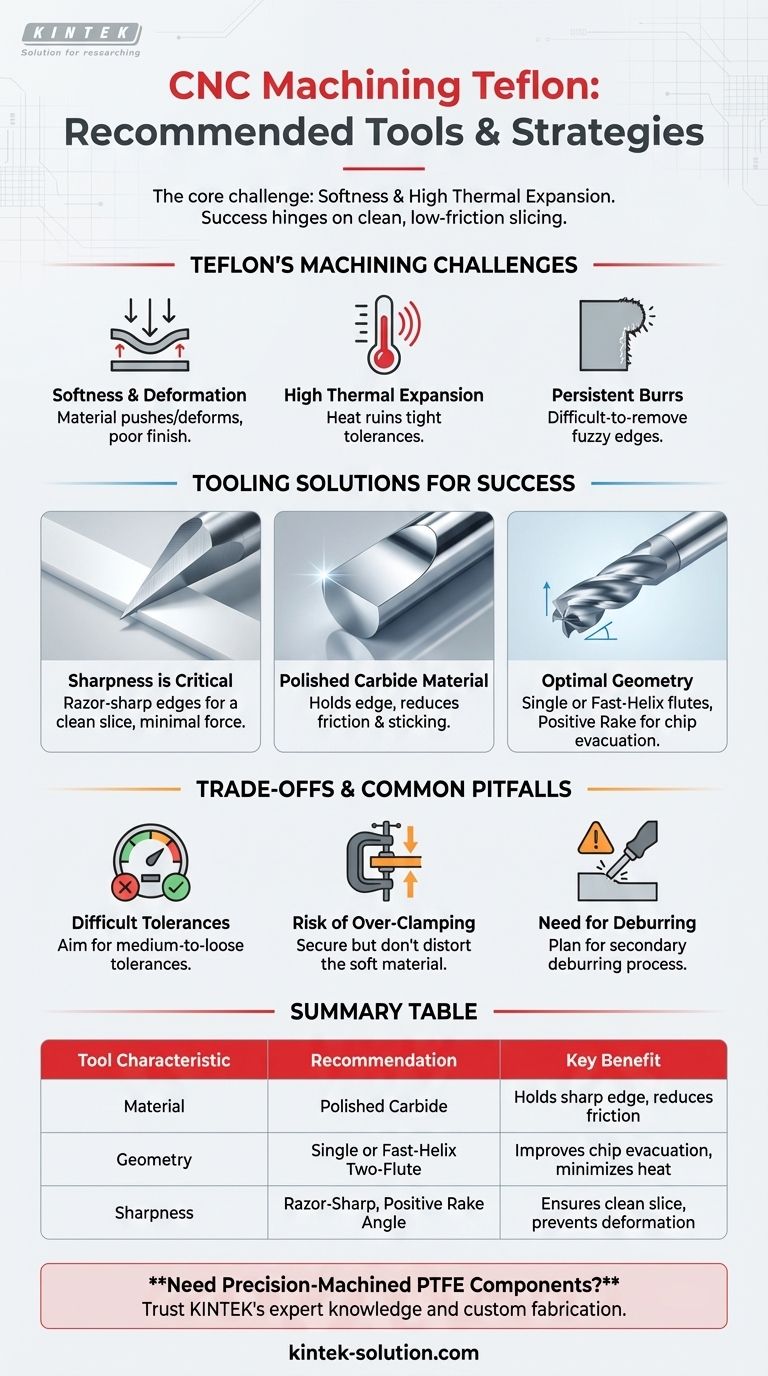

For CNC machining Teflon, the most recommended tools are extremely sharp, polished carbide cutters designed for soft materials. Tools like single-flute or fast-helix two-flute end mills are ideal because they minimize heat generation and friction, which are the primary challenges when working with this unique polymer.

Teflon's core challenge is its combination of softness and a high thermal expansion coefficient. Success hinges on a single principle: using tools and techniques that prioritize a clean, low-friction slicing action to minimize heat and prevent the material from deforming or melting.

Why Teflon Demands a Specialized Approach

Understanding the material's properties is the first step toward a successful machining outcome. Teflon (PTFE) does not behave like metals or even other plastics, presenting a unique set of obstacles.

The Challenge of Softness and Deformation

Teflon is exceptionally soft, which means it can easily be pushed away or deformed by the cutting tool rather than being cleanly cut. This can lead to chatter, poor surface finish, and dimensional inaccuracies.

A dull or improperly designed tool will plow through the material, creating more pressure than is necessary and compromising the part's geometry.

The Impact of High Thermal Expansion

Teflon expands and contracts significantly with temperature changes. The friction from a cutting tool generates heat, which can cause the material to expand mid-cut, ruining tight tolerances.

This property makes heat management one of the most critical aspects of the entire machining process.

The Persistent Problem of Burrs

Unlike materials that produce clean chips, Teflon tends to create fine, fuzzy burrs along the cut edge. These burrs are difficult to remove and can be a major source of post-processing work.

Planning a deburring strategy in advance is essential for achieving a professional-quality finished part.

Selecting the Right Cutting Tools

Your choice of tooling is the most influential factor in overcoming Teflon's machining challenges. The goal is always to reduce friction and heat at the cutting edge.

The Critical Importance of Sharpness

Absolute sharpness is non-negotiable. A razor-sharp cutting edge cleanly shears the material with minimal force, reducing pressure, heat, and the likelihood of deformation.

Dull tools will immediately cause problems, resulting in a poor surface finish and inaccurate dimensions.

Tool Material: Carbide and Polished Surfaces

Carbide cutters are highly recommended due to their ability to hold a sharp edge far longer than high-speed steel (HSS).

Furthermore, tools with highly polished surfaces and flutes are superior. A polished finish reduces friction and prevents the soft Teflon material from sticking to the tool, ensuring cleaner cuts and better chip evacuation.

Optimal Geometry: Flutes and Rake Angles

Single-flute or fast-helix two-flute cutters are ideal. These designs provide ample room for chips to be evacuated quickly, preventing them from creating additional friction in the cut.

Tools with a positive rake angle promote a slicing action, which is much more effective and generates less heat than the scraping action of a neutral or negative rake tool.

Understanding the Trade-offs and Common Pitfalls

Even with the right tools, certain inherent challenges must be managed. Being aware of these trade-offs is crucial for setting realistic expectations and avoiding common failures.

The Difficulty of Holding Tight Tolerances

Due to Teflon's high thermal expansion and tendency for stress creep, holding extremely tight tolerances is a significant challenge. For this reason, it is often wise to aim for medium-to-loose tolerances whenever the design allows.

The Risk of Over-Clamping

The softness of Teflon makes it highly susceptible to being crushed or deformed by work-holding clamps. You must secure the workpiece firmly enough to prevent vibration, but not so tightly that you distort its shape before the first cut is even made.

The Need for a Deburring Strategy

Assume that burrs will be present on the finished part. Plan for a secondary deburring process, which may include carefully sanding the edges or even freezing the part to make the burrs brittle and easier to remove.

Making the Right Choice for Your Project

Your specific tooling and process decisions should align directly with your project's goals.

- If your primary focus is achieving the highest precision and best surface finish: Invest in polished, single-flute carbide end mills and use a liberal amount of water-soluble coolant.

- If your primary focus is general-purpose machining or prototyping: Sharp, high-quality two-flute cutters will perform well, but pay close attention to cutting speeds and secure clamping.

- If your primary focus is minimizing post-processing: Use the sharpest tools possible and consider multi-axis machining to finish complex features in a single setup, reducing handling and potential burr formation.

Ultimately, machining Teflon successfully comes from respecting its unique properties and selecting tools that slice cleanly while generating minimal heat.

Summary Table:

| Tool Characteristic | Recommendation | Key Benefit |

|---|---|---|

| Material | Polished Carbide | Holds a sharp edge, reduces friction |

| Geometry | Single or Fast-Helix Two-Flute | Improves chip evacuation, minimizes heat |

| Sharpness | Razor-Sharp, Positive Rake Angle | Ensures a clean slicing action, prevents deformation |

Need Precision-Machined PTFE Components?

Machining Teflon requires expert knowledge and the right tools to avoid common pitfalls like deformation, burrs, and heat-related inaccuracies. At KINTEK, we specialize in manufacturing high-quality PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors.

Our commitment to precision production and custom fabrication—from prototypes to high-volume orders—ensures your parts meet exact specifications. Let our expertise solve your PTFE machining challenges.

Contact KINTEK today for a quote and see how we can bring value to your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the key properties of solid PTFE bushings? Master Low Friction & Chemical Resistance

- What future developments are expected for Teflon O-rings? Advanced Composites & Smarter Designs

- What industries benefit from PTFE's non-stick properties? Boost Efficiency and Purity

- Are PTFE rotary shaft seals suitable for food processing applications? Ensure Superior Hygiene and Performance

- What are the two production methods for PTFE sliding bearing pads? A Guide to Manufacturing Choices

- What pressure ranges are common in oil and gas applications, and how do PTFE seals perform? Reliable Sealing from 1,500 to 25,000 PSI

- What temperature range can PTFE impellers withstand? Operate from -200°C to 260°C

- What are the primary applications of extra-thick PTFE washers (5mm – 6mm)? Critical for High-Pressure Sealing & Load-Bearing