In demanding applications, PTFE lip seals consistently outperform traditional elastomeric seals. They provide superior protection and a significantly longer lifespan by leveraging the unique properties of polytetrafluoroethylene. Their primary advantages are exceptionally low friction, a much wider operating temperature range, and near-universal chemical resistance, making them the default choice for aggressive environments where conventional seals would quickly fail.

The core advantage of a PTFE lip seal is not just one feature, but a combination of properties. Its ability to handle high speeds, extreme temperatures, and aggressive chemicals simultaneously solves the most challenging sealing problems, ultimately reducing wear, maintenance, and energy loss in critical equipment.

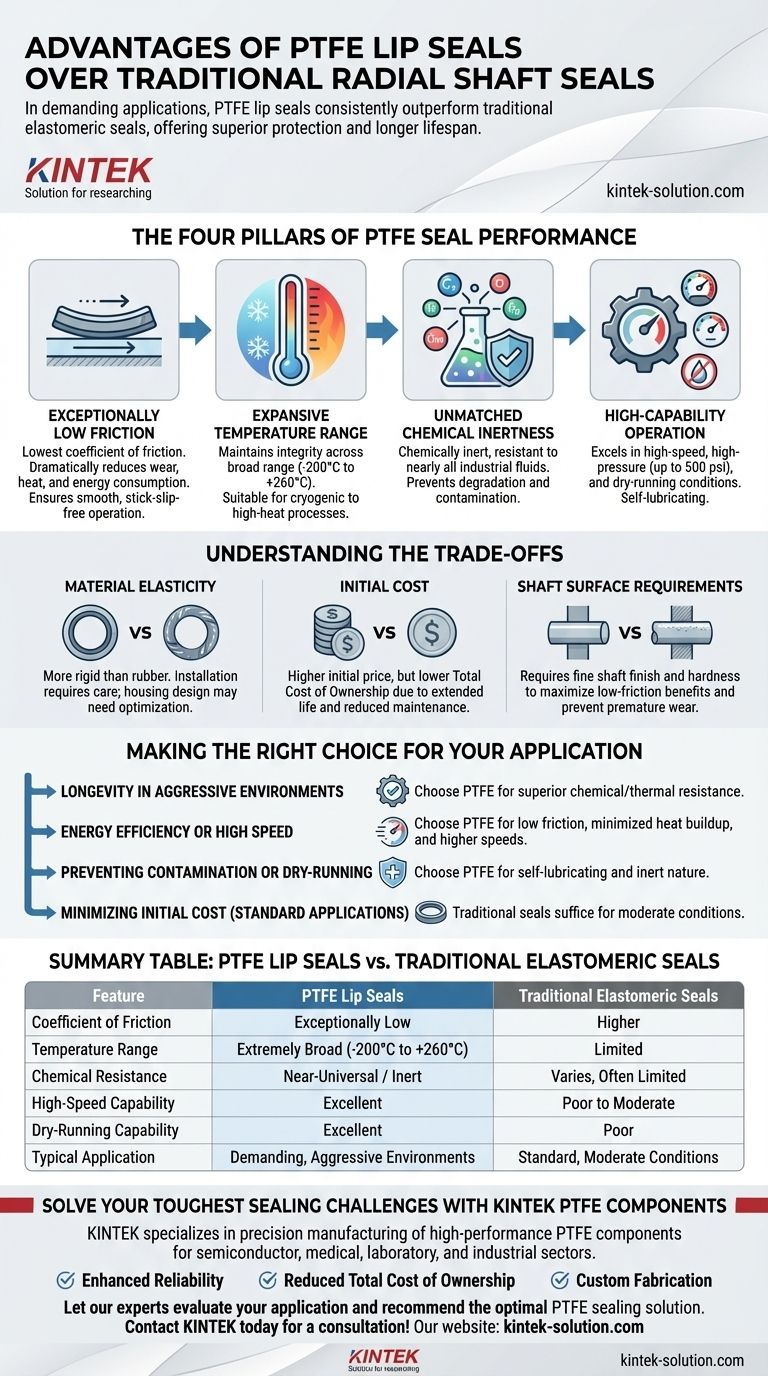

The Four Pillars of PTFE Seal Performance

The superiority of PTFE seals in harsh conditions can be attributed to four fundamental material characteristics that distinguish them from traditional rubber (elastomeric) seals.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property dramatically reduces wear on both the seal lip and the mating shaft surface.

This low friction minimizes heat generation, even at high rotational speeds. It also results in lower energy consumption and eliminates "stick-slip" behavior, ensuring smoother and more efficient operation.

Expansive Temperature Range

Traditional rubber seals have a limited operating temperature window before they become brittle at low temperatures or degrade at high temperatures.

PTFE seals, by contrast, maintain their integrity and sealing capability across an extremely broad temperature range. This makes them suitable for everything from cryogenic applications to high-heat industrial processes.

Unmatched Chemical Inertness

PTFE is chemically inert, meaning it is resistant to nearly all industrial chemicals and fluids.

Unlike elastomeric seals that can swell, harden, or degrade when exposed to aggressive media, PTFE seals remain stable. This ensures seal integrity and prevents process contamination, making them ideal for the chemical, pharmaceutical, and food processing industries.

High-Capability Operation

The combination of these properties allows PTFE seals to operate reliably under conditions that are impossible for standard seals.

They excel in high-speed applications, tolerate higher pressures (up to 500 psi), and are uniquely capable of handling dry-running or minimally lubricated conditions due to their self-lubricating nature.

Understanding the Trade-offs

While PTFE seals offer significant advantages, a complete technical evaluation requires acknowledging their specific design considerations. They are not a universal replacement for all elastomeric seals.

Material Elasticity

PTFE is a much more rigid material than rubber. It lacks the inherent elasticity of elastomers, which can make installation more sensitive.

Proper installation procedures and tools are critical to avoid damaging the seal lip. The housing design may also need to be optimized to accommodate the material's properties.

Initial Cost

PTFE lip seals typically have a higher initial purchase price compared to standard nitrile or viton seals.

This cost is justified by a lower total cost of ownership. The extended service life, reduced downtime, and lower maintenance requirements in demanding applications far outweigh the initial investment.

Shaft Surface Requirements

To leverage the full benefit of a low-friction PTFE seal, the condition of the mating shaft is critical.

The shaft surface must have a fine finish and appropriate hardness. A rough or worn shaft can cause premature wear to the PTFE lip, negating its long-life advantage.

Making the Right Choice for Your Application

To determine if a PTFE lip seal is the correct engineering choice, evaluate your primary operational challenge.

- If your primary focus is longevity in aggressive environments: A PTFE seal is the superior choice due to its chemical and thermal resistance, which prevents premature material degradation.

- If your primary focus is energy efficiency or high speed: The low-friction properties of PTFE will reduce operational torque, minimize heat buildup, and allow for higher rotational speeds than traditional seals can withstand.

- If your primary focus is preventing contamination or running without lubrication: PTFE's self-lubricating and chemically inert nature makes it ideal for dry-running, food processing, or medical applications.

- If your primary focus is minimizing initial cost for a standard application: A traditional elastomeric seal may be sufficient, provided that temperatures, speeds, and chemical exposures remain well within moderate limits.

Choosing a PTFE lip seal is an investment in system reliability, designed to solve problems that lie beyond the limits of conventional sealing technology.

Summary Table:

| Feature | PTFE Lip Seals | Traditional Elastomeric Seals |

|---|---|---|

| Coefficient of Friction | Exceptionally Low | Higher |

| Temperature Range | Extremely Broad (-200°C to +260°C) | Limited |

| Chemical Resistance | Near-Universal / Inert | Varies, Often Limited |

| High-Speed Capability | Excellent | Poor to Moderate |

| Dry-Running Capability | Excellent | Poor |

| Typical Application | Demanding, Aggressive Environments | Standard, Moderate Conditions |

Solve Your Toughest Sealing Challenges with KINTEK PTFE Components

Are PTFE lip seals the right solution for your high-speed, high-temperature, or chemically aggressive application? KINTEK specializes in the precision manufacturing of high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We help you achieve:

- Enhanced Reliability: Eliminate premature seal failure and costly downtime.

- Reduced Total Cost of Ownership: Benefit from longer service life and lower maintenance.

- Custom Fabrication: Get the exact solution you need, from prototypes to high-volume production runs.

Let our experts evaluate your application and recommend the optimal PTFE sealing solution. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components