The primary advantages of using PTFE gasket sheets stem from a unique combination of three core properties: exceptional chemical resistance, a vast operational temperature range, and a uniquely low-friction surface. This makes PTFE (Polytetrafluoroethylene) a highly reliable sealing solution for demanding industrial applications where lesser materials would quickly degrade and fail.

While many materials offer one or two key benefits, PTFE's distinct value lies in its multi-faceted resilience. It is the go-to choice for creating a stable, long-lasting seal in environments that are simultaneously chemically aggressive, subject to extreme temperatures, and require non-contaminating surfaces.

Why PTFE Excels in Demanding Environments

The fundamental strengths of PTFE make it a problem-solver for engineers and technicians dealing with challenging sealing conditions.

Unmatched Chemical Inertness

PTFE is one of the most chemically inert materials known. This means it can maintain its integrity when exposed to a very wide spectrum of aggressive acids, bases, and solvents.

This near-universal resistance makes it a default choice in chemical processing, preventing gasket degradation and ensuring a secure seal. The only common exceptions are molten alkali metals, fluorine, and some powerful oxidizing agents like nitric acid.

Extreme Temperature Stability

PTFE gaskets perform reliably across an exceptionally broad temperature range, typically from cryogenic lows of -200°C (-328°F) up to high-heat applications of +260°C (500°F).

This thermal stability ensures the gasket material will not become brittle in extreme cold or degrade in high heat, providing a consistent seal for processes with significant temperature fluctuations.

The Low-Friction Advantage

The material has an extremely low coefficient of friction, resulting in a non-stick, anti-adhesion surface.

This is highly advantageous for flanged joints that require periodic disassembly for maintenance or inspection. The gasket releases cleanly without leaving residue, reducing cleaning time and preventing damage to the flange surfaces.

Critical Properties for Specialized Applications

Beyond its core strengths, PTFE offers several other properties that make it ideal for specific, highly regulated, or sensitive industries.

Purity for Sensitive Industries

PTFE is inherently non-toxic and can be manufactured to a high degree of purity. It is FDA-approved for direct contact with food, beverages, and pharmaceuticals.

This makes it a compliant and safe choice for sanitary applications where preventing contamination is a critical operational requirement.

Superior Electrical Insulation

PTFE exhibits excellent dielectric properties, meaning it is a highly effective electrical insulator with a very low dielectric constant.

This property is crucial in applications where the gasket must prevent the flow of electrical current between two components, such as in electronic equipment or certain types of industrial machinery.

Physical Resilience and Durability

PTFE is both hydrophobic (repels water) and resistant to UV radiation, which means it will not degrade from moisture or sun exposure, making it suitable for outdoor applications.

Its conformability allows it to create a tight seal even on slightly uneven or imperfect flange surfaces, while its high fatigue resistance ensures it holds up well in dynamic conditions.

Understanding the Trade-offs

No material is perfect, and a trusted advisor must be clear about limitations. While incredibly versatile, PTFE's primary drawback is its susceptibility to creep, also known as cold flow.

The Challenge of Creep

Under sustained pressure and temperature, PTFE can slowly deform over time. This can lead to a loss of bolt torque and, eventually, a reduction in sealing pressure.

This characteristic is a critical design consideration, especially in high-pressure applications. Proper installation techniques and bolt-load management are essential to mitigate this effect. In some cases, a "filled" PTFE gasket, which incorporates materials like glass or carbon, is used to improve creep resistance.

Relative Softness

Pure PTFE is a relatively soft material. It can be easily damaged or scratched if not handled carefully during installation, which could compromise the sealing surface.

Making the Right Choice for Your Application

Selecting the right gasket material requires matching its properties to the specific demands of the service.

- If your primary focus is aggressive chemical sealing: PTFE is often the default choice due to its near-universal inertness against most industrial chemicals.

- If your application involves food, beverage, or pharmaceuticals: PTFE's FDA approval and high purity make it a safe and compliant option.

- If you are sealing a high-pressure joint without precise torque control: Be aware of PTFE's tendency to creep and consider a filled-PTFE or alternative material that offers greater rigidity.

- If your seal must operate across cryogenic and high-heat cycles: PTFE's exceptional thermal stability makes it one of the most reliable options available.

Understanding these distinct advantages and limitations allows you to specify PTFE gasket sheets with confidence where they will deliver maximum reliability.

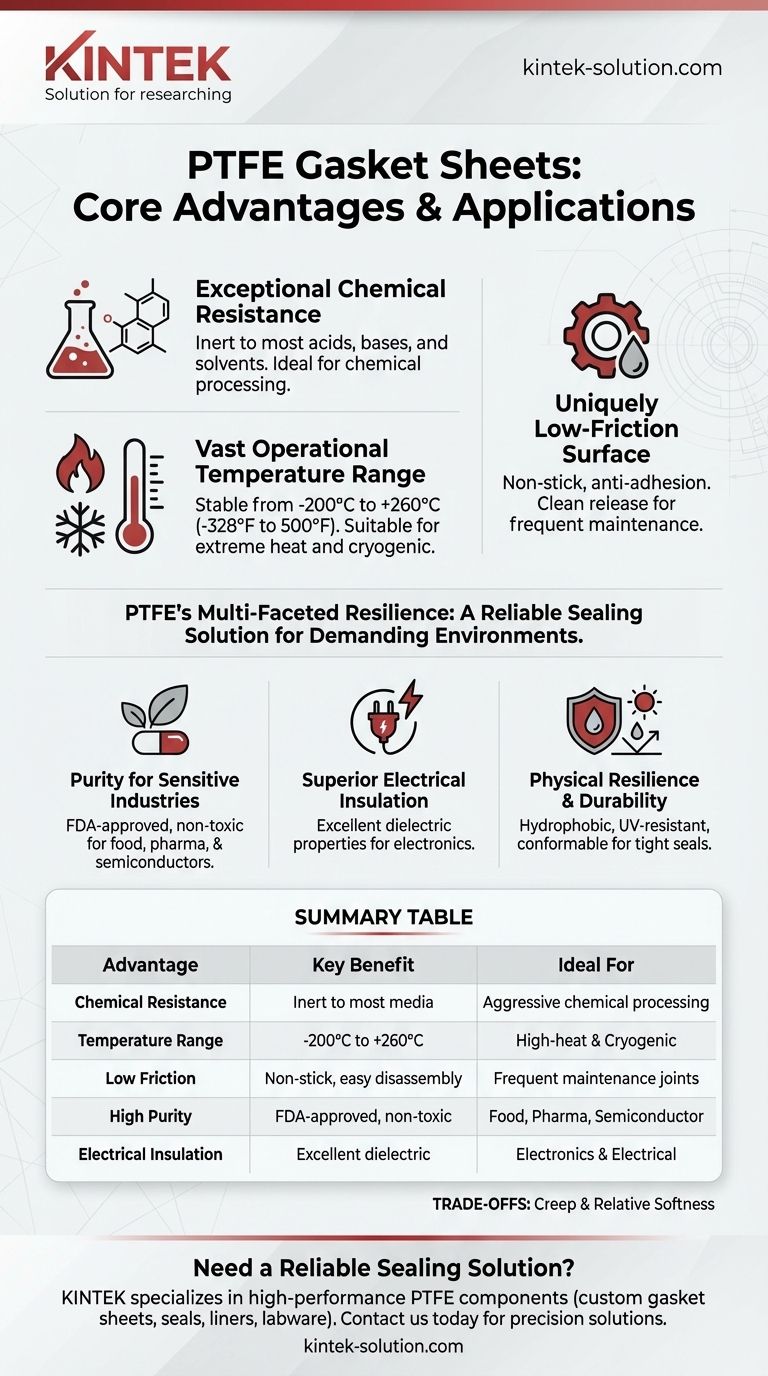

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to most acids, bases, and solvents | Chemical processing, aggressive media |

| Temperature Range | Stable from -200°C to +260°C | High-heat and cryogenic applications |

| Low Friction | Non-stick, easy disassembly | Joints requiring frequent maintenance |

| High Purity | FDA-approved, non-toxic | Food, beverage, pharmaceutical, and semiconductor industries |

| Electrical Insulation | Excellent dielectric properties | Electronics and electrical applications |

Need a reliable sealing solution for your demanding application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom gasket sheets, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors with a focus on precision and purity.

Whether you require a standard solution or a custom fabrication—from prototypes to high-volume orders—we ensure your gaskets deliver maximum reliability and longevity.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components