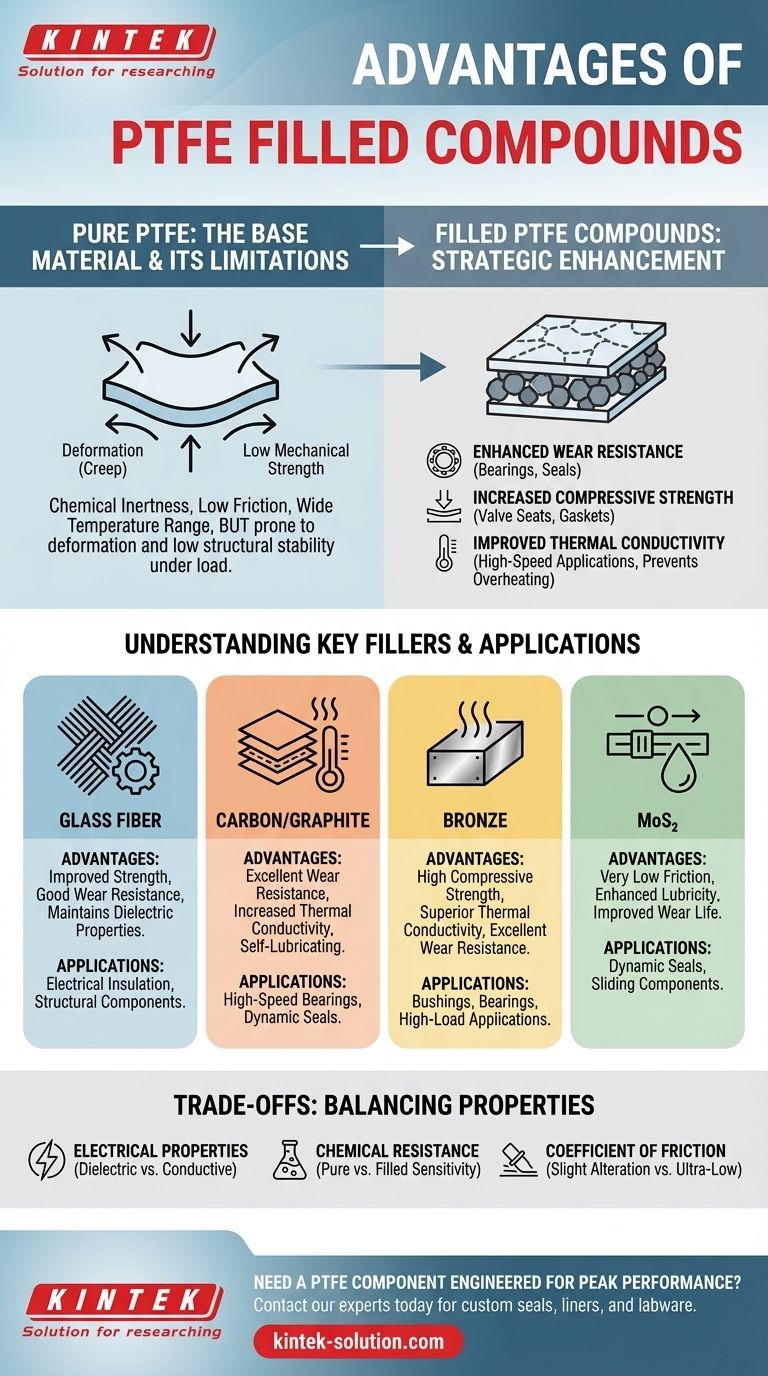

The primary advantage of using PTFE filled compounds is the ability to significantly enhance specific mechanical properties like wear resistance, compressive strength, and thermal conductivity. This process strengthens the material for demanding applications while retaining the exceptionally valuable inherent characteristics of pure PTFE, such as its chemical inertness, low friction, and wide service temperature range.

Adding fillers to Polytetrafluoroethylene (PTFE) is a strategic engineering choice. It solves PTFE's inherent weakness—deformation under load—by significantly improving its mechanical strength and wear resistance, making it suitable for demanding structural and dynamic applications where pure PTFE would fail.

Why Pure PTFE Isn't Always Enough

To understand the value of filled compounds, we must first recognize the limitations of the base material. While remarkable, pure PTFE has key weaknesses that make it unsuitable for many mechanical uses.

The Challenge of Deformation (Creep)

Pure PTFE is a relatively soft material with high flexibility. Under sustained pressure or heavy loads, it is prone to "creep," which is the tendency of a solid material to move slowly or deform permanently.

This makes it unreliable for applications requiring dimensional stability, such as high-pressure seals or structural bearings.

The Need for Mechanical Enhancement

For components like bearings, piston cups, and dynamic seals, raw performance metrics like wear resistance and compressive strength are critical. Pure PTFE lacks the rigidity and durability needed to withstand the abrasive and compressive forces present in these environments.

How Fillers Create High-Performance Compounds

Fillers are not just additives; they are strategic reinforcements blended with the PTFE base resin to target and improve specific performance characteristics.

Improving Wear and Abrasion Resistance

Fillers like glass fiber, carbon, and bronze introduce a harder, more durable phase into the PTFE matrix. This dramatically increases the material's ability to resist wear from friction and contact with other surfaces.

This enhancement is crucial for components like bearings and sliding pads that experience continuous movement.

Increasing Compressive Strength

The addition of rigid fillers provides structural support, significantly reducing the tendency of PTFE to deform under load. This results in a much higher compressive strength.

This allows filled PTFE to be used in high-load static applications, such as valve seats and gaskets, where pure PTFE would be squeezed out of shape.

Enhancing Thermal Conductivity

Pure PTFE is an excellent thermal insulator, which can be a disadvantage in high-speed applications where friction generates heat.

Fillers like bronze and carbon increase the compound's thermal conductivity. This allows heat to be drawn away from contact surfaces, preventing overheating and premature failure in dynamic seals and bearings.

Understanding the Trade-offs

Enhancing one property often involves a compromise in another. Selecting the right filled PTFE requires a clear understanding of these trade-offs.

The Impact on Electrical Properties

This is one of the most significant trade-offs. While pure PTFE is an excellent electrical insulator (dielectric), some fillers change this.

Glass-filled PTFE generally maintains good dielectric strength, but carbon-filled PTFE becomes electrically conductive, making it completely unsuitable for insulation purposes.

Potential Changes in Chemical Resistance

While PTFE itself is nearly chemically inert, the fillers are not. Fillers like bronze have poor resistance to acids and other corrosive agents.

For applications requiring ultimate chemical resistance, the choice of filler is critical, or an encapsulated design may be necessary.

Effect on Coefficient of Friction

Fillers can slightly alter the famously low coefficient of friction of PTFE. Additives like graphite and molybdenum disulfide (MoS₂) are often used specifically to lower friction even further and improve wear properties.

Selecting the Right Compound for Your Application

The choice of a PTFE compound should be driven entirely by the primary demands of your specific use case.

- If your primary focus is electrical insulation with improved strength: Glass-filled PTFE is the standard choice, as it enhances mechanical properties without sacrificing dielectric strength.

- If your primary focus is wear resistance and thermal dissipation: Carbon or bronze-filled PTFE are excellent options for high-speed bearings and dynamic applications.

- If your primary focus is the lowest possible friction for dynamic seals: A compound filled with graphite or molybdenum disulfide will provide superior lubricity and wear life.

- If your primary focus is ultimate chemical purity and resistance: Pure, unfilled PTFE or a PTFE-encapsulated O-ring remain the superior options.

By understanding the role of fillers, you can select a PTFE compound precisely engineered to meet the mechanical and environmental demands of your application.

Summary Table:

| Filler Type | Key Advantages | Ideal Applications |

|---|---|---|

| Glass Fiber | Improved strength, good wear resistance, maintains dielectric properties | Electrical insulation, structural components |

| Carbon/Graphite | Excellent wear resistance, increased thermal conductivity, self-lubricating | High-speed bearings, dynamic seals |

| Bronze | High compressive strength, superior thermal conductivity, excellent wear resistance | Bushings, bearings, high-load applications |

| MoS₂ | Very low friction, enhanced lubricity, improved wear life | Dynamic seals, sliding components |

Need a PTFE component engineered for peak performance?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and labware—precisely tailored to the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get a solution that delivers superior wear resistance, strength, and reliability.

Contact our experts today to discuss how our PTFE filled compounds can solve your specific application challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs