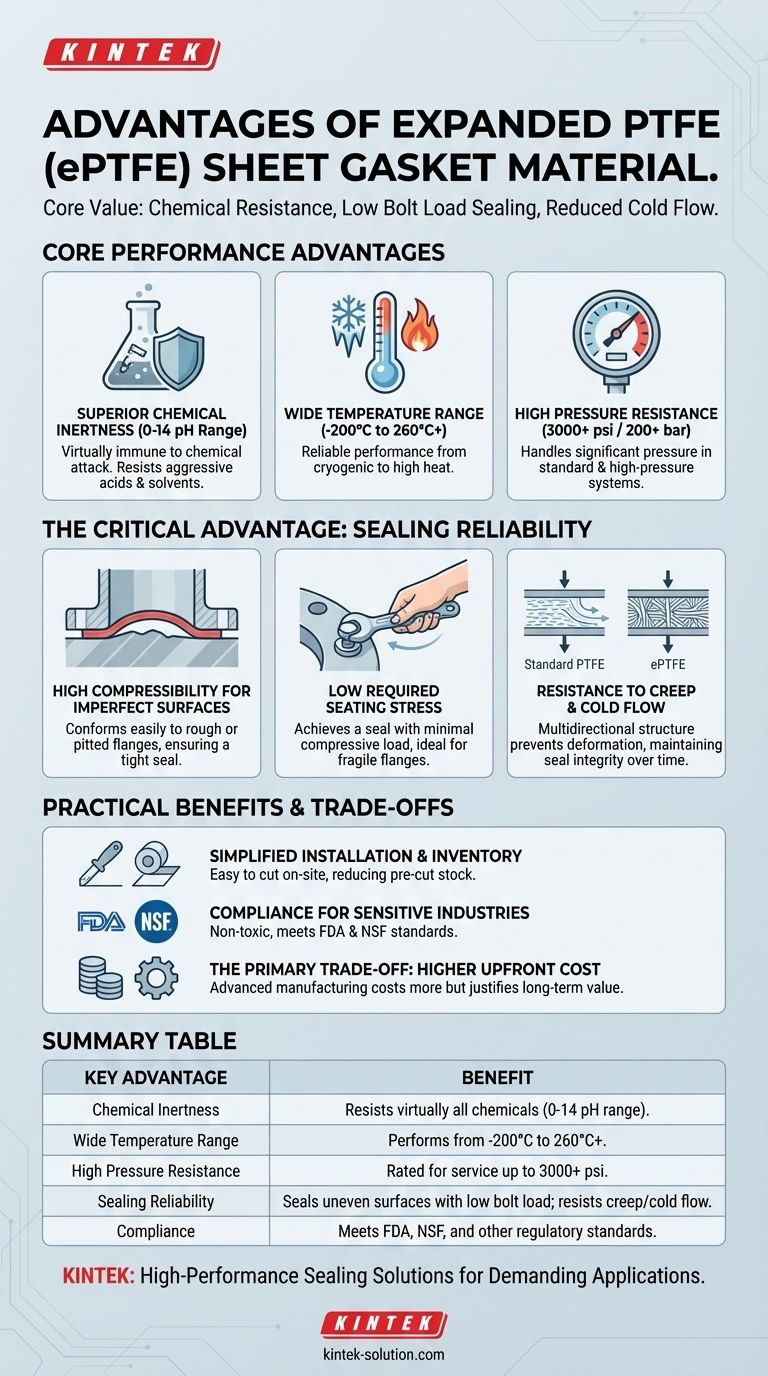

In short, the primary advantages of Expanded PTFE (ePTFE) sheet gasket material are its exceptional chemical resistance, its ability to seal reliably with low bolt load, and its significant reduction of the "cold flow" problems that affect standard PTFE. This unique combination allows it to create a durable, long-lasting seal in demanding applications involving aggressive chemicals, high temperatures, and irregular flange surfaces.

The core value of ePTFE is that it takes all the benefits of standard PTFE—like chemical inertness and a wide temperature range—and adds superior mechanical stability. This makes it a highly reliable and versatile sealing solution for the most challenging industrial environments.

Unpacking the Core Performance Advantages

ePTFE gaskets provide a level of performance that commodity gasket materials cannot match, especially when conditions are extreme.

Superior Chemical Inertness

Expanded PTFE is virtually immune to chemical attack across the entire 0-14 pH range. It will not degrade when exposed to aggressive acids, solvents, or other corrosive media.

This resistance ensures the gasket maintains its integrity, preventing leaks and extending the service life of the sealed joint.

Wide Operational Temperature Range

ePTFE performs reliably across an extremely broad temperature spectrum, from cryogenic conditions as low as -200°C (-328°F) up to 260°C (500°F), with some formulations rated even higher.

This makes it suitable for processes that involve significant temperature cycling without becoming brittle or losing its sealing capability.

High Pressure Resistance

Despite its soft and conformable nature, ePTFE is engineered to handle significant pressure. Many ePTFE sheet products are rated for service up to 3000+ psi (200+ bar).

This capability makes it a viable option for a wide range of standard and high-pressure industrial piping systems.

The Critical Advantage: Sealing Reliability

The true value of ePTFE lies in how its unique physical structure solves common sealing challenges that other materials cannot. Its manufacturing process creates a multidirectional fibrous structure that overcomes the primary weakness of standard PTFE.

High Compressibility for Imperfect Surfaces

ePTFE is highly compressible and conforms easily to rough, pitted, or uneven flange surfaces. This is a critical advantage for sealing older equipment or delicate glass-lined flanges.

It creates a tight seal without requiring excessive bolt torque, which could damage the flange itself.

Low Required Seating Stress

The material's soft, conformable nature means it achieves a seal with very little compressive load. This makes installation faster and safer, particularly on fragile flanges made of plastic, glass, or other sensitive materials.

Resistance to Creep and Cold Flow

This is the most significant advantage over standard PTFE. Cold flow (or creep) is the tendency of a material to deform or "flow" away from a compressive load over time, which causes a loss of bolt torque and can lead to leaks.

The multidirectional fibrous structure of ePTFE resists this deformation, ensuring the gasket maintains its density and keeps the joint securely sealed over a much longer period.

Understanding the Practical Benefits & Trade-offs

Beyond its technical performance, ePTFE offers practical advantages in maintenance and compliance, but it's important to understand its primary trade-off.

Simplified Installation and Inventory

Because ePTFE sheet material is easy to cut by hand or machine, you can create a custom gasket for any shape on-site.

This versatility significantly reduces the need to stock a large inventory of pre-cut gaskets in various shapes and sizes.

Compliance for Sensitive Industries

ePTFE is inherently non-toxic and meets stringent regulatory standards. Many grades are compliant with FDA regulations for food and pharmaceutical contact and NSF standards for drinking water applications.

The Primary Trade-off: Cost

The advanced manufacturing process that gives ePTFE its superior properties also makes it more expensive than standard PTFE or other common gasketing materials like compressed non-asbestos sheets.

However, this higher upfront cost is often justified by reduced maintenance, lower risk of leaks, and longer service life in critical applications.

Making the Right Choice for Your Application

Choosing ePTFE is a decision based on the specific demands of the sealing environment.

- If your primary focus is sealing aggressive chemicals: ePTFE's near-total chemical inertness provides unmatched reliability and safety.

- If your primary focus is dealing with fragile or uneven flanges: Its high compressibility and low seating stress ensure a reliable seal without damaging equipment.

- If your primary focus is long-term reliability in critical systems: Its superior resistance to cold flow maintains a tight seal over time, minimizing retorquing and preventing costly leaks.

Ultimately, ePTFE is the definitive choice when you need to ensure a durable, leak-free seal in the most demanding process conditions.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Chemical Inertness | Resists virtually all chemicals (0-14 pH range). |

| Wide Temperature Range | Performs from -200°C to 260°C+. |

| High Pressure Resistance | Rated for service up to 3000+ psi. |

| Sealing Reliability | Seals uneven surfaces with low bolt load; resists creep/cold flow. |

| Compliance | Meets FDA, NSF, and other regulatory standards. |

Need a reliable, long-lasting seal for aggressive chemicals, high temperatures, or fragile flanges?

KINTEK specializes in the precision manufacturing of high-performance PTFE and Expanded PTFE components, including custom gaskets. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume orders.

Let us provide you with a sealing solution that ensures durability and minimizes downtime. Contact KINTEK today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications