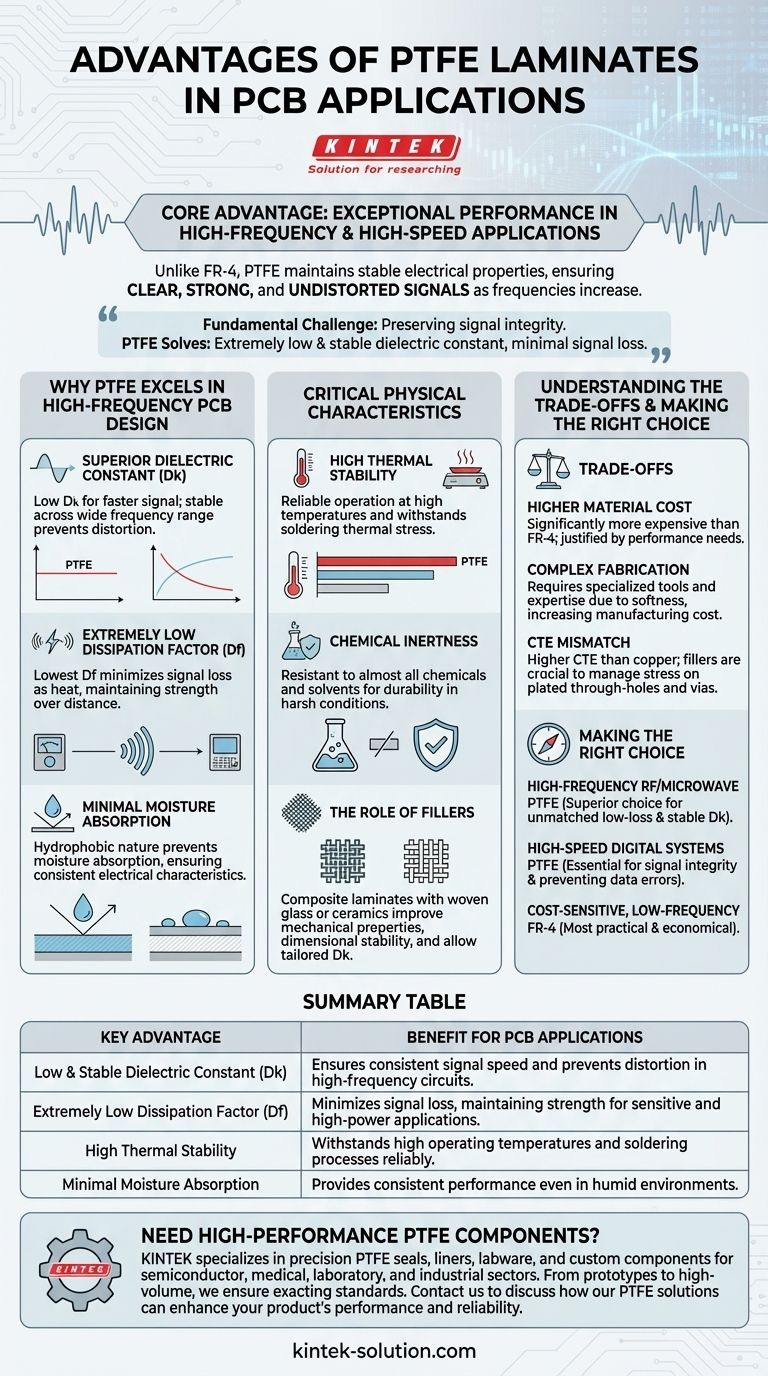

At its core, the primary advantage of using Polytetrafluoroethylene (PTFE) laminates in Printed Circuit Boards (PCBs) is their exceptional performance in high-frequency and high-speed applications. Unlike standard materials like FR-4, PTFE maintains stable electrical properties as frequencies increase, ensuring the signal traveling through the circuit remains clear, strong, and undistorted.

The fundamental challenge in high-frequency circuit design is preserving signal integrity. PTFE laminates solve this by offering an extremely low and stable dielectric constant and minimal signal loss, making them the default choice for demanding applications like RF, microwave, and high-speed digital systems.

Why PTFE Excels in High-Frequency PCB Design

Standard PCB materials begin to absorb and distort electrical signals at high frequencies, rendering them ineffective. PTFE's unique molecular structure allows it to overcome these limitations through several key electrical properties.

Superior Dielectric Constant (Dk)

The dielectric constant (Dk) of a material affects the speed at which a signal travels. PTFE's Dk is not only low (which allows for faster signal propagation) but, more importantly, it remains remarkably stable across a very wide frequency range.

This stability is critical. In materials where the Dk changes with frequency, different parts of a complex signal travel at different speeds, causing distortion and degrading performance.

Extremely Low Dissipation Factor (Df)

The dissipation factor (Df), or loss tangent, measures how much signal energy is lost as heat within the laminate. PTFE has one of the lowest Df values of any PCB material.

This minimal energy loss ensures that the signal maintains its strength as it travels across the board, a vital requirement for sensitive receivers, high-power transmitters, and long signal paths.

Minimal Moisture Absorption

PTFE is inherently hydrophobic, meaning it resists water and moisture. This is a significant advantage over materials like FR-4, which can absorb moisture from the air.

When a material absorbs moisture, its dielectric properties change, leading to unpredictable circuit performance. PTFE's resistance to moisture ensures its electrical characteristics remain consistent, even in humid environments.

Beyond Electricals: Critical Physical Characteristics

While its electrical performance is the main draw, PTFE's physical properties contribute to its overall value in high-performance electronics.

High Thermal Stability

PTFE has a very high melting point and can operate reliably at temperatures where other materials would fail. This makes it suitable for high-power applications that generate significant heat and ensures it can easily withstand the thermal stress of soldering and assembly processes.

Chemical Inertness

PTFE is highly resistant to almost all chemicals and solvents. This makes it an extremely durable substrate that can operate reliably in harsh industrial or environmental conditions without degrading over time.

The Role of Fillers

Pure PTFE is a relatively soft material. To enhance its mechanical properties for PCB fabrication, manufacturers create composite laminates by adding fillers like woven glass or ceramics.

These additives improve dimensional stability, reduce the rate of thermal expansion, and allow engineers to precisely tailor the final dielectric constant of the laminate for specific application needs.

Understanding the Trade-offs

Choosing PTFE is a decision driven by performance requirements, and it comes with important considerations. It is not a universal solution for all PCB designs.

Higher Material Cost

PTFE laminates are significantly more expensive than conventional materials like FR-4. Their use is justified only when the electrical performance requirements of the application demand it.

Complex Fabrication

The relative softness of PTFE makes it more challenging to machine. Processes like drilling, routing, and plating require specialized tools and expertise, which adds to the overall manufacturing cost compared to standard rigid boards.

Coefficient of Thermal Expansion (CTE)

PTFE has a higher CTE than the copper used for traces and planes. This mismatch can cause stress on plated through-holes and vias during temperature changes. Fillers are crucial for managing and reducing the CTE to ensure long-term reliability.

Making the Right Choice for Your Application

Selecting a PCB laminate is a foundational engineering decision that directly impacts the final performance and cost of your product.

- If your primary focus is high-frequency RF or microwave circuits: PTFE is the superior choice due to its unmatched low-loss properties and stable dielectric constant.

- If your primary focus is high-speed digital systems: A PTFE-based or similar high-performance laminate is essential to maintain signal integrity and prevent data errors.

- If your primary focus is cost-sensitive, low-frequency applications: Standard FR-4 remains the most practical and economical option.

Ultimately, choosing the right material is the first step in ensuring your electronic system performs exactly as it was designed to.

Summary Table:

| Key Advantage | Benefit for PCB Applications |

|---|---|

| Low & Stable Dielectric Constant (Dk) | Ensures consistent signal speed and prevents distortion in high-frequency circuits. |

| Extremely Low Dissipation Factor (Df) | Minimizes signal loss, maintaining strength for sensitive and high-power applications. |

| High Thermal Stability | Withstands high operating temperatures and soldering processes reliably. |

| Minimal Moisture Absorption | Provides consistent performance even in humid environments. |

Need high-performance PTFE components for your critical applications?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you receive components that meet the exacting standards required for high-frequency PCB and other demanding environments.

Contact us today to discuss how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability