The primary advantages of PTFE envelope pipe gaskets are their unique ability to combine the near-universal chemical resistance and purity of PTFE with the mechanical strength and resilience of a traditional gasket core material. This creates a high-performance seal ideal for aggressive chemical, pharmaceutical, and food-grade applications where other materials would quickly fail.

A PTFE envelope gasket solves a critical engineering problem: it provides the chemically inert, non-stick surface of solid PTFE without sacrificing the robust mechanical properties—like compressibility and bolt load retention—required for a reliable, long-lasting flange seal.

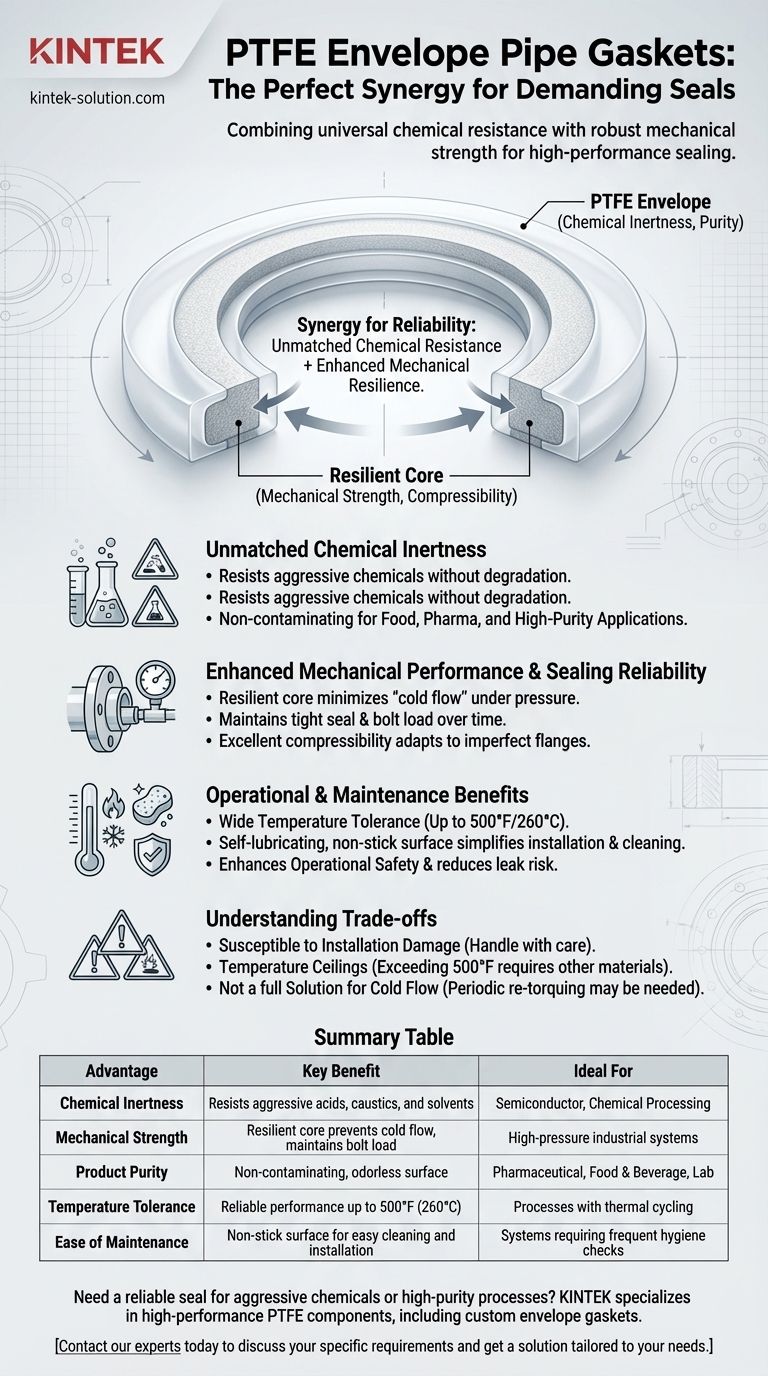

The Core Advantage: Combining Purity with Strength

The design of a PTFE envelope gasket is its main strength. A thin layer, or "envelope," of PTFE encases a more mechanically robust insert material. This creates a synergy that far exceeds the capabilities of either material alone.

Unmatched Chemical Inertness

The outer PTFE envelope is virtually inert, capable of handling the most aggressive acids, caustics, and solvents without degrading.

This non-contaminating and odorless surface makes it a default choice for high-purity applications in the food, beverage, and pharmaceutical industries, preventing any risk of media contamination.

Enhanced Mechanical Performance

While solid PTFE can be prone to "cold flow" or creep under pressure, the inner core material provides outstanding resilience and mechanical strength.

This core ensures the gasket maintains a tight seal over time by providing excellent compressibility and bolt retention, adapting to flange surface imperfections.

Superior Sealing Reliability

The combination of a soft, adaptable PTFE surface and a strong inner core allows the gasket to achieve a reliable seal across large areas, even under high pressure and bolt loading.

This robust construction ensures excellent durability, reducing the need for frequent replacements and lowering long-term maintenance costs.

Key Operational and Maintenance Benefits

Beyond its core sealing function, the PTFE envelope gasket offers several practical advantages that simplify plant operations and maintenance.

Wide Temperature Tolerance

These gaskets perform reliably across a wide operating temperature range, typically up to 500°F (260°C). This makes them suitable for processes that involve significant heat fluctuations or thermal cycling.

Simplified Installation and Cleaning

PTFE has a self-lubricating, non-stick surface. This property simplifies both installation and removal, preventing the gasket from adhering to flange faces.

This non-stick quality also prevents process media from building up on the gasket surface, which is a critical benefit for cleaning and system hygiene.

Ensured Operational Safety

By providing a durable, long-lasting seal in chemically aggressive environments, these gaskets significantly enhance operational safety and reduce the risk of hazardous leaks.

Understanding the Trade-offs

While highly effective, it's important to understand the limitations of PTFE envelope gaskets to ensure proper application.

Susceptibility to Installation Damage

The gasket's performance hinges entirely on the integrity of the thin PTFE envelope. Careless handling or over-tightening during installation can puncture or damage this layer, compromising its chemical resistance and leading to premature failure.

Temperature Ceilings

While the temperature range is wide, it is lower than that of metallic or graphite-based gaskets. For applications exceeding 500°F (260°C), other materials must be considered.

Not a Solution for Cold Flow

The inner core significantly mitigates, but does not entirely eliminate, the potential for PTFE cold flow. In high-pressure applications with significant temperature cycling, periodic re-torquing of flange bolts may still be necessary to maintain seal integrity.

Making the Right Choice for Your Application

Selecting the correct gasket is critical for system safety and efficiency. Use these guidelines to determine if a PTFE envelope gasket fits your needs.

- If your primary focus is handling aggressive chemicals: This gasket is an excellent choice, as the PTFE layer provides a nearly universal barrier against corrosive media.

- If your primary focus is product purity: For food, pharmaceutical, or electronics manufacturing, the non-contaminating, inert surface is a key advantage.

- If your primary focus is sealing imperfect or delicate flanges: The combination of a soft outer layer and a resilient core offers superior adaptability compared to hard, solid gaskets.

Ultimately, choosing a PTFE envelope gasket is an investment in reliability for your most demanding sealing challenges.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists aggressive acids, caustics, and solvents | Semiconductor, Chemical Processing |

| Mechanical Strength | Resilient core prevents cold flow, maintains bolt load | High-pressure industrial systems |

| Product Purity | Non-contaminating, odorless surface | Pharmaceutical, Food & Beverage, Laboratory |

| Temperature Tolerance | Reliable performance up to 500°F (260°C) | Processes with thermal cycling |

| Ease of Maintenance | Non-stick surface for easy cleaning and installation | Systems requiring frequent hygiene checks |

Need a reliable seal for aggressive chemicals or high-purity processes?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your gaskets deliver the chemical resistance and mechanical strength your application demands, from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How is PTFE used in industrial processes? Maximize Safety and Efficiency