The primary advantages of adding Molybdenum Disulfide (MoS2) to PTFE are a significant increase in wear resistance, surface hardness, and compressive strength. Crucially, it achieves this while acting as a secondary lubricant, which helps preserve the inherently low coefficient of friction that makes PTFE so valuable in the first place.

While virgin PTFE excels in low friction and chemical resistance, it is a relatively soft material prone to wear and deformation under load. MoS2 hardens the material to resist mechanical wear without compromising its fundamental "slipperiness," transforming it into a more durable, self-lubricating composite.

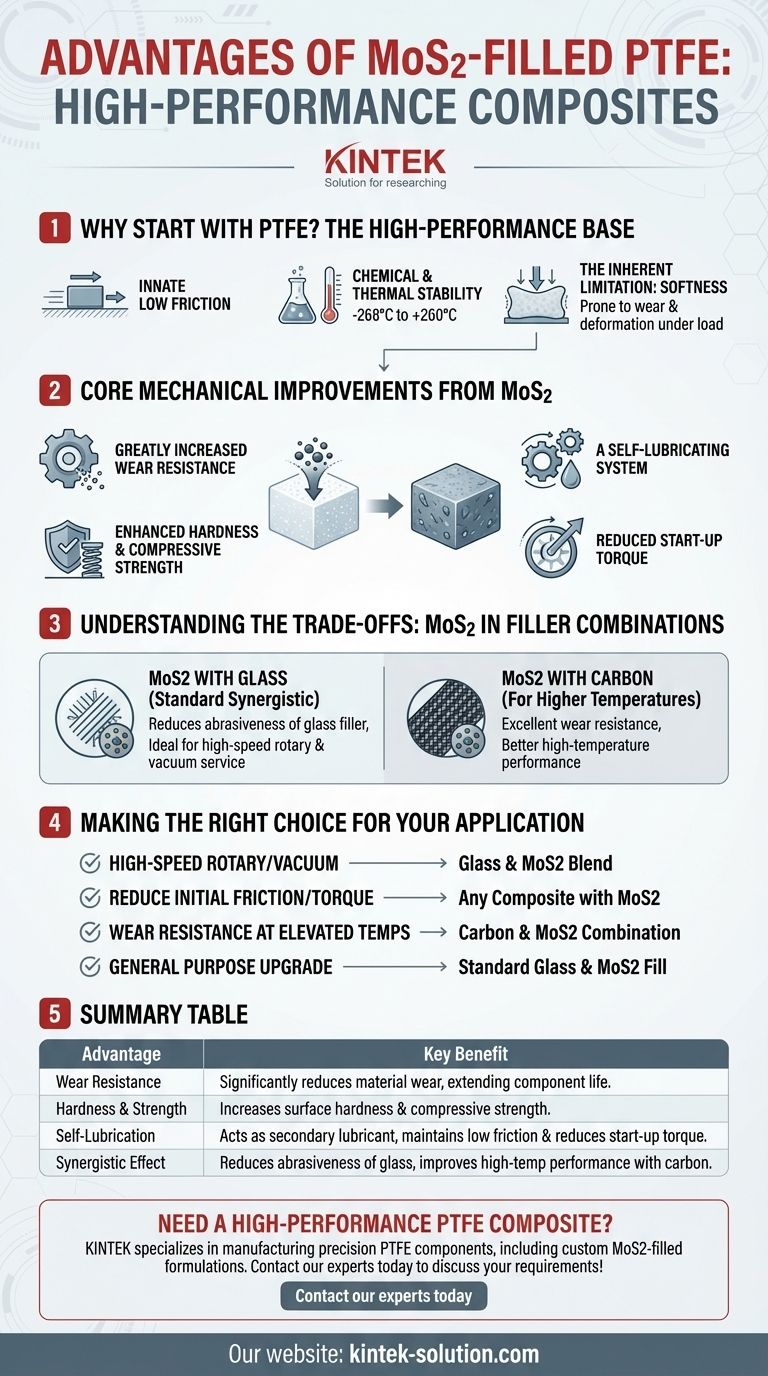

Why Start with PTFE? The High-Performance Base

To understand the role of MoS2, we must first appreciate the properties of the base material it enhances. Polytetrafluoroethylene (PTFE) is selected for demanding applications for several key reasons.

Innate Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, making it ideal for sliding and rotating applications where reducing energy loss and wear is critical.

Chemical and Thermal Stability

It is exceptionally resistant to corrosion and chemically inert to most substances. It also operates reliably across a wide temperature range, from -268°C to +260°C.

The Inherent Limitation: Softness

The primary drawback of virgin PTFE is its mechanical weakness. It is soft, has low compressive strength, and is susceptible to "creep" or deformation under sustained load, limiting its use in high-pressure or abrasive environments.

Core Mechanical Improvements from MoS2

Adding Molybdenum Disulfide directly addresses the mechanical weaknesses of virgin PTFE, making it a true engineering-grade material.

Greatly Increased Wear Resistance

MoS2 particles embedded in the PTFE matrix significantly reduce the rate at which the material wears away during sliding contact. This directly translates to longer component life.

Enhanced Hardness and Compressive Strength

The filler makes the entire composite harder and better able to withstand compressive forces without deforming. This is critical for seals, gaskets, and bearings that operate under pressure.

A Self-Lubricating System

MoS2 is a well-known solid lubricant. Its presence within the PTFE creates a self-lubricating system that maintains low friction even as the component wears, ensuring consistent performance.

Reduced Start-Up Torque

A key operational benefit is the reduction in friction upon initial movement. This lower start-up torque is especially valuable in applications with frequent start-stop cycles, reducing initial stress on drive components.

Understanding the Trade-offs: MoS2 in Filler Combinations

MoS2 is rarely used as the sole filler in PTFE. Its true value is often realized when combined with a primary structural filler like glass or carbon, where it plays a specific, synergistic role.

The Role of Primary Fillers

Fillers like glass fiber and carbon provide the bulk of the improvement in strength, stiffness, and creep resistance. However, they can also increase the friction and abrasiveness of the composite material.

MoS2 with Glass: The Synergistic Standard

A common formulation is 15% glass and 5% MoS2. The glass provides strength and durability, but it can be abrasive to softer metal mating surfaces.

The MoS2 acts as a lubricating agent that reduces the abrasiveness of the glass filler. This combination creates a strong, wear-resistant material that remains kind to its operating environment, making it ideal for high-speed rotary applications and vacuum service.

MoS2 with Carbon: For Higher Temperatures

When combined with carbon, MoS2 helps create a composite with excellent wear resistance and better high-temperature performance. This blend maintains superb dry-running capabilities, making it suitable for demanding thermal environments.

Making the Right Choice for Your Application

Selecting the correct PTFE composite depends entirely on the specific demands of your operating environment.

- If your primary focus is high-speed rotary motion or vacuum service: A blend of glass and MoS2 offers the best balance of strength, wear resistance, and low abrasiveness.

- If your primary focus is reducing initial friction and start-up torque: Any composite containing MoS2 will provide a distinct advantage over those without it.

- If your primary focus is wear resistance at elevated temperatures: A carbon and MoS2 combination is the superior choice for thermal stability.

- If your primary focus is a general-purpose upgrade over virgin PTFE: A standard glass and MoS2 fill provides a well-rounded and significantly improved mechanical profile for bearings, seals, and gaskets.

Ultimately, adding MoS2 transforms PTFE from a soft, low-friction polymer into a robust, self-lubricating composite engineered for demanding mechanical applications.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Wear Resistance | Significantly reduces material wear, extending component life. |

| Hardness & Strength | Increases surface hardness and compressive strength to resist deformation. |

| Self-Lubrication | Acts as a secondary lubricant, maintaining low friction and reducing start-up torque. |

| Synergistic Effect | When combined with glass or carbon, reduces abrasiveness and improves high-temperature performance. |

Need a high-performance PTFE composite for your application?

KINTEK specializes in manufacturing precision PTFE components, including custom MoS2-filled formulations for the semiconductor, medical, laboratory, and industrial sectors. We can help you select or fabricate the ideal composite to enhance wear resistance, reduce friction, and extend the life of your critical parts—from prototypes to high-volume production.

Contact our experts today to discuss your specific requirements and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts