The primary advantages of expanded PTFE (ePTFE) sheet are its ability to create a highly reliable, long-term seal under demanding chemical and thermal conditions. It combines the exceptional chemical inertness of standard PTFE with a unique structural stability that overcomes PTFE's inherent weakness of cold flow, or creep, under pressure.

The core problem with conventional PTFE gaskets is their tendency to "creep" or deform under load, eventually leading to leaks. Expanded PTFE solves this by transforming the material into a strong, fibrous, multi-directional structure that maintains its shape, ensuring a durable and highly conformable seal.

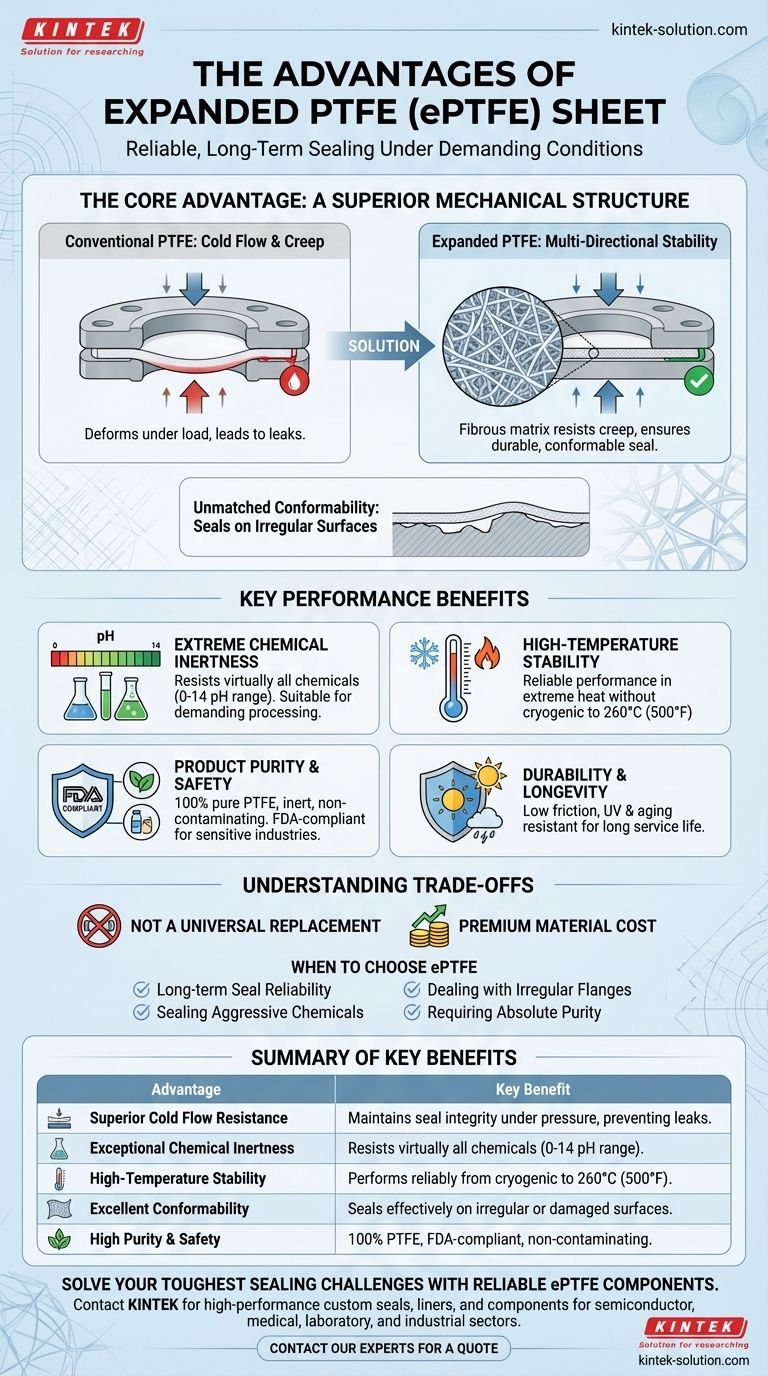

The Core Advantage: A Superior Mechanical Structure

The most significant benefit of ePTFE is not a chemical property but a mechanical one, derived directly from its manufacturing process.

The Problem with Conventional PTFE: Cold Flow

Standard PTFE is a soft material. When compressed in a flange, it can slowly deform and flow away from the point of pressure over time, especially at elevated temperatures. This phenomenon, known as cold flow or creep, reduces the sealing pressure and can ultimately cause a leak.

The Solution: Multi-Directional Expansion

Expanded PTFE is made from 100% pure PTFE that has been stretched in multiple directions. This process creates a micro-fibrous structure, similar to a web, which gives the material immense dimensional stability and strength.

This fibrous matrix physically resists the tendency to creep, allowing the gasket to maintain a consistent seal even under high bolt loads and prolonged service.

Unmatched Conformability and Tightness

The soft, flexible nature of this expanded structure allows it to conform exceptionally well to irregular or damaged flange surfaces. It effectively fills in minor pits, scratches, and imperfections, ensuring an extremely tight and reliable seal where a more rigid gasket might fail.

Key Performance Benefits in Application

Beyond its structural superiority, ePTFE retains all the well-known advantages of the base polymer.

Extreme Chemical Inertness

ePTFE sheet can handle a vast range of aggressive chemicals across the entire 0-14 pH range. The only notable exceptions are molten alkali metals and elemental fluorine, making it suitable for the most demanding chemical processing applications.

High-Temperature Stability

This material performs reliably across a wide operational temperature range, from cryogenic levels up to 260°C (500°F). This high thermal stability ensures it does not degrade or become brittle in extreme process conditions.

Product Purity and Safety

Because it is 100% pure PTFE, the material is chemically inert and non-contaminating. It will not discolor or leach into the end product, making it FDA-compliant and ideal for high-purity applications in the food, beverage, and pharmaceutical industries.

Durability and Longevity

ePTFE inherits PTFE's extremely low coefficient of friction, which reduces wear. It is also completely resistant to aging and degradation from UV light or weathering, ensuring a long and predictable service life.

Understanding the Trade-offs

While highly effective, ePTFE is a specialized material, and its selection requires understanding its context.

Not a Universal Replacement

Expanded PTFE is a "soft" gasket material. While it excels at sealing flanges on equipment like glass-lined steel vessels, it is not intended to replace spiral-wound or other metal gaskets in extremely high-pressure piping applications where gasket blowout is a primary concern.

Cost Consideration

The complex manufacturing process makes expanded PTFE a premium material. Its cost is higher than conventional PTFE or many other common gasketing materials. This investment is justified by its superior performance, reduced maintenance, and enhanced safety in critical applications.

When to Choose Expanded PTFE Sheet

Use this guide to determine if ePTFE is the right solution for your specific needs.

- If your primary focus is long-term seal reliability: Choose ePTFE for its unmatched resistance to cold flow, which prevents leaks and reduces the need for re-torquing bolts.

- If you are sealing aggressive chemicals: ePTFE provides a nearly universal solution, ensuring compatibility and safety across the full pH spectrum.

- If you are dealing with irregular or imperfect flange surfaces: The material's exceptional conformability creates a tight seal where more rigid gaskets would likely fail.

- If your application requires absolute purity: ePTFE's inert, non-contaminating properties are essential for food, pharmaceutical, and sensitive chemical processes.

Ultimately, choosing expanded PTFE is an investment in reliability and safety for your most critical sealing applications.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Cold Flow Resistance | Maintains seal integrity under pressure, preventing leaks. |

| Exceptional Chemical Inertness | Resists virtually all chemicals across the 0-14 pH range. |

| High-Temperature Stability | Performs reliably from cryogenic temperatures up to 260°C (500°F). |

| Excellent Conformability | Seals effectively on irregular or damaged flange surfaces. |

| High Purity & Safety | 100% PTFE, FDA-compliant, non-contaminating for sensitive industries. |

Ready to solve your toughest sealing challenges with reliable ePTFE components?

At KINTEK, we specialize in manufacturing high-performance expanded PTFE seals, liners, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures you get a durable, long-lasting seal that resists cold flow and harsh chemicals, reducing maintenance and enhancing safety.

Whether you need a prototype or a high-volume order, we deliver custom solutions tailored to your exact requirements.

Contact our experts today to discuss your application and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F