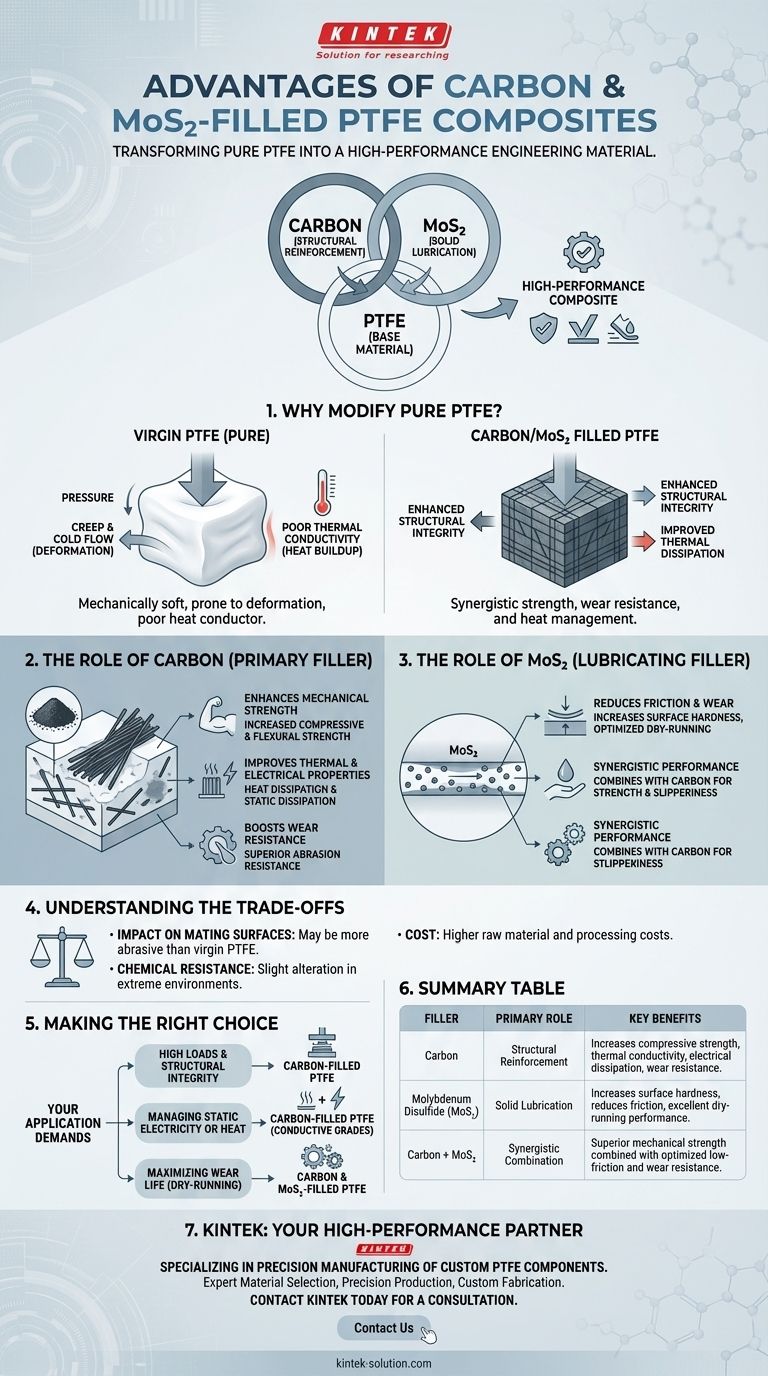

At its core, filling PTFE with carbon and molybdenum disulfide (MoS₂) transforms it from a relatively soft material into a high-performance engineering composite. This combination dramatically improves mechanical strength, wear resistance, and performance under load, particularly at higher temperatures, while retaining PTFE’s signature low-friction, dry-running capabilities.

The fundamental advantage is a synergistic one: carbon provides a strong structural backbone that resists deformation and dissipates heat, while MoS₂ acts as a solid lubricant that enhances surface hardness and further reduces wear.

Why Modify Pure PTFE?

To appreciate the role of these fillers, we must first acknowledge the limitations of pure, or "virgin," PTFE. While known for its extreme chemical inertness and low friction, it has significant drawbacks.

The Weakness of Unfilled PTFE

Virgin PTFE is mechanically soft. Under pressure, it is prone to creep and cold flow, meaning it will deform permanently over time.

It is also a poor thermal conductor, which can lead to heat buildup at the contact surface in dynamic applications, further accelerating wear and deformation.

The Role of Carbon as a Primary Filler

Adding carbon, typically in fiber or powder form, is a foundational method for overcoming PTFE's inherent mechanical weaknesses. It provides a robust internal structure.

Enhancing Mechanical Strength

Carbon significantly increases the compressive strength and load resistance of PTFE. This makes the material far less susceptible to deformation under heavy loads.

The composite material gains improved flexural strength, making it more durable in components that experience bending forces.

Improving Thermal and Electrical Properties

Carbon is an excellent thermal conductor. This property allows the filled PTFE to dissipate frictional heat away from the contact surface, improving performance and lifespan, especially at high speeds.

It also imparts electrical conductivity, making the material static dissipative. This is critical in applications where an electrical charge buildup could be problematic or dangerous.

Boosting Wear Resistance

The structural improvements from carbon directly translate to superior wear resistance. The material can withstand abrasive forces far better than virgin PTFE, especially in dry, water, and steam applications.

The Role of MoS₂ as a Lubricating Filler

Molybdenum disulfide (MoS₂) is a well-known solid lubricant. While carbon provides the strength, MoS₂ fine-tunes the tribological (friction and wear) properties.

Reducing Friction and Wear

MoS₂ primarily acts as a lubricant, increasing the material's surface hardness and wear resistance without a significant negative impact on the coefficient of friction.

It creates a transfer film on the mating surface that further reduces friction, which is especially effective in dry-running conditions.

Synergistic Performance

MoS₂ is rarely used alone in PTFE. Its true value emerges when combined with a structural filler like carbon or glass, creating a multi-faceted composite that is both strong and slippery.

Understanding the Trade-offs

While highly advantageous, using fillers is not without its considerations. An objective analysis requires acknowledging the potential downsides.

Impact on Mating Surfaces

Filled PTFE variants, including carbon-filled grades, can be more abrasive than virgin PTFE. The choice of the mating surface material is critical to prevent premature wear of the component running against the PTFE.

Chemical Resistance

While carbon itself is highly resistant, the addition of any filler can slightly alter the near-universal chemical inertness of pure PTFE. This is only a concern in the most aggressive chemical environments.

Cost

Adding high-performance fillers like carbon and MoS₂ increases the raw material and processing costs compared to virgin PTFE. The performance benefits must justify the added expense.

Making the Right Choice for Your Application

The decision to use a specific filled PTFE should be driven entirely by the demands of the application.

- If your primary focus is high loads and structural integrity: Carbon-filled PTFE is the superior choice due to its exceptional compressive strength and resistance to deformation.

- If your primary focus is managing static electricity or heat: The thermal and electrical conductivity of carbon-filled grades makes them essential for static-dissipative and heat-sensitive applications.

- If your primary focus is maximizing wear life in demanding, dry-running conditions: The combination of Carbon and MoS₂ provides a synergistic effect, using carbon for strength and MoS₂ for enhanced surface lubrication.

By understanding the distinct roles of each filler, you can select a composite material precisely engineered to meet your application's most demanding requirements.

Summary Table:

| Filler | Primary Role | Key Benefits |

|---|---|---|

| Carbon | Structural Reinforcement | Increases compressive strength, improves thermal conductivity, provides electrical dissipation, enhances wear resistance. |

| Molybdenum Disulfide (MoS₂) | Solid Lubrication | Increases surface hardness, reduces friction and wear, provides excellent dry-running performance. |

| Carbon + MoS₂ | Synergistic Combination | Superior mechanical strength combined with optimized low-friction and wear resistance for demanding applications. |

Need a High-Performance PTFE Component for Your Demanding Application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including advanced composites filled with carbon and MoS₂. We understand the critical balance of strength, wear resistance, and low friction required in industries like semiconductor, medical, laboratory, and industrial manufacturing.

We provide:

- Expert Material Selection: Guidance on choosing the right filled PTFE grade (carbon, MoS₂, or a combination) for your specific load, environmental, and performance requirements.

- Precision Production: Components manufactured to the highest tolerances for reliable, long-lasting performance.

- Custom Fabrication: From initial prototypes to high-volume production runs, we deliver solutions tailored to your exact needs.

Let us engineer a solution that enhances your product's performance and durability.

Contact KINTEK today for a consultation and let's discuss your project requirements.

Visual Guide

Related Products

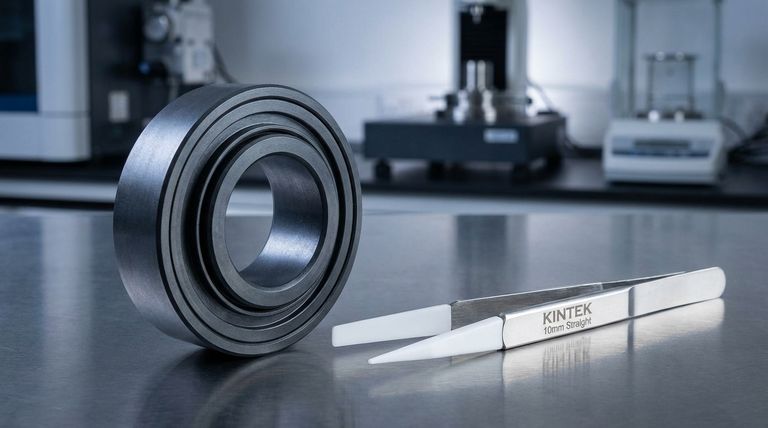

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support