In short, Virgin PTFE (Polytetrafluoroethylene) is an exceptional valve seat material for its nearly universal chemical resistance and extremely low friction, but it is limited by its poor mechanical strength and its tendency to deform under load, a phenomenon known as creep.

The decision to use Virgin PTFE hinges on a critical trade-off: you gain elite chemical and thermal performance at the cost of mechanical robustness. It excels in low-pressure, corrosive environments but fails in high-pressure applications or where dimensional stability is paramount.

The Unmatched Advantages of Virgin PTFE Seats

Virgin PTFE became a standard in many industries for a reason. Its unique combination of properties makes it the default choice for specific, demanding applications.

Unrivaled Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, including strong acids and alkalis. This makes it an ideal lining and sealing material for highly corrosive media.

This property ensures exceptional durability and longevity in harsh chemical environments where other materials would quickly degrade.

Exceptionally Low Friction

PTFE has the lowest coefficient of friction of any known solid material. This allows it to operate without lubrication ("dry run") and eliminates "stick-slip" behavior, ensuring smooth valve actuation.

The practical benefit is a significantly smaller operating torque, which allows for smaller, more energy-efficient actuators and easier manual operation.

High-Temperature Performance

Virgin PTFE maintains its properties across a wide temperature range, with a continuous service temperature of up to 260°C (500°F).

Superior Sealing Properties

The material is sufficiently ductile to conform to valve surfaces, creating a tight, reliable seal. It also exhibits good stress recovery.

Furthermore, PTFE is hydrophobic (water-repellent) and non-wetting, which prevents media from being absorbed and compromising the seal over time.

Understanding the Critical Trade-offs

The same molecular structure that gives PTFE its benefits also creates significant mechanical limitations. Ignoring these trade-offs is a common cause of valve failure.

Vulnerability to Cold Flow (Creep)

This is the most significant disadvantage of Virgin PTFE. Under sustained pressure, especially at elevated temperatures, the material will slowly deform and "flow" away from the pressure point.

This creep can lead to a loss of sealing pressure and eventual valve leakage, making it unsuitable for applications with high, constant loads.

Limited Mechanical Strength

Virgin PTFE has low tensile strength and poor impact resistance compared to other polymers.

It is generally not recommended for pressures exceeding 5 ksi (345 bar), as the seat can be physically extruded or damaged.

Poor Thermal Properties

While it has a high-temperature ceiling, PTFE has poor thermal conductivity, meaning it doesn't dissipate heat well.

It is also sensitive to rapid or large temperature fluctuations. Changes greater than 167°F (75°C) can cause dimensional changes that compromise the seal.

Susceptibility to Other Stresses

PTFE degrades quickly when exposed to radiation, with a very low maximum lifetime dose.

In high-pressure gas service, it can also be susceptible to explosive decompression, where trapped gas causes blistering or fracturing upon a sudden pressure release.

Making the Right Choice for Your Application

Selecting the correct seat material requires a clear understanding of your system's operational demands.

- If your primary focus is aggressive chemical media: Virgin PTFE is often the best and only choice due to its near-total chemical inertness.

- If your primary focus is low-torque or frequent actuation: PTFE's unparalleled low friction makes it ideal for automated systems or valves that must be operated quickly and easily.

- If your application involves high pressure (>5 ksi) or significant temperature cycling: Avoid Virgin PTFE. You must consider a reinforced or "filled" grade of PTFE or a different material like PEEK or metal.

- If your environment has high radiation: Do not use Virgin PTFE; it will degrade and fail prematurely.

Ultimately, understanding both the strengths and weaknesses of Virgin PTFE is the key to designing a reliable and long-lasting system.

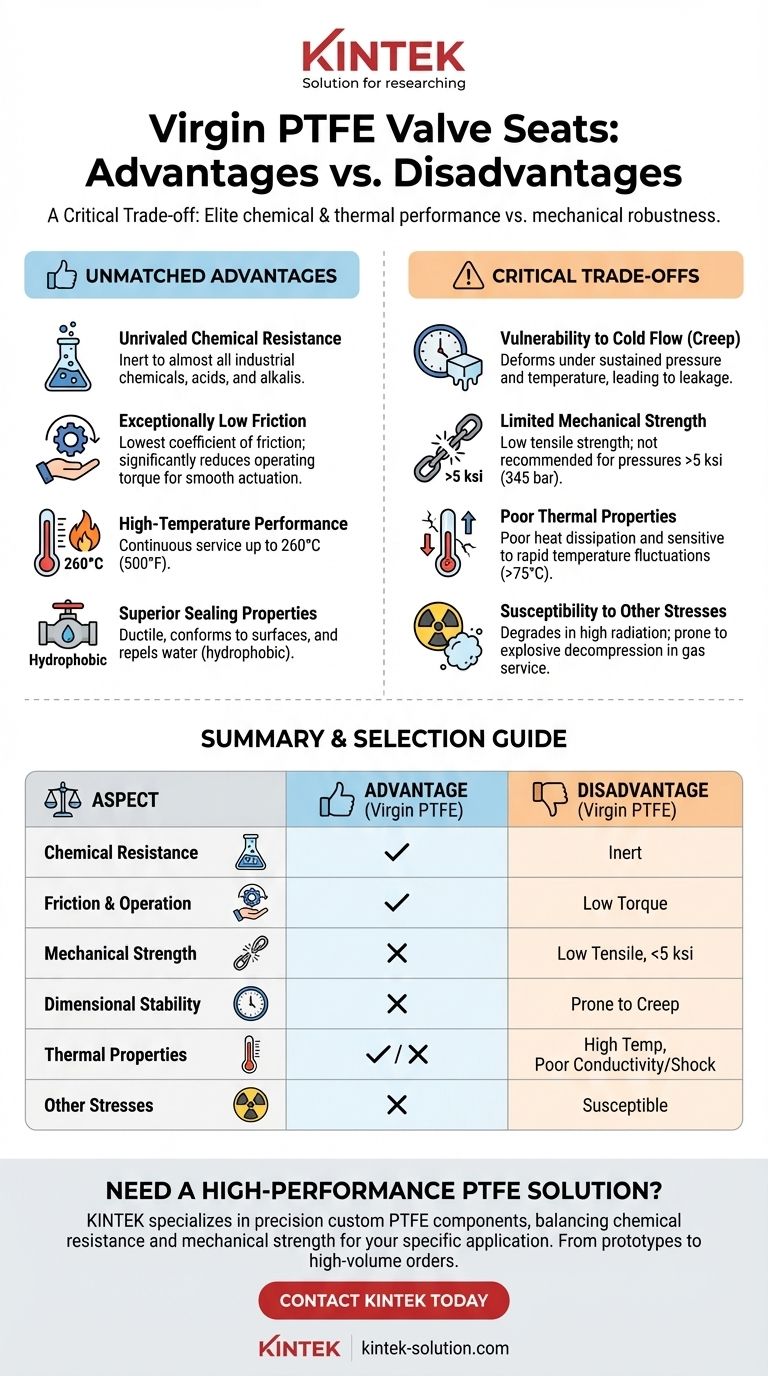

Summary Table:

| Aspect | Advantage of Virgin PTFE | Disadvantage of Virgin PTFE |

|---|---|---|

| Chemical Resistance | Unrivaled, inert to almost all chemicals | - |

| Friction & Operation | Extremely low friction, reduces operating torque | - |

| Mechanical Strength | - | Poor tensile strength, limited to ~5 ksi pressure |

| Dimensional Stability | - | Prone to cold flow (creep) under sustained load |

| Thermal Properties | High continuous temp (260°C / 500°F) | Poor thermal conductivity, sensitive to rapid temp changes |

| Other Stresses | - | Susceptible to radiation and explosive decompression |

Need a High-Performance PTFE Solution for Your Valves?

Choosing the right valve seat material is critical for system reliability and longevity. The experts at KINTEK can help you navigate these trade-offs.

We specialize in manufacturing precision PTFE components—including custom valve seats, seals, and liners—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need the pure chemical resistance of Virgin PTFE or the enhanced mechanical properties of a filled PTFE compound, we provide custom fabrication from prototypes to high-volume orders.

Let us help you design a solution that balances chemical resistance, mechanical strength, and cost-effectiveness for your specific application.

Contact KINTEK today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers