In the simplest terms, a static application is one where there is no movement between the parts being sealed. A PTFE O-Ring in this context acts as a gasket, creating a reliable, long-term barrier between two fixed surfaces. It is primarily chosen for its exceptional resistance to corrosive chemicals and extreme temperatures, making it a critical component in demanding industrial and medical environments.

The core challenge in a static application is ensuring a perfect, leak-proof seal between non-moving components. PTFE O-Rings solve this by providing unmatched chemical inertness, making them the default choice for sealing aggressive media where standard rubber seals would fail.

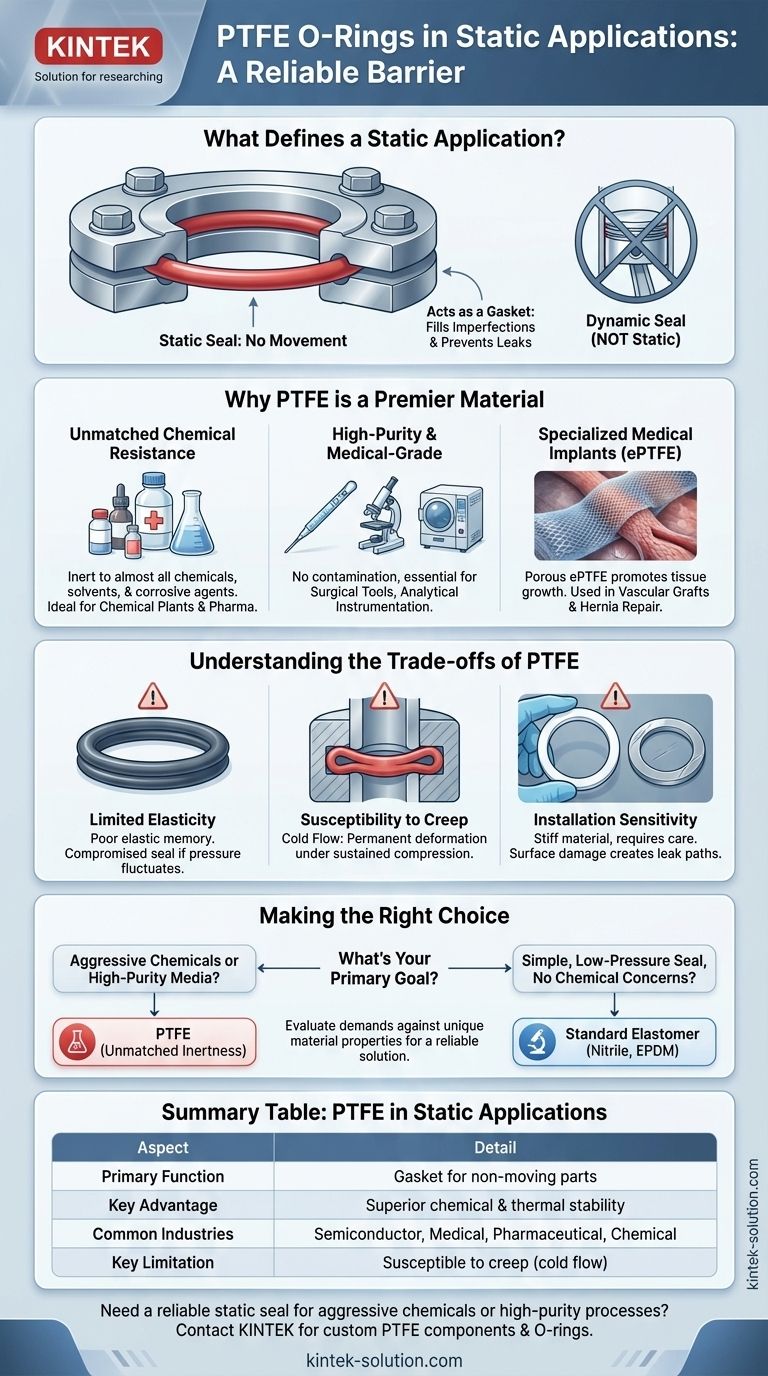

What Defines a Static Application?

A deep understanding of static sealing is crucial for ensuring the integrity and safety of a system. The concept is straightforward but has important implications for material selection.

The Absence of Motion

The defining characteristic of a static seal is the complete lack of movement between the sealing surfaces and the O-ring itself.

Think of two pipe flanges bolted together or the faceplate on a piece of scientific equipment. The O-ring is compressed into a groove between these two stationary faces and remains there for its entire service life.

This is the direct opposite of a dynamic seal, where parts are in motion, such as a piston moving inside a cylinder.

Functioning as a Gasket

In these applications, the O-ring is often referred to as a gasket. Its sole purpose is to fill the microscopic imperfections between two surfaces, creating a physical barrier that prevents the leakage of fluids or gases.

The seal's effectiveness depends on the material's ability to resist the contained media and maintain its compressed shape over time.

Why PTFE is a Premier Material for Static Seals

While many materials can create a static seal, PTFE (Polytetrafluoroethylene) is specified when performance and reliability are non-negotiable.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, solvents, and corrosive agents. This makes it an essential material for applications in chemical plants and pharmaceutical processing.

Where a standard rubber O-ring would quickly degrade, a PTFE seal maintains its integrity, preventing catastrophic leaks.

High-Purity and Medical-Grade Applications

In the medical and life sciences fields, material purity is paramount. PTFE seals are used in surgical tools, autoclaves, and analytical instrumentation like UHPLC systems.

They do not contaminate the media they are in contact with, which is critical for patient safety and accurate scientific analysis.

Specialized Medical Implants (ePTFE)

A unique form, expanded PTFE (ePTFE), has a porous, mesh-like structure. This property is leveraged in medical implants where the goal is tissue integration.

The body's own tissue can grow into the porous ePTFE, making it ideal for vascular grafts and hernia repair. This is a highly specialized static application where biocompatibility and structure are the key drivers.

Understanding the Trade-offs of PTFE

No material is perfect. While PTFE offers elite performance in certain areas, its physical properties create specific limitations that must be understood.

Limited Elasticity

Unlike rubber, solid PTFE is a rigid material with very poor elastic memory. Once compressed, it does not spring back to its original shape effectively.

This means that any relaxation in the bolted joint or pressure fluctuation can potentially compromise the seal.

Susceptibility to Creep

Under sustained compression and temperature, PTFE can be subject to creep, or cold flow. This is a slow, permanent deformation of the material.

Engineers must account for creep in the design of the gland (the groove the O-ring sits in) to ensure the seal remains energized over its intended lifespan.

Installation Sensitivity

The stiffness of solid PTFE O-rings can make them more challenging to install than their flexible rubber counterparts. Care must be taken to avoid scratching or deforming the ring during assembly, as any surface damage can create a leak path.

Making the Right Choice for Your Application

Selecting the correct sealing material requires a clear understanding of your primary operational goal.

- If your primary focus is sealing aggressive chemicals or high-purity media: PTFE is often the only viable choice due to its near-universal chemical inertness.

- If your application is for a permanent medical implant: Specialized forms like ePTFE are required for their unique porous structure that promotes tissue integration.

- If you need a simple, low-pressure seal with no chemical concerns: A standard elastomer like Nitrile or EPDM is often a more cost-effective and forgiving solution.

By evaluating the demands of the application against the unique properties of the material, you ensure a reliable and safe sealing solution.

Summary Table:

| Aspect | Static PTFE O-Ring Application |

|---|---|

| Primary Function | Acts as a gasket to seal non-moving parts |

| Key Advantage | Superior chemical resistance and thermal stability |

| Common Industries | Semiconductor, Medical, Pharmaceutical, Chemical Processing |

| Key Limitation | Susceptible to creep (cold flow) under sustained compression |

Need a reliable static seal for aggressive chemicals or high-purity processes?

At KINTEK, we specialize in manufacturing precision PTFE components, including O-rings, seals, and custom labware. Our expertise ensures your critical applications in the semiconductor, medical, and laboratory industries are protected with components that offer unmatched chemical inertness and performance.

We provide custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific requirements.

Contact us today to discuss your static sealing needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs