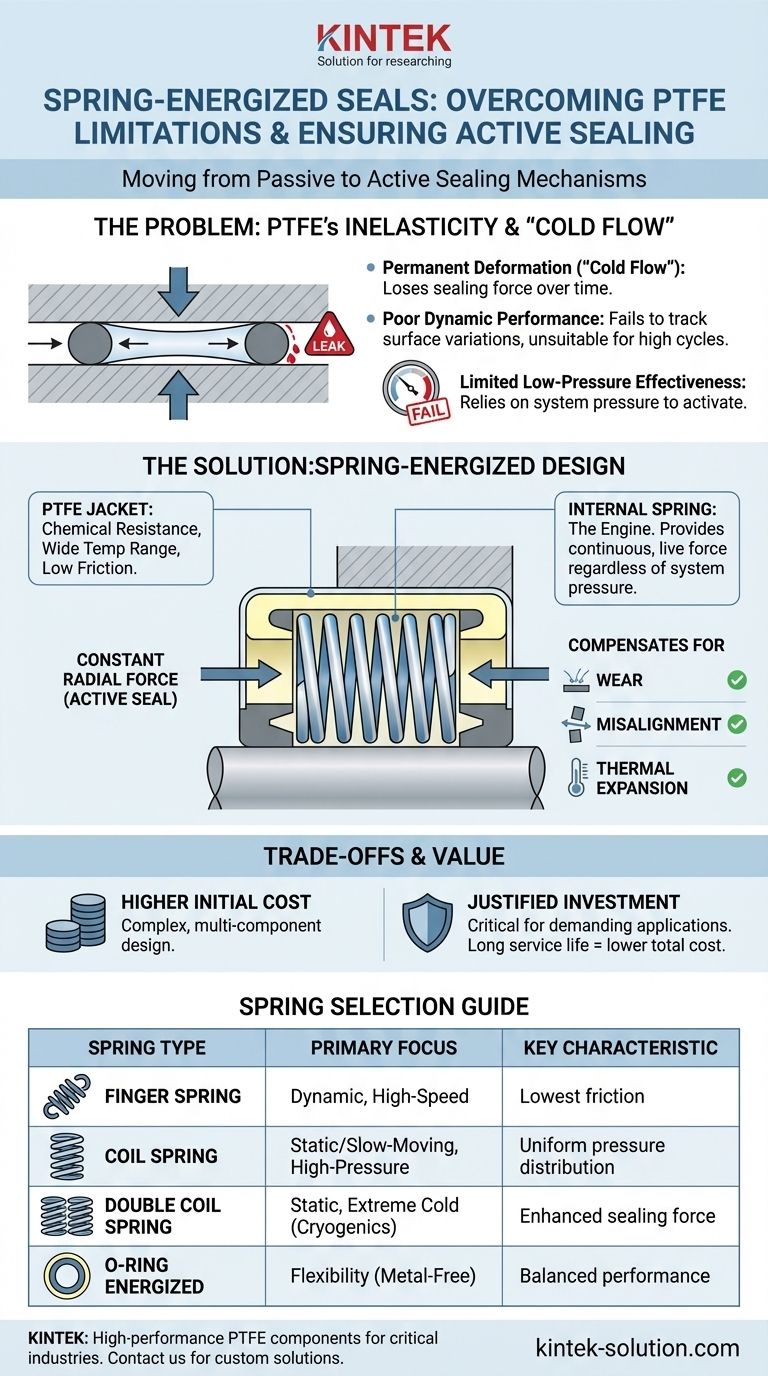

At their core, spring-energized seals are composite designs that pair a polymer jacket, typically made of PTFE, with an internal metallic spring. They directly solve the primary weakness of standard PTFE seals and O-rings: their inherent inelasticity, or inability to "spring back" after being compressed. This internal spring provides a constant, live force, ensuring the seal remains in contact with the sealing surfaces even under fluctuating temperatures, pressures, or mechanical wear.

The fundamental difference is a shift from a passive to an active sealing mechanism. While a standard PTFE O-ring relies solely on system pressure to create a seal, a spring-energized seal uses its internal spring to maintain a constant, reliable sealing force, dramatically improving performance in demanding and dynamic conditions.

The Fundamental Problem with PTFE as a Sealing Material

To understand the value of a spring-energized design, we must first examine the inherent limitations of Polytetrafluoroethylene (PTFE) when used alone in sealing applications.

The Issue of "Cold Flow" and Inelasticity

PTFE is a remarkably low-friction and chemically inert material, but it is not a true elastomer. When compressed, it tends to deform permanently rather than returning to its original shape.

This tendency, known as cold flow or creep, means that a simple PTFE O-ring can lose its sealing force over time, especially after a pressure cycle.

Poor Performance in Dynamic Applications

In applications with moving parts, this lack of "memory" is a significant liability. A standard PTFE seal may not adequately track variations in the hardware surfaces, leading to leaks.

Its inability to rebound makes it unsuitable for high cycle rates or applications that require repeated installation and removal.

Limited Effectiveness at Low Pressures

Many seal designs rely on system pressure to "activate" them, pushing the seal lip against the hardware. At very low pressures, a standard PTFE seal may not have enough force to create a reliable seal on its own.

How a Spring-Energized Design Changes Everything

The spring-energized seal is an engineered solution that retains the benefits of PTFE while systematically eliminating its weaknesses.

The Role of the PTFE Jacket

The outer jacket provides the primary interface with the system. It delivers the exceptional chemical resistance, wide temperature tolerance, and low-friction properties that PTFE is known for.

The Function of the Internal Spring

The internal spring is the engine of the seal. It acts as an energizer, providing a constant radial force that presses the lips of the PTFE jacket outwards.

This continuous force ensures the seal lips are always in contact with the gland and rod/bore surfaces, regardless of system pressure.

Creating a Consistent, Active Seal

The spring's energy compensates for the PTFE's weaknesses. It actively adjusts for seal wear, gland misalignment, and thermal expansion or contraction.

This creates a robust, leak-tight seal across a massive range of conditions, from cryogenic temperatures to extreme heat and from deep vacuums to high pressures.

Understanding the Trade-offs

While highly effective, spring-energized seals are a specialized solution, and their use involves clear trade-offs.

Higher Initial Cost

These are complex, multi-component seals that are more expensive to manufacture than simple elastomeric or PTFE O-rings.

Justifying the Investment

The higher cost is justified in critical applications where seal failure would result in costly downtime, safety hazards, or system contamination.

Their long service life and reliability in extreme environments often provide a lower total cost of ownership compared to repeatedly replacing conventional seals.

Material and Spring Selection is Critical

The performance of the seal is highly dependent on choosing the right jacket material and spring type for the specific application's media, temperature, and motion. This is not a one-size-fits-all solution.

Making the Right Choice for Your Application

Selecting the correct spring type is essential for optimizing performance based on your specific operational demands.

- If your primary focus is dynamic, high-speed applications: Choose a Finger Spring design, which provides good sealing with the lowest friction.

- If your primary focus is static or slow-moving, high-pressure sealing: A Coil Spring offers more uniform pressure distribution for the tightest seal.

- If your primary focus is static sealing in extreme cold (cryogenics): A Double Coil Spring provides enhanced, reliable sealing force in demanding thermal conditions.

- If your primary focus is balancing flexibility where a metal spring is undesirable: An O-ring Energized design can be the optimal solution.

By understanding this active sealing principle, you can specify a solution that delivers unwavering reliability where conventional designs fall short.

Summary Table:

| Spring Type | Primary Application Focus | Key Characteristic |

|---|---|---|

| Finger Spring | Dynamic, High-Speed | Lowest friction |

| Coil Spring | Static/Slow-Moving, High-Pressure | Uniform pressure distribution |

| Double Coil Spring | Static, Extreme Cold (Cryogenics) | Enhanced sealing force |

| O-ring Energized | Flexibility (Metal-Free Required) | Balanced performance |

Need a reliable sealing solution for demanding conditions? KINTEK specializes in manufacturing high-performance PTFE components, including custom spring-energized seals. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering precision from prototypes to high-volume orders. Let our expertise solve your toughest sealing challenges—contact us today to discuss your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials