In the food industry, specific applications of Teflon (PTFE) coatings range from preventing sugar cubes from sticking in molds to ensuring potato chip slicing knives remain free of residue. It is also used on cheese augers to stop crust build-up, on fast-food egg scramblers and waffle irons for easy release, and on piano wires used to cut cookie dough uniformly.

Teflon's value in food processing is not just about non-stick cookware; it's a strategic industrial solution used to enhance product quality, improve hygiene, and boost operational efficiency by solving fundamental problems of sticking, residue buildup, and friction on production equipment.

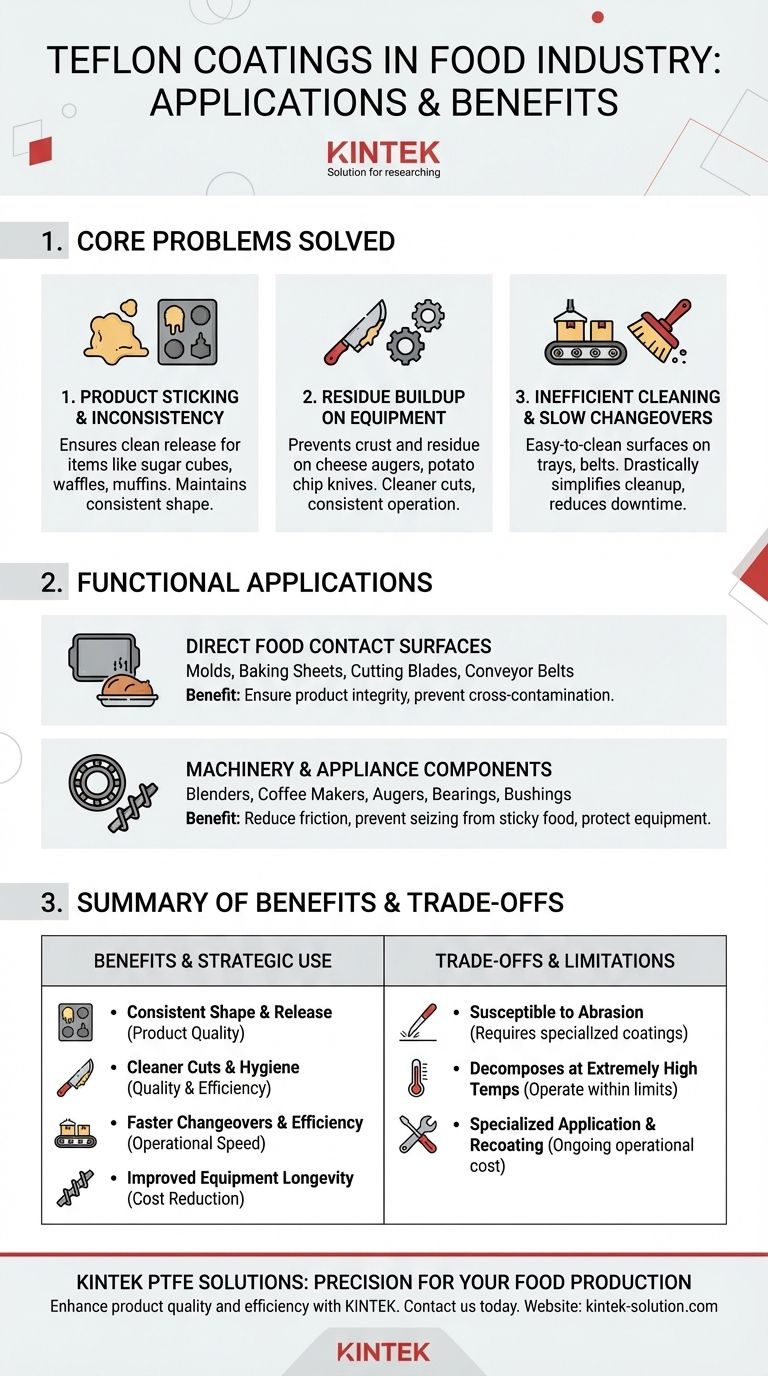

The Core Problems Teflon Solves in Food Production

Teflon's prevalence in the food industry stems from its ability to solve three persistent challenges: product adhesion, equipment contamination, and slow cleaning cycles. Its unique properties provide a direct solution to these costly operational hurdles.

Problem 1: Product Sticking and Inconsistency

Many food products, especially those with high sugar or fat content, are inherently sticky. This adhesion can ruin the product's shape, texture, and appearance.

Teflon's primary benefit is its non-stick or "release" quality. By coating molds for items like waffles, muffins, and ice-cream cones, manufacturers ensure that each product releases cleanly, maintaining a consistent and appealing shape.

Problem 2: Residue Buildup on Processing Equipment

During continuous production, food residue accumulates on machinery components. This buildup can impede mechanical function, degrade product quality, and create hygiene risks.

Applying Teflon to parts like cheese augers or potato chip slicing knives prevents this accumulation. The low-friction surface means less residue adheres, leading to cleaner cuts, more consistent operation, and reduced wear on the equipment itself.

Problem 3: Inefficient Cleaning and Slow Changeovers

Cleaning production lines is a time-consuming but critical process. Any material that can speed this up directly improves a facility's output and efficiency.

Teflon's easy-to-clean surface is a major advantage. It is often applied as liners for baking sheets and trays or directly onto conveyor belts. This prevents food from baking onto the surface, drastically simplifying cleanup and reducing downtime between production runs.

Where Teflon is Applied: A Functional Breakdown

Teflon coatings are not a one-size-fits-all solution. They are applied strategically to different parts of the production line depending on the function.

Direct Food Contact Surfaces

This is the most common category of application. The goal here is to directly influence the food product itself.

Examples include molds, baking sheets, cutting blades, and conveyor belts. The coating ensures product integrity and prevents cross-contamination from burnt-on residue.

Machinery and Appliance Components

In this role, Teflon's purpose is to protect the equipment and ensure it runs smoothly. While it may come into contact with food, the primary goal is mechanical.

This includes coating internal parts of appliances like blenders and coffee makers to prevent food clogging. In larger machinery, it is used on augers, bearings, and bushings to reduce friction and prevent seizing from sticky food buildup.

Understanding the Trade-offs and Limitations

While highly effective, Teflon coatings are not without limitations. Acknowledging these is key to making an informed decision for any industrial application.

Durability and Abrasion Resistance

Standard Teflon coatings can be susceptible to scratching and abrasion from hard tools or abrasive food particles. This can degrade the non-stick performance over time.

For high-wear environments, specialized, reinforced versions of the coating are often required, which can increase costs.

High-Temperature Stability

Food-grade Teflon is stable at typical baking and cooking temperatures. However, at extremely high temperatures (well above those used in most food processing), PTFE can begin to decompose.

It is critical to operate within the specified temperature limits of the particular coating chosen to ensure both food safety and coating longevity.

Application and Maintenance

Industrial Teflon coating is a specialized process that requires professional surface preparation and application to ensure proper adhesion and performance. It is not a simple paint.

Furthermore, recoating may be necessary as part of a regular maintenance schedule, representing an ongoing operational cost.

Applying Teflon Coatings to Your Operations

Choosing to use Teflon should be based on a clear operational goal. By identifying your primary challenge, you can determine the most effective application.

- If your primary focus is product quality and release: Prioritize coating molds, trays, and cutting surfaces to ensure consistent product shape and appearance.

- If your primary focus is operational efficiency: Implement Teflon-coated liners and conveyor belts to dramatically reduce cleaning times and speed up product changeovers.

- If your primary focus is equipment longevity: Apply coatings to high-friction mechanical parts like augers, bearings, and gears to reduce wear and prevent failure from food residue.

Ultimately, leveraging Teflon strategically allows you to turn a material science solution into a measurable improvement in production quality and efficiency.

Summary Table:

| Application | Problem Solved | Benefit |

|---|---|---|

| Molds (Waffles, Muffins) | Product Sticking | Consistent Shape & Release |

| Slicing Blades (Chips) | Residue Buildup | Cleaner Cuts & Hygiene |

| Conveyor Belts & Trays | Slow Cleaning | Faster Changeovers & Efficiency |

| Augers & Bearings | Friction & Wear | Improved Equipment Longevity |

Ready to solve your food production challenges with precision-engineered PTFE components?

KINTEK specializes in custom fabricating high-performance Teflon seals, liners, labware, and coated parts for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our focus on precision manufacturing ensures your equipment runs smoother, cleaner, and more efficiently.

Contact KINTEK today to discuss how our PTFE solutions can enhance your product quality and operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application