Beyond the frying pan, the material we know as Teflon is a high-performance polymer whose applications extend to laser printers, waterproof clothing, and even cosmetics. Its true identity is Polytetrafluoroethylene (PTFE), a synthetic fluoropolymer discovered by accident during refrigerant experiments in 1938.

Teflon's defining characteristic is not just its non-stick surface, but its extreme chemical inertness. This stability, born from a powerful carbon-fluorine bond, is what makes it an essential material in demanding industrial and technological applications far removed from the kitchen.

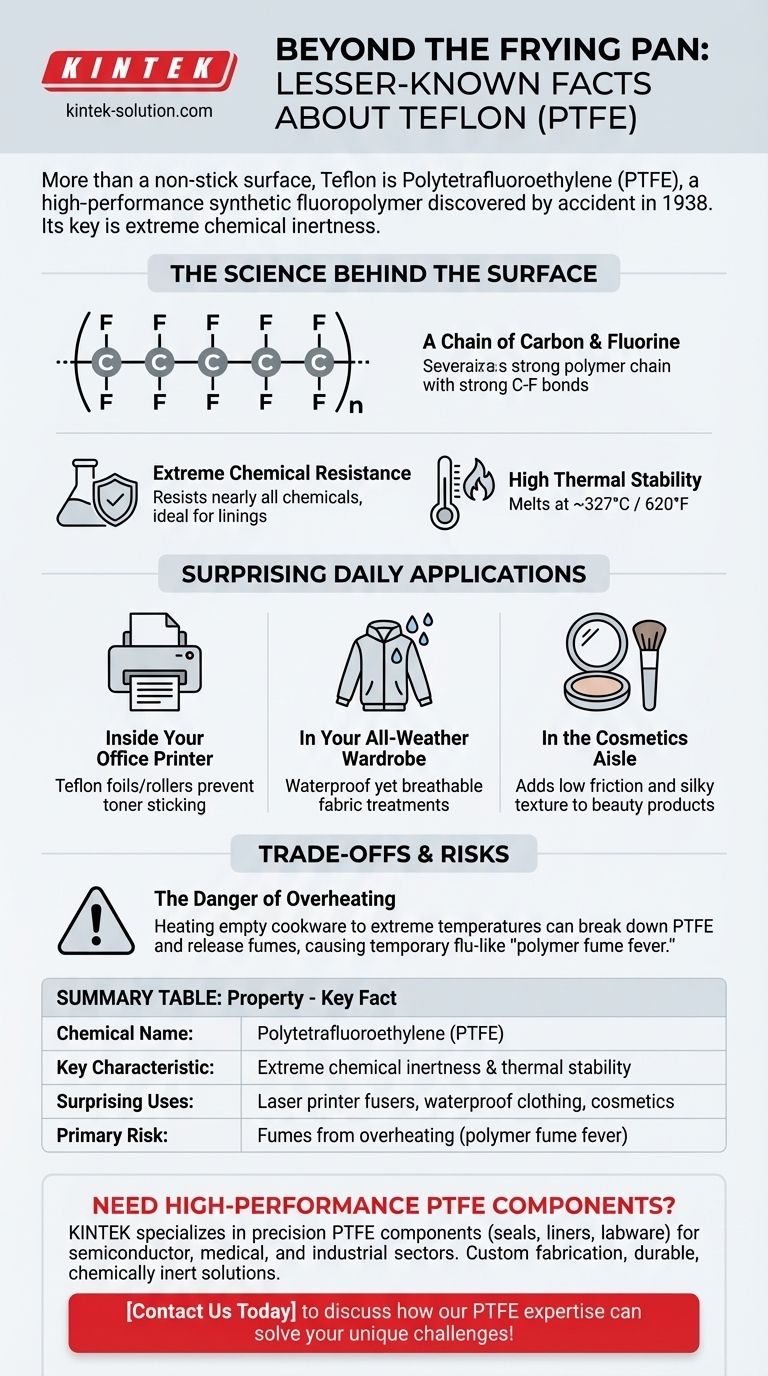

The Science Behind the Slippery Surface

To understand Teflon's diverse roles, you must first understand its fundamental chemistry. It is not merely a coating; it is a unique polymer with a specific and remarkably stable structure.

A Chain of Carbon and Fluorine

Teflon's chemical name is Polytetrafluoroethylene (PTFE). Its structure is a long, repeating chain of carbon and fluorine atoms, represented by the formula (C2F4)n.

The bond between carbon and fluorine is one of the strongest known in organic chemistry. This molecular structure is the source of Teflon's strength, toughness, and flexibility across a wide range of temperatures.

Extreme Chemical Resistance

PTFE is one of the most chemically non-reactive substances known. It resists corrosion and breakdown from nearly all chemicals.

In fact, its chemical resistance is so profound that only a few substances, like highly reactive alkali metals, are capable of compromising its structure. This makes it invaluable for lining pipes and containers in the chemical industry.

High Thermal Stability

Teflon performs reliably across an exceptional temperature range. It melts at approximately 600 K (327°C / 620°F), allowing it to handle the heat of cooking.

This thermal stability is also critical for its industrial applications, where it must withstand extreme operating conditions without degrading.

Surprising Applications You Encounter Daily

While cookware made Teflon a household name, its most critical applications are often hidden in plain sight, enabling the function of technology we use every day.

Inside Your Office Printer

Many laser printers use Teflon foils or rollers within their fuser assemblies.

As paper passes through the fuser, toner is melted and pressed onto the page. Teflon's heat resistance and non-stick properties are essential to ensure a clean transfer without the toner sticking to the roller itself.

In Your All-Weather Wardrobe

The textile industry utilizes Teflon to create waterproof yet breathable fabrics.

By treating fabrics with a thin layer of the material, manufacturers can create a barrier that repels liquid water from the outside while still allowing water vapor (sweat) to escape from the inside.

In the Cosmetics Aisle

Some beauty products, such as foundations or powders, incorporate Teflon for its textural properties.

Its inherent low friction and slipperiness help these products glide on smoothly and can contribute to a silky, soft-focus finish on the skin.

Understanding the Trade-offs and Risks

Like any material, the benefits of Teflon are accompanied by specific limitations and safety considerations that are important to understand objectively.

The Danger of Overheating

The primary health concern associated with Teflon-coated cookware involves extreme overheating.

If a pan is heated to a very high temperature while empty, the PTFE coating can begin to break down and release fumes.

Polymer Fume Fever

Inhaling these fumes can lead to a temporary, flu-like condition known as polymer fume fever.

Symptoms can include fever, sore throat, coughing, and general discomfort. This underscores the importance of never leaving non-stick cookware unattended on a high-heat burner.

Making the Right Choice for Your Goal

Understanding Teflon's properties allows you to correctly assess its role, whether in the kitchen or in a high-tech lab.

- If you are a home cook: Recognize that the primary risk comes from overheating empty cookware, not from normal use at proper cooking temperatures.

- If you are an engineer or designer: Appreciate Teflon (PTFE) for its extreme chemical inertness and thermal stability, making it a powerful problem-solver for harsh environments.

- If you are simply curious: View Teflon not as a kitchen gadget material, but as a high-performance polymer whose unique properties are critical to modern technology.

Understanding Teflon as a specialized material empowers you to use it safely and appreciate its widespread impact.

Summary Table:

| Property | Key Fact |

|---|---|

| Chemical Name | Polytetrafluoroethylene (PTFE) |

| Key Characteristic | Extreme chemical inertness and thermal stability |

| Surprising Uses | Laser printer fusers, waterproof clothing, cosmetics |

| Primary Risk | Fumes from overheating (polymer fume fever) |

Need high-performance PTFE components for your demanding applications?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get durable, chemically inert solutions tailored to your specific needs.

Contact us today to discuss how our PTFE expertise can solve your unique challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability