At its core, expanded Polytetrafluoroethylene (ePTFE) is a high-performance material prized for its unique combination of properties. Its industrial applications span a wide range of demanding sectors, including critical sealing in chemical and oil & gas pipelines, advanced filtration systems, electronic insulation, and biocompatible medical devices.

The true value of ePTFE lies not in a single feature, but in the synergy of its microporous structure, extreme chemical inertness, and wide temperature tolerance. This makes it an indispensable problem-solver for environments where conventional materials would quickly fail.

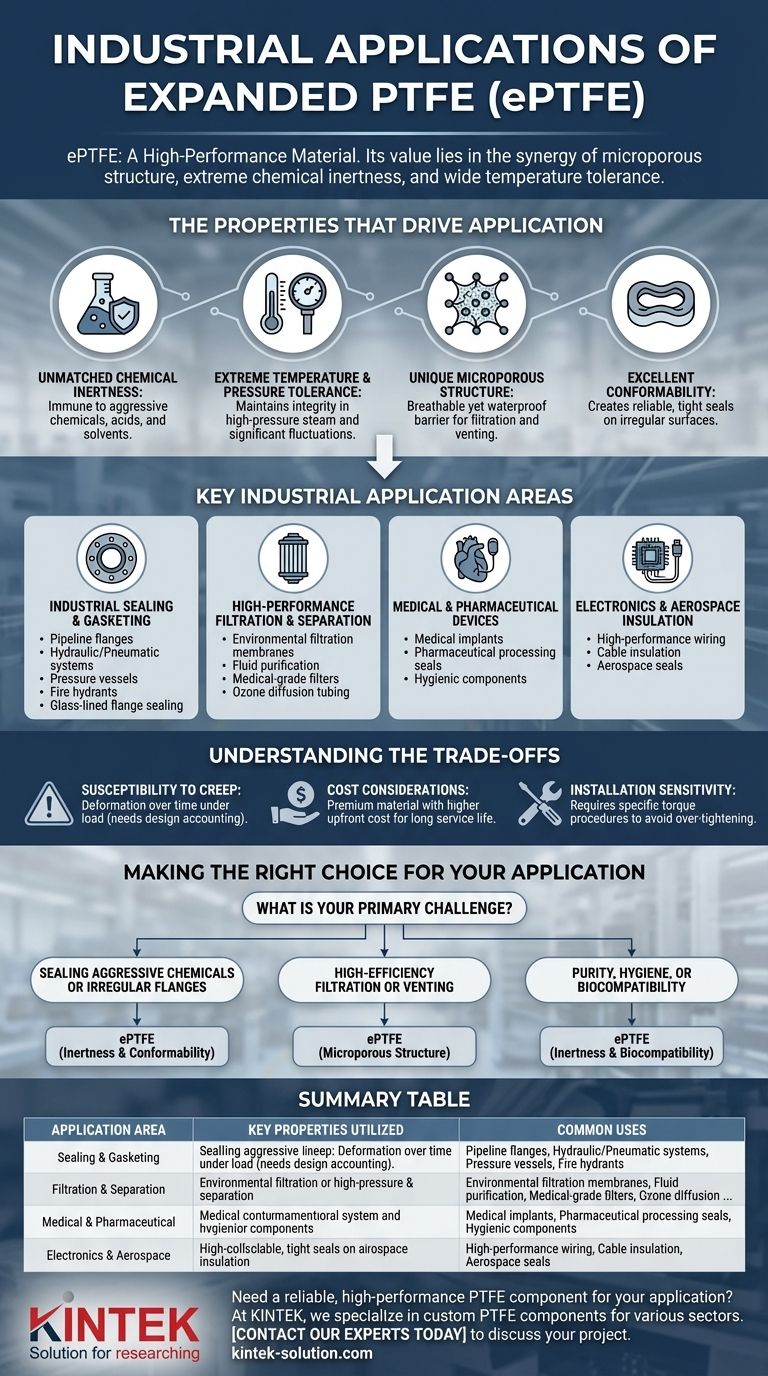

The Properties That Drive Application

Before examining specific uses, it's crucial to understand why ePTFE is so versatile. Its performance stems from a few fundamental characteristics that are engineered during its manufacturing process.

Unmatched Chemical Inertness

ePTFE inherits the chemical resistance of standard PTFE. It is virtually immune to attack from aggressive chemicals, acids, and solvents, making it ideal for use in chemical processing plants and hostile oil and gas operations.

Extreme Temperature and Pressure Tolerance

The material maintains its integrity across a vast temperature range and can withstand high-pressure conditions. This stability is critical for applications like power plant expansion joints, which handle high-pressure steam and significant temperature fluctuations.

A Unique Microporous Structure

The "expansion" process creates a structure of nodes interconnected by fibrils, resulting in a material that is both porous and strong. This allows it to function as a breathable yet waterproof barrier, a key attribute for advanced filters and venting applications.

Excellent Conformability

In forms like gaskets and tapes, ePTFE is soft and conforms easily to irregular or damaged surfaces under compression. This creates a reliable, tight seal even on flanges that are not perfectly flat, preventing leaks in critical systems.

Key Industrial Application Areas

These core properties translate directly into solutions for some of the toughest industrial challenges across various sectors.

Industrial Sealing and Gasketing

This is arguably the most common application for ePTFE. Its ability to seal aggressive chemicals and conform to imperfect surfaces makes it a go-to material for gaskets, tapes, and joint sealants.

You will find it sealing flange joints in pipelines, hydraulic and pneumatic systems, fire hydrants, and pressure vessels. It is especially effective for sealing delicate plastic or glass-lined flanges that cannot withstand the high bolt loads required for other gasket types.

High-Performance Filtration and Separation

The microporous nature of ePTFE makes it a superior material for filtration. It can be engineered to allow gases to pass through while blocking liquids, or to filter out microscopic particulates from a fluid stream.

Common uses include environmental filtration membranes, fluid purification systems, and medical-grade filters. For example, ePTFE tubing is used to diffuse ozone gas into iron-rich water for purification without degrading the tubing itself.

Medical and Pharmaceutical Devices

Because ePTFE is chemically inert and biocompatible, it is widely used in the medical field for implants and other devices that come into contact with the human body.

In pharmaceutical manufacturing, its purity and resistance to harsh cleaning chemicals make it suitable for expansion joints and seals in processing equipment, ensuring product integrity and meeting strict hygiene standards.

Electronics and Aerospace Insulation

The excellent dielectric properties of ePTFE, combined with its resistance to high temperatures, make it a valuable electronic insulator for high-performance wiring and cables.

In aerospace, its light weight and reliability under extreme conditions make it a choice material for high-performance seals and insulation components.

Understanding the Trade-offs

No material is perfect, and choosing ePTFE requires an awareness of its limitations. Being objective about these factors is key to successful implementation.

Susceptibility to Creep

Like all PTFE-based materials, ePTFE can be susceptible to "creep," which is the tendency to slowly deform over time under a constant load. This must be accounted for in the design of long-term, high-pressure static seals.

Cost Considerations

ePTFE is a premium, high-performance polymer. Its manufacturing process is more complex than that of standard elastomers or commodity plastics, making it a more expensive option upfront. Its cost is justified by its long service life and reliability in critical applications.

Installation Sensitivity

The softness that makes ePTFE an excellent gasket material also means it can be damaged by over-tightening. Proper installation requires following specific torque procedures to achieve an effective seal without crushing the material.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is sealing aggressive chemicals or irregular flanges: ePTFE's chemical inertness and conformability make it the ideal choice, especially in tape or gasket form for quick field repairs.

- If your primary focus is high-efficiency filtration or venting: The material's engineered microporous structure offers precise control over what can pass through, making it perfect for advanced separation tasks.

- If your primary focus is purity, hygiene, or biocompatibility: ePTFE is a proven solution in medical, food, and pharmaceutical applications where material inertness is non-negotiable.

Ultimately, understanding ePTFE's core properties is the key to leveraging its unique capabilities to solve your most demanding engineering challenges.

Summary Table:

| Application Area | Key Properties Utilized | Common Uses |

|---|---|---|

| Sealing & Gasketing | Chemical inertness, conformability | Pipeline flanges, hydraulic systems, pressure vessels |

| Filtration & Separation | Microporous structure | Environmental membranes, fluid purification, medical filters |

| Medical & Pharmaceutical | Biocompatibility, chemical resistance | Implants, process equipment seals, hygienic components |

| Electronics & Aerospace | Dielectric strength, temperature resistance | High-performance wiring, cable insulation, aerospace seals |

Need a reliable, high-performance PTFE component for your application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or high-volume production, our expertise ensures a solution that meets your exact specifications for chemical resistance, temperature stability, and purity.

Contact our experts today to discuss how we can support your project with custom-fabricated PTFE parts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments