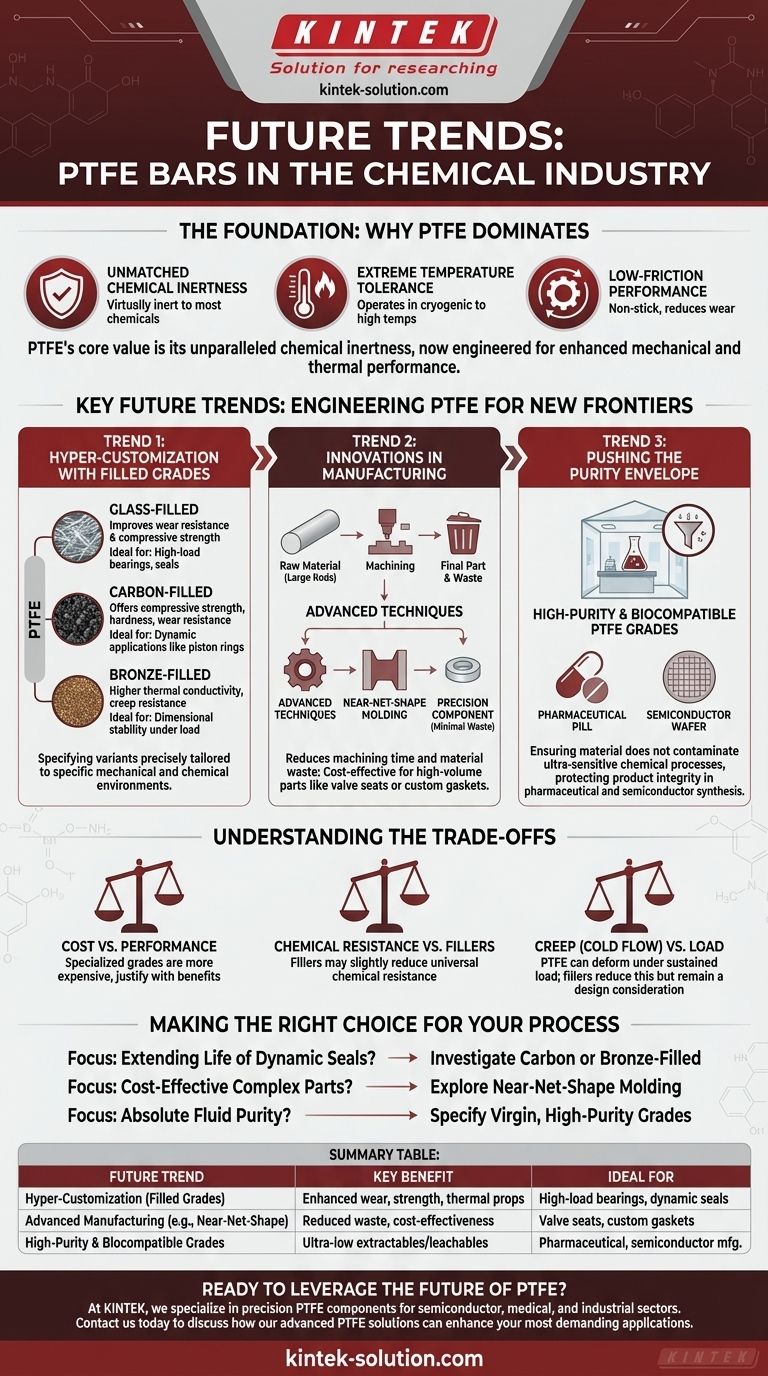

Looking forward, the application of PTFE bars in the chemical industry is evolving beyond their standard use. The most significant future trends are the proliferation of highly customized and filled PTFE grades for specific performance needs, innovations in manufacturing techniques to create more complex and efficient components, and a push toward higher-purity materials for sensitive processes.

The core value of PTFE—its unparalleled chemical inertness—remains its foundation. The future, however, is not about changing this property but about enhancing its mechanical and thermal performance through advanced composites and manufacturing, transforming it from a general-purpose material into a precisely engineered solution for increasingly extreme environments.

The Foundation: Why PTFE Dominates in Chemical Processing

Before looking to the future, it's crucial to understand why PTFE is the incumbent material. Its dominance rests on a unique combination of properties that make it exceptionally well-suited for handling aggressive substances.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, even at elevated temperatures. This is why it is the default choice for seals, gaskets, and linings in reactors, vessels, and piping systems that handle corrosive acids, bases, and solvents.

Extreme Temperature Tolerance

PTFE maintains its integrity and properties over a wide functional temperature range. This allows it to be used reliably in both cryogenic applications and high-temperature processes without degrading, ensuring operational safety and consistency.

Low-Friction Performance

PTFE has one of the lowest coefficients of friction of any solid material. This "non-stick" quality is essential for components like bearings, bushings, and valve packings, as it reduces wear, prevents seizing, and lowers the energy required for operation.

Key Future Trends: Engineering PTFE for New Frontiers

The chemical industry is constantly pushing the boundaries of temperature, pressure, and chemical aggression. The evolution of PTFE is a direct response to these demands, moving the material into more specialized and high-performance roles.

Trend 1: Hyper-Customization with Filled Grades

The most significant trend is the move away from "one-size-fits-all" virgin PTFE. Material suppliers are increasingly offering PTFE bars blended with fillers to enhance specific mechanical properties.

- Glass-Filled PTFE: Improves wear resistance and compressive strength, making it ideal for high-load bearings and seals.

- Carbon-Filled PTFE: Offers excellent compressive strength, hardness, and wear resistance, often used in dynamic applications like piston rings.

- Bronze-Filled PTFE: Provides higher thermal conductivity and creep resistance, suitable for applications requiring dimensional stability under load.

This trend allows engineers to specify a PTFE variant precisely tailored to a component's mechanical and chemical environment, rather than over-engineering with more expensive materials.

Trend 2: Innovations in Manufacturing and Fabrication

Waste reduction and geometric complexity are driving changes in how PTFE components are made. Instead of just machining parts from large rods, advanced techniques are gaining traction.

Near-net-shape molding allows for the creation of components that are very close to their final dimensions, dramatically reducing the machining time and wasted material. This is especially cost-effective for high-volume parts like valve seats or custom gaskets.

Trend 3: Pushing the Purity Envelope

While standard PTFE is highly pure, certain applications in pharmaceutical chemical synthesis or semiconductor manufacturing demand even lower levels of extractables and leachables.

The development of high-purity and biocompatible PTFE grades is a direct response. This trend ensures that the material itself does not become a source of contamination in ultra-sensitive chemical processes, protecting product integrity and yield.

Understanding the Trade-offs

While these trends offer significant advantages, they are not without compromises. A clear-eyed view of the trade-offs is essential for proper material selection.

The Cost of Specialization

Custom-filled grades and components made with advanced manufacturing techniques are inherently more expensive than standard virgin PTFE. The performance benefits must justify the additional upfront cost.

The Filler Compromise

Adding fillers to enhance mechanical properties can sometimes slightly reduce PTFE's universal chemical resistance. For example, glass-filled PTFE is not recommended for service with strong alkalis or hydrofluoric acid. The filler itself can become a point of chemical attack.

The Challenge of Creep

PTFE, even in its advanced forms, is still susceptible to "creep" or cold flow. Under a sustained load, the material can slowly deform. While fillers reduce this tendency, it remains a fundamental design consideration for any structural or high-pressure sealing application.

Making the Right Choice for Your Process

Your specific operational goal should guide your material specification. Use these trends to solve targeted problems within your facility.

- If your primary focus is extending the life of dynamic seals and bearings: Investigate carbon-filled or bronze-filled PTFE bars for superior wear resistance and dimensional stability.

- If your primary focus is producing complex or high-volume parts cost-effectively: Ask your suppliers about their near-net-shape molding capabilities to reduce material waste and machining costs.

- If your primary focus is maintaining absolute fluid purity for sensitive or high-value chemicals: Specify virgin, high-purity PTFE and ensure your supplier provides certification on extractables.

By understanding these advancements, you can leverage PTFE not just as a reliable staple, but as a strategic tool to enhance performance, safety, and efficiency in your most demanding chemical applications.

Summary Table:

| Future Trend | Key Benefit | Ideal For |

|---|---|---|

| Hyper-Customization (Filled Grades) | Enhanced wear resistance, strength, and thermal properties | High-load bearings, dynamic seals, parts requiring dimensional stability |

| Advanced Manufacturing (e.g., Near-Net-Shape) | Reduced waste, cost-effectiveness for complex/high-volume parts | Valve seats, custom gaskets, complex components |

| High-Purity & Biocompatible Grades | Ultra-low extractables/leachables for sensitive processes | Pharmaceutical, semiconductor, and high-value chemical manufacturing |

Ready to leverage the future of PTFE for your chemical processes?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We can help you navigate these trends, offering custom fabrication from prototypes to high-volume orders to meet your specific performance needs in extreme environments.

Contact us today to discuss how our advanced PTFE solutions can enhance the safety, efficiency, and performance of your most demanding applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance