At its core, Teflon is far more than just a coating for non-stick pans. You most commonly encounter it in the kitchen on frying pans and baking sheets, on the soleplate of clothing irons to prevent sticking, and inside your car as gaskets and seals that reduce friction and wear. These applications are possible because of its uniquely slick, heat-resistant, and chemically stable nature.

The true value of Teflon (PTFE) isn't in any single feature, but in its rare combination of properties: extreme low friction, high heat resistance, and chemical inertness. This combination makes it an essential problem-solving material in applications far beyond the kitchen.

The Properties Behind the Performance

To understand Teflon's wide range of uses, you must first understand its fundamental characteristics. These unique properties are what engineers and designers leverage to solve complex challenges.

Extreme Low Friction

Teflon, or Polytetrafluoroethylene (PTFE), has one of the lowest coefficients of friction of any known solid. This makes it incredibly "slippery."

This property is critical for parts that need to slide against each other with minimal resistance, such as bearings, seals, and gaskets in automotive and industrial machinery.

High-Temperature Stability

Teflon can withstand high temperatures without degrading, a quality essential for applications involving heat.

This is why it's the go-to material for non-stick cookware and why it's used to coat the soleplates of clothing irons. It also allows it to function effectively in hot engine compartments.

Chemical Inertness

Teflon is non-reactive and won't be corroded by most chemicals. It is a highly stable material.

This makes it invaluable for use in medical devices like catheters and tubes, as well as for lining pipes and storage tanks in the chemical processing industry.

Excellent Electrical Insulation

Teflon does not conduct electricity, making it a superb insulator.

This property is why it's used to insulate electrical wires and cables, particularly in high-performance applications like aerospace and electronics where reliability is paramount.

Where You Encounter Teflon Every Day

While many of its most critical applications are hidden inside machines, you rely on Teflon in more ways than you might realize.

In Your Home

The most obvious use is non-stick cookware, which prevents food from sticking and simplifies cleanup. You'll also find it on baking sheets and as a coating on some small appliances.

In Your Car

Teflon is a workhorse in the automotive industry. It's used for gaskets, seals, and bearings to ensure parts move smoothly with minimal wear and tear, contributing to the longevity and efficiency of your vehicle.

In the Food You Buy

On an industrial scale, Teflon sheets are used to line commercial baking trays and conveyor belts. This prevents food from sticking during mass production, ensuring consistency and making equipment easier to clean.

Understanding the Trade-offs

No material is perfect, and understanding the limitations of Teflon is crucial for using it correctly and safely.

Sensitivity to Abrasives

The non-stick coating on cookware is relatively soft and can be scratched or damaged by metal utensils. This is why wood, silicone, or plastic tools are recommended.

High-Temperature Fumes

When heated to extremely high temperatures (well above normal cooking, typically over 500°F or 260°C), Teflon can begin to decompose and release fumes. This is primarily a concern in scenarios of severe overheating, not standard use.

Making the Right Choice

Understanding the "why" behind Teflon's use allows you to appreciate its role in different contexts.

- If your primary focus is cooking: Teflon offers unparalleled non-stick convenience, but always use non-abrasive utensils to protect its surface.

- If your primary focus is engineering or design: Teflon's combination of low friction, heat resistance, and chemical inertness makes it a premier material for solving wear, insulation, and sealing problems.

- If your primary focus is general knowledge: Recognize Teflon as a hidden material whose unique properties make countless modern devices and systems safer, more efficient, and longer-lasting.

From the pan you cook with to the electronics you use, Teflon's unique physics are constantly at work, quietly reducing friction and improving the world around you.

Summary Table:

| Property | Key Benefit | Common Everyday Use |

|---|---|---|

| Extreme Low Friction | Reduces wear and energy loss | Bearings, seals, and gaskets in cars and machinery |

| High-Temperature Stability | Withstands heat without degrading | Non-stick cookware, iron soleplates |

| Chemical Inertness | Resists corrosion from harsh chemicals | Medical tubing, chemical tank linings |

| Excellent Electrical Insulation | Prevents electrical conduction | Insulation for high-performance wires and cables |

Need High-Performance PTFE Components?

Leverage the unique properties of Teflon (PTFE) for your specialized applications. KINTEK manufactures precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We combine precision production with the flexibility to support your project from prototype to high-volume orders.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE solutions can enhance your product's performance and durability.

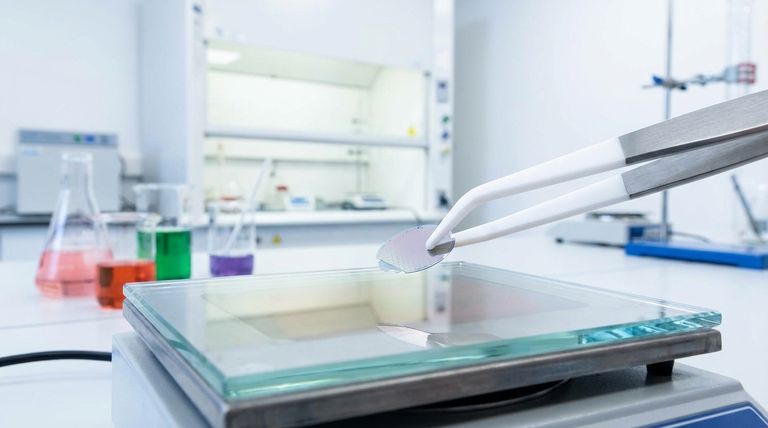

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs