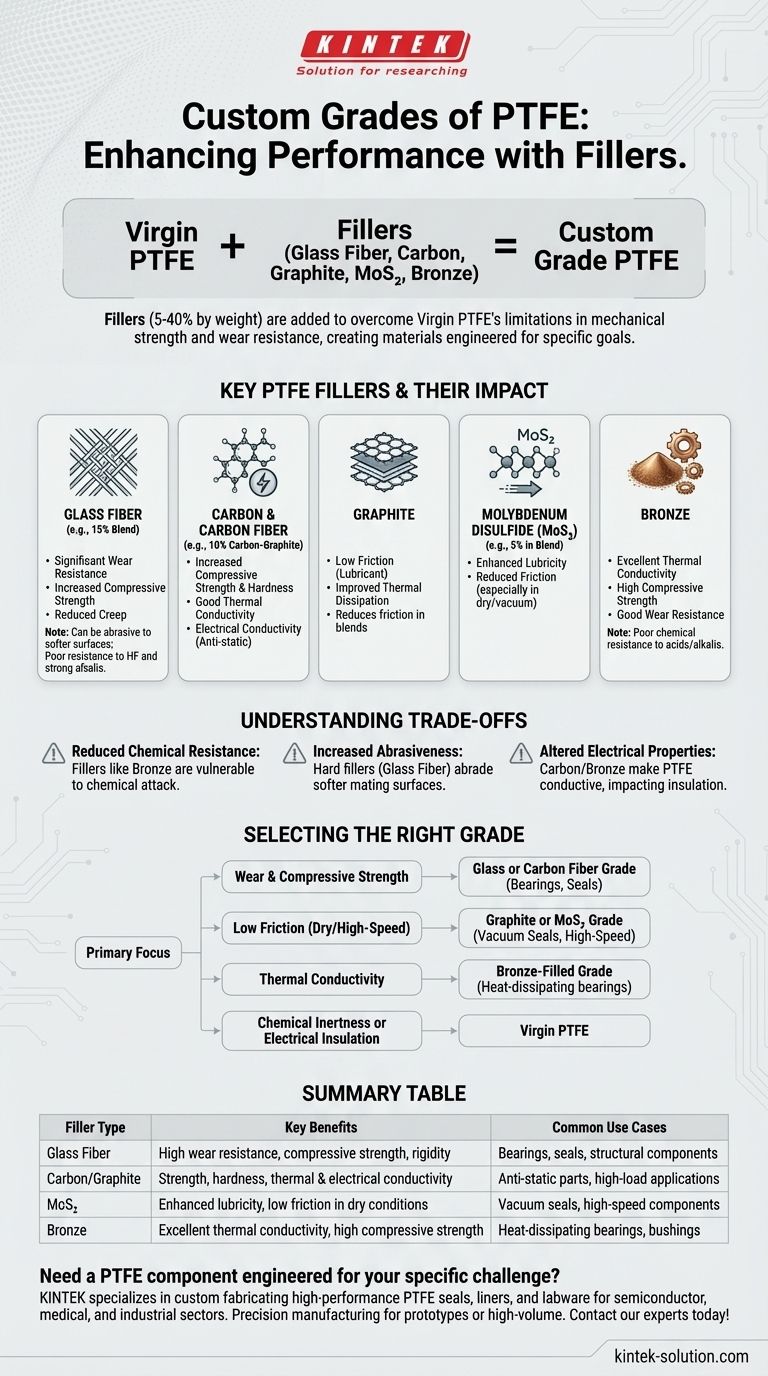

To create custom grades of PTFE, various fillers are added to the virgin material to enhance specific properties. These fillers commonly include glass fiber, carbon, graphite, bronze, and molybdenum disulfide (MoS₂), often in percentages ranging from 5% to 40% by weight. Blended fillers, such as carbon-graphite or glass fiber with MoS₂, are also used to achieve a combination of desired characteristics.

Virgin PTFE is an exceptional material for its chemical inertness and low friction, but it suffers from poor mechanical strength and wear resistance. Fillers are introduced to systematically overcome these limitations, creating a custom material engineered for a specific performance goal.

The Purpose of PTFE Fillers: Moving Beyond Virgin PTFE

Limitations of Virgin PTFE

Virgin, or unfilled, Polytetrafluoroethylene (PTFE) is known for its remarkable properties. It has an extremely low coefficient of friction and is nearly impervious to chemical attack.

However, it has significant mechanical weaknesses. It is susceptible to creep (deformation under load) and has low wear resistance, making it unsuitable for many demanding mechanical applications like bearings or high-load seals.

How Fillers Enhance Performance

Fillers are non-PTFE materials mixed into the base polymer before it is molded. Each type of filler imparts distinct characteristics to the final product.

By adding a filler, you can drastically improve properties like compressive strength, thermal conductivity, and abrasion resistance to meet the demands of a specific operating environment.

Key PTFE Fillers and Their Impact

Each filler offers a unique profile of benefits. The choice and percentage depend entirely on the target application's primary challenge, whether it be load, speed, temperature, or electrical requirements.

Glass Fiber: For Rigidity and Wear Resistance

Glass fiber is the most common filler for PTFE. It significantly improves wear resistance and compressive strength compared to the virgin material.

It also enhances rigidity and reduces creep. However, it can be abrasive to softer mating surfaces and has poor resistance to hydrofluoric acid and strong alkalis. A common blend is 15% glass fiber.

Carbon and Carbon Fiber: For Strength and Conductivity

Adding carbon increases compressive strength and hardness. It provides good thermal conductivity, helping to dissipate heat from wear surfaces.

Crucially, carbon also makes the PTFE electrically conductive, which is ideal for anti-static applications. A common combination is a 10% carbon-graphite blend.

Graphite: For Low Friction and Thermal Dissipation

Graphite is primarily used as a lubricant. It reduces the coefficient of friction, especially in dry-running or high-speed applications.

When combined with other fillers like carbon or glass, it helps lower the friction of those blends while improving thermal dissipation.

Molybdenum Disulfide (MoS₂): For Enhanced Lubricity

Often called "moly," MoS₂ is another lubricant that enhances slip properties and reduces friction. It is particularly effective in vacuum or dry-running applications.

It is often used in smaller percentages (around 5%) alongside another primary filler, such as in a blend of 15% Glass Fiber with 5% Molybdenum Disulfide, to improve surface lubricity without sacrificing mechanical strength.

Bronze: For Thermal Conductivity and Compressive Strength

Bronze powder creates a composite with excellent wear resistance and high thermal conductivity. This makes it ideal for applications where heat needs to be drawn away from a bearing surface.

Bronze-filled PTFE has higher compressive strength than most other grades, but it has poor chemical resistance, particularly to acids and alkalis.

Understanding the Trade-offs of Filled PTFE

Introducing fillers is a targeted engineering decision, not a universal upgrade. Enhancing one property often comes at the expense of another.

Reduced Chemical Resistance

The primary advantage of virgin PTFE is its near-total chemical inertness. Most fillers, especially bronze, do not share this quality and can be attacked by chemicals that would not harm the base polymer.

Increased Abrasiveness

Hard fillers like glass fiber can abrade softer mating surfaces, such as shafts made from aluminum or non-hardened steel. The material selection for both contacting surfaces is critical.

Altered Electrical Properties

While virgin PTFE is an excellent electrical insulator, the addition of carbon or bronze fillers makes the material conductive. This is a benefit for anti-static needs but a failure point if electrical insulation is required.

Selecting the Right PTFE Grade for Your Application

Your choice must be guided by the single most important demand of your application.

- If your primary focus is wear resistance and compressive strength: A glass or carbon fiber-filled grade is the standard choice for bearings, seals, and structural components.

- If your primary focus is low friction in dry or high-speed conditions: A grade filled with graphite or molybdenum disulfide (MoS₂) will provide the necessary lubricity.

- If your primary focus is maximum thermal conductivity: Bronze-filled PTFE is unmatched in its ability to dissipate heat from a wear surface.

- If your primary focus is ultimate chemical inertness or electrical insulation: You must use virgin (unfilled) PTFE and design around its mechanical limitations.

Understanding the role of each filler empowers you to select a PTFE grade engineered for your specific challenge.

Summary Table:

| Filler Type | Key Benefits | Common Use Cases |

|---|---|---|

| Glass Fiber | High wear resistance, compressive strength, rigidity | Bearings, seals, structural components |

| Carbon/Graphite | Strength, hardness, thermal & electrical conductivity | Anti-static parts, high-load applications |

| Molybdenum Disulfide (MoS₂) | Enhanced lubricity, low friction in dry conditions | Vacuum seals, high-speed components |

| Bronze | Excellent thermal conductivity, high compressive strength | Heat-dissipating bearings, bushings |

Need a PTFE component engineered for your specific challenge? KINTEK specializes in custom fabricating high-performance PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Whether you require a prototype or high-volume production, our precision manufacturing ensures your parts meet exact performance demands. Contact our experts today to discuss your project and material requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of using Teflon sheets in heat press machines? Achieve Flawless Transfers & Protect Your Equipment

- What are tips for using PTFE in low-friction applications? Optimize Performance and Durability

- How does PTFE paste extrusion work? A Guide to Manufacturing High-Strength Components

- What are the steps involved in PTFE isostatic pressing? A Guide to Uniform, Complex Parts

- What is a PTFE lined ball valve? A Corrosion-Resistant Solution for Harsh Chemicals

- What are the three most common machining processes for Teflon? Master CNC Turning, Milling & Drilling

- What makes PTFE gaskets an ideal sealing material? Unmatched Chemical & Temperature Resistance

- What are some medical applications of PTFE energized seals? Ensuring Reliability and Purity in Medical Devices