In the chemical sector, Polytetrafluoroethylene (PTFE) is most commonly used for corrosion-proof linings in vessels and tanks, for high-integrity seals and gaskets, and for critical components within pumps and valves. Its unique combination of chemical inertness and thermal stability makes it an essential material for handling aggressive and high-temperature substances safely and reliably.

The core reason PTFE is indispensable in the chemical industry is its near-universal chemical resistance. This single property allows it to protect equipment, prevent dangerous leaks, and ensure product purity in environments where most other materials would quickly fail.

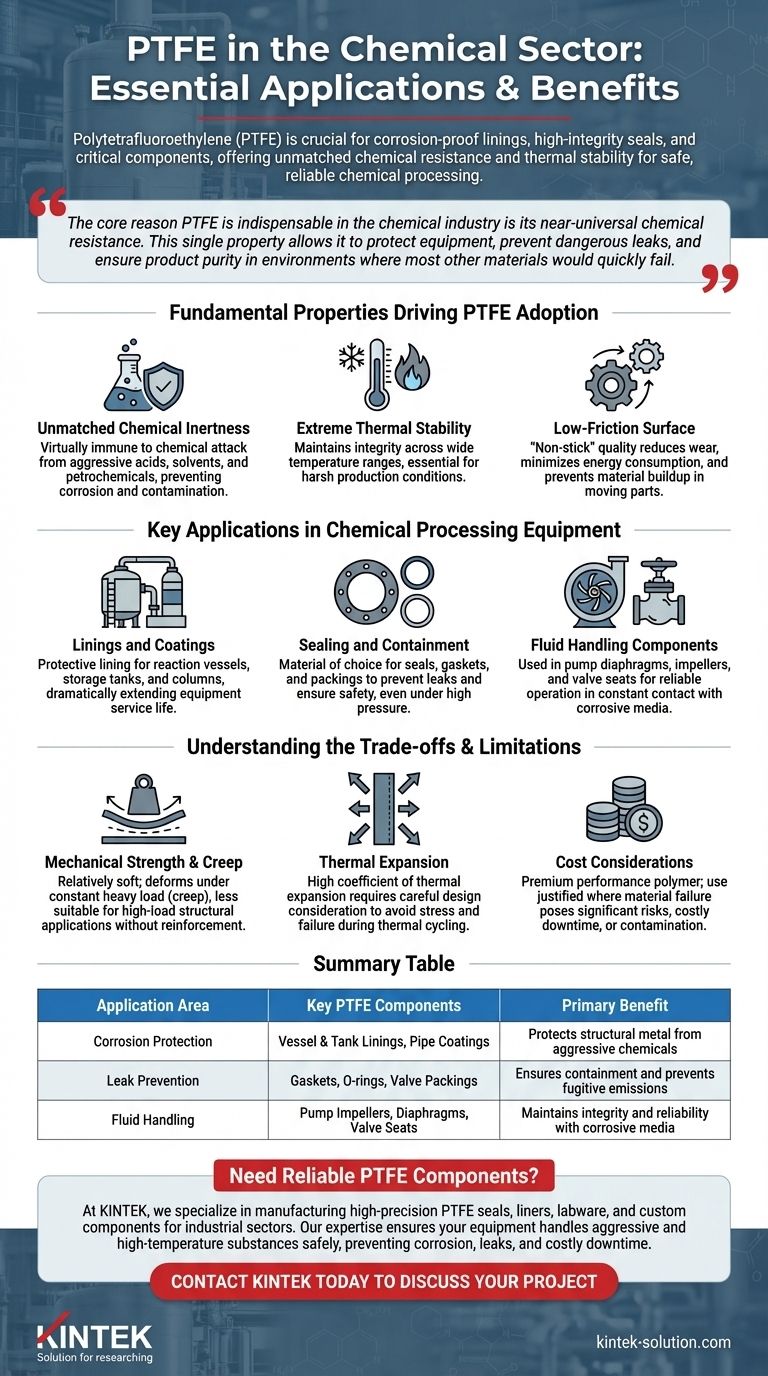

The Fundamental Properties Driving PTFE Adoption

To understand PTFE's role, we must first look at its core characteristics. Its applications are a direct result of a unique combination of material properties that solve critical challenges in chemical processing.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It resists the most aggressive acids, solvents, oxidizing agents, and petrochemicals.

This inertness prevents both the corrosion of equipment and the contamination of the chemical product being processed, which is especially critical in pharmaceutical and food-grade applications.

Extreme Thermal Stability

The material maintains its integrity across a wide temperature range. It does not melt or degrade when handling the high-temperature fluids and reactions common in chemical manufacturing.

This stability is crucial for safety and operational continuity in harsh production conditions, such as inside reaction vessels, autoclaves, and heat exchangers.

Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid. This "non-stick" quality is vital for moving parts.

In applications like bearings, pump impellers, and valve seats, this property reduces wear and tear, minimizes energy consumption, and prevents material buildup that could impede operations.

Key Applications in Chemical Processing Equipment

These fundamental properties translate directly into specific, high-value applications throughout a chemical plant. PTFE is not just one component but a system-wide solution for material integrity.

Linings and Coatings

PTFE is frequently used as a protective lining or coating for large-scale equipment. This includes reaction vessels, storage tanks, columns, and autoclaves.

Applying a PTFE layer protects the underlying structural metal (like steel) from corrosion, dramatically extending the equipment's service life and preventing catastrophic failures.

Sealing and Containment

Preventing leaks is paramount for safety and environmental compliance. PTFE is the material of choice for seals, gaskets, and O-rings in chemical processing.

It is also used for shaft packings in pumps and valves, where it creates a tight seal that prevents aggressive fluids from escaping, even under high pressure.

Fluid Handling Components

Components that are in direct, constant contact with corrosive chemicals rely on PTFE. This includes pump diaphragms, impellers, and the bodies and seats of ball valves.

Using solid or lined PTFE for these parts ensures the fluid handling system can operate reliably without being degraded by the media it transports.

Understanding the Trade-offs and Limitations

While incredibly useful, PTFE is not a universal solution. A trusted advisor must acknowledge its limitations to ensure it is specified correctly.

Mechanical Strength and Creep

PTFE is a relatively soft material compared to metals. Under a constant, heavy load, it can slowly deform over time in a process known as creep.

This makes it unsuitable for certain high-load structural applications unless it is reinforced or used as a component within a more rigid assembly.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes.

Engineers must account for this during design, especially when fitting PTFE liners or seals into metal housings, to avoid stress and failure during thermal cycling.

Cost Considerations

PTFE is a premium performance polymer. Its cost is higher than many standard plastics and commodity metals.

Therefore, its use is typically justified in applications where material failure would lead to significant safety risks, costly downtime, or product contamination.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to your most critical operational need.

- If your primary focus is corrosion prevention: Use PTFE as a liner or coating for large vessels, columns, and pipework to protect capital assets.

- If your primary focus is preventing fugitive emissions: Specify high-quality PTFE gaskets, O-rings, and valve packings to ensure leak-proof containment.

- If your primary focus is equipment reliability: Choose PTFE for internal components like bearings, diaphragms, and impellers that are directly exposed to aggressive media.

Ultimately, leveraging PTFE correctly allows for the safe, efficient, and reliable processing of chemicals that would be impossible with lesser materials.

Summary Table:

| Application Area | Key PTFE Components | Primary Benefit |

|---|---|---|

| Corrosion Protection | Vessel & Tank Linings, Pipe Coatings | Protects structural metal from aggressive chemicals |

| Leak Prevention | Gaskets, O-rings, Valve Packings | Ensures containment and prevents fugitive emissions |

| Fluid Handling | Pump Impellers, Diaphragms, Valve Seats | Maintains integrity and reliability with corrosive media |

Need reliable PTFE components for your chemical processing equipment?

At KINTEK, we specialize in manufacturing high-precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment handles aggressive and high-temperature substances safely, preventing corrosion, leaks, and costly downtime.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss your project requirements and enhance the safety and reliability of your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance