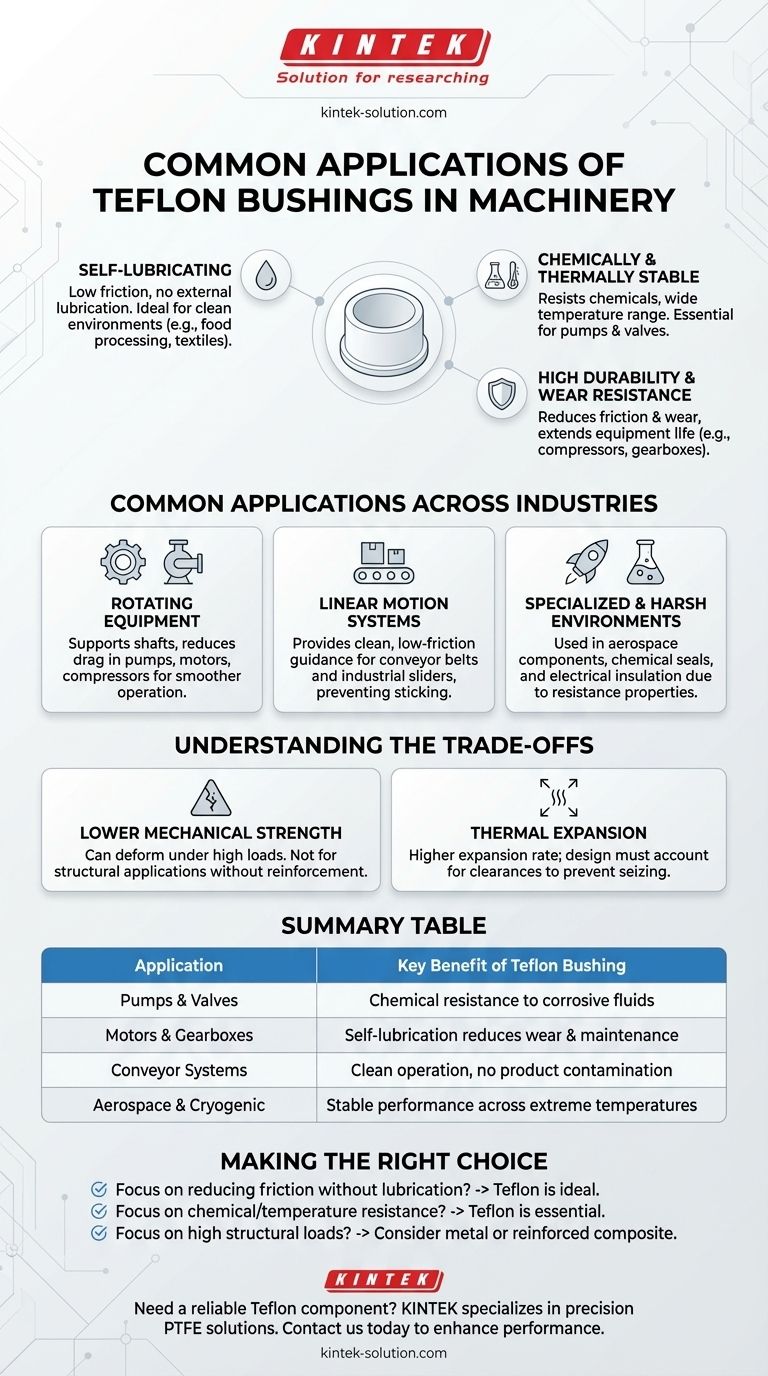

In short, Teflon bushings are commonly used in industrial machinery such as pumps, motors, gearboxes, and conveyor systems. Their primary role is to reduce friction and wear between moving parts, particularly in environments where traditional lubrication is undesirable or impossible.

The core reason Teflon (PTFE) is chosen for these applications is its unique combination of properties: it is self-lubricating, chemically inert, and resistant to extreme temperatures. This makes it an ideal problem-solver for machinery operating in harsh or sensitive conditions.

Why Teflon (PTFE) is a Go-To Material

The effectiveness of a Teflon bushing comes from the fundamental properties of its material, Polytetrafluoroethylene (PTFE). These characteristics directly address common engineering challenges.

The Power of Self-Lubrication

Teflon has one of the lowest coefficients of friction of any solid material. This inherent slipperiness means it can operate smoothly without external lubricants like grease or oil.

This is critical in applications like textile equipment or conveyor systems, where lubricants could contaminate the product. It also reduces maintenance needs significantly.

Exceptional Chemical and Thermal Stability

PTFE is highly resistant to almost all industrial chemicals and solvents. This makes Teflon bushings essential components in pumps and valve guides that handle corrosive fluids.

Furthermore, it maintains its integrity across a wide range of temperatures, ensuring consistent performance in both high-heat and cryogenic environments.

High Durability and Wear Resistance

By providing a low-friction barrier, Teflon bushings reduce the direct contact stress between moving metal components.

This drastically limits wear and tear, extending the operational life of expensive equipment like compressors and gearboxes.

Common Applications Across Industries

Teflon's versatility allows it to be deployed in a wide array of mechanical systems, each leveraging a different aspect of its unique properties.

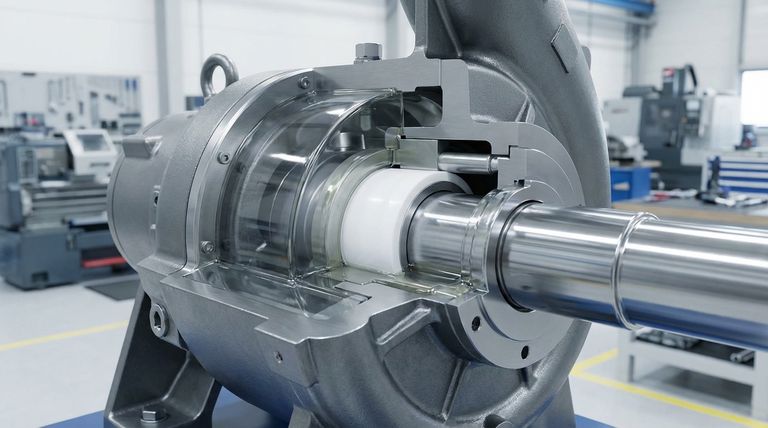

In Rotating Equipment

In machinery like pumps, motors, and compressors, components are in constant rotational motion. Teflon bushings support shafts and reduce the frictional drag that generates heat and consumes energy.

Their reliable performance in these high-demand, continuous-use environments ensures smoother and more efficient operation.

In Linear Motion Systems

Systems such as conveyor belts and industrial sliders require smooth, consistent linear movement.

Teflon bushings provide a clean, low-friction guide that prevents sticking or jerking, which is crucial for manufacturing precision and throughput.

In Specialized and Harsh Environments

Because of its excellent chemical resistance and electrical insulation properties, Teflon is often used in highly specialized equipment.

Applications include aerospace components, seals for chemical processing, and linings in equipment where preventing electrical conductivity is a safety requirement.

Understanding the Trade-offs

While its benefits are significant, Teflon is not a universal solution. It's important to recognize its limitations to use it effectively.

Lower Mechanical Strength

Compared to metal bushings (like bronze or steel), Teflon is a much softer material. It can deform or "creep" under very high static loads.

For this reason, it is not typically used for high-load, structural applications unless it is reinforced with fillers like glass or carbon.

Thermal Expansion

Teflon has a higher coefficient of thermal expansion than most metals. Engineers must account for this in the design, ensuring proper clearances are maintained so the bushing doesn't seize within its housing at high temperatures.

Making the Right Choice for Your Goal

Selecting the correct bushing material depends entirely on the primary challenge you need to solve.

- If your primary focus is reducing friction without lubrication: Teflon is an ideal choice, especially in clean environments like food processing or where maintenance is difficult.

- If your primary focus is chemical or temperature resistance: Teflon's inert nature makes it essential for pumps, valves, and equipment handling corrosive or extreme-temperature substances.

- If your primary focus is handling high structural loads: You should consider a metal-backed bushing, a reinforced PTFE composite, or a different material like bronze or hardened steel.

Ultimately, understanding these core properties allows you to deploy Teflon bushings precisely where they deliver maximum value: in demanding environments where other materials would fail.

Summary Table:

| Application | Key Benefit of Teflon Bushing |

|---|---|

| Pumps & Valves | Chemical resistance to corrosive fluids |

| Motors & Gearboxes | Self-lubrication reduces wear & maintenance |

| Conveyor Systems | Clean operation, no product contamination |

| Aerospace & Cryogenic | Stable performance across extreme temperatures |

Need a reliable, high-performance Teflon component for your machinery?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom bushings, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates smoothly in the most demanding conditions, reducing downtime and maintenance costs.

Whether you need a prototype or a high-volume order, we deliver solutions tailored to your exact specifications. Contact us today to discuss how our Teflon components can enhance your machinery's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications