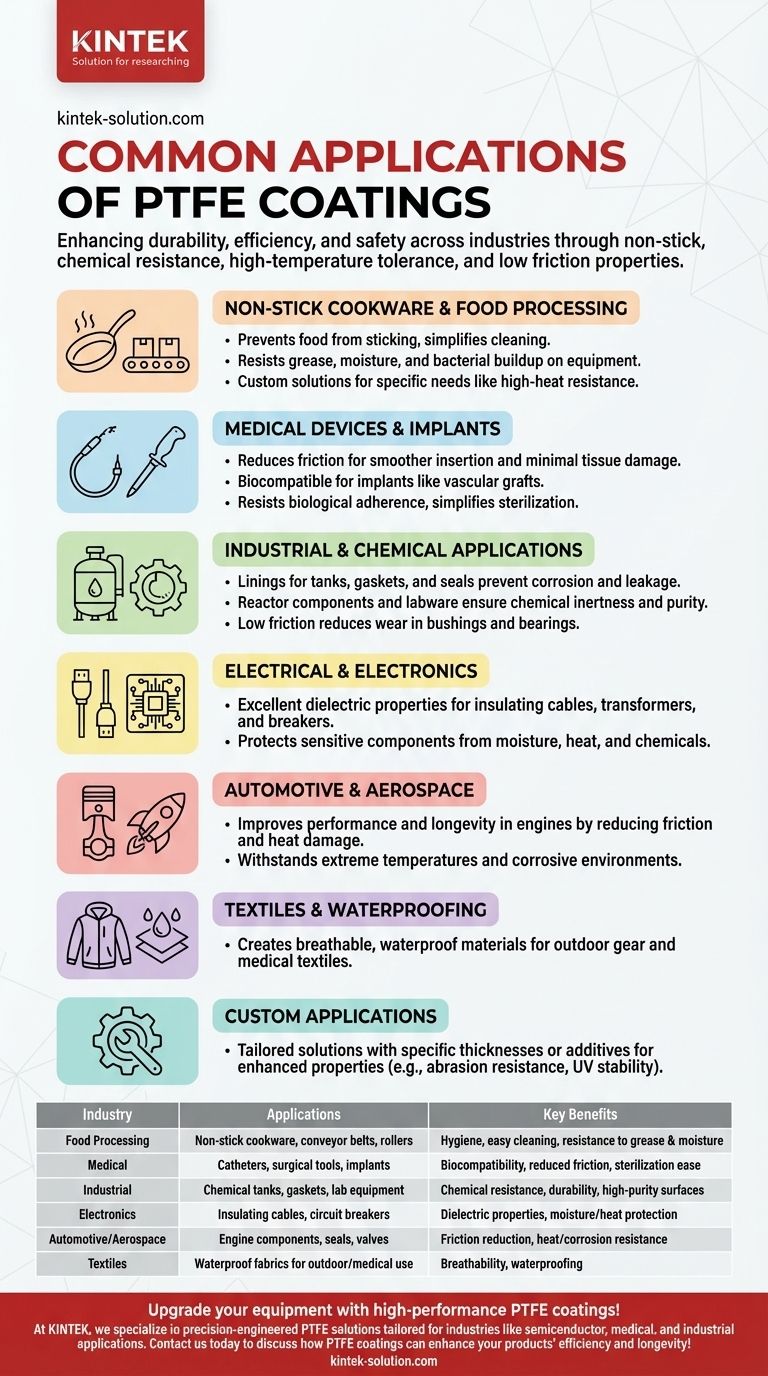

PTFE (Polytetrafluoroethylene) coatings are widely used across multiple industries due to their exceptional properties, including non-stick characteristics, chemical resistance, high-temperature tolerance, and low friction. These coatings enhance durability, efficiency, and safety in applications ranging from household cookware to advanced medical devices and industrial machinery. Their versatility makes them indispensable in environments where performance under harsh conditions is critical.

Key Points Explained:

-

Non-Stick Cookware and Food Processing Equipment

- PTFE coatings are most famously used in non-stick cookware, such as frying pans and bakeware, due to their ability to prevent food from sticking and simplify cleaning.

- In food processing, PTFE-coated conveyor belts, rollers, and equipment surfaces resist grease, moisture, and bacterial buildup, ensuring hygiene and operational efficiency.

- Example: (custom ptfe)[/topic/custom-ptfe] coatings can be tailored for specific food industry needs, such as high-heat resistance or enhanced non-stick performance.

-

Medical Devices and Implants

- PTFE coatings are used in catheters, guidewires, and surgical instruments to reduce friction, enabling smoother insertion and minimizing tissue damage.

- Implantable devices like vascular grafts benefit from PTFE’s biocompatibility and resistance to bodily fluids.

- Surgical tools coated with PTFE resist biological material adherence, simplifying sterilization and reducing infection risks.

-

Industrial and Chemical Applications

- PTFE linings for tanks, gaskets, and seals in chemical plants prevent corrosion and leakage when handling aggressive substances.

- Reactor components and lab equipment (e.g., PTFE bottles) use PTFE coatings for chemical inertness and high-purity requirements.

- Machinery parts like bushings and bearings leverage PTFE’s low friction to reduce wear and energy consumption.

-

Electrical and Electronics

- PTFE’s excellent dielectric properties make it ideal for insulating cables, transformers, and circuit breakers.

- It protects sensitive electronic components from moisture, heat, and chemical exposure.

-

Automotive and Aerospace

- PTFE-coated pistons, valves, and seals improve performance and longevity in engines by reducing friction and heat damage.

- Aerospace components use PTFE coatings to withstand extreme temperatures and corrosive environments.

-

Textiles and Waterproofing

- PTFE-coated fabrics create breathable, waterproof materials for outdoor gear and medical textiles.

-

Custom Applications

- Industries often require tailored PTFE solutions, such as coatings with specific thicknesses or additives for enhanced properties like abrasion resistance or UV stability.

PTFE coatings continue to evolve, meeting the demands of modern technology while maintaining their reputation for reliability. Have you considered how these coatings might solve challenges in your specific field? Their adaptability ensures they remain a cornerstone of innovation across sectors.

Summary Table:

| Industry | Applications | Key Benefits |

|---|---|---|

| Food Processing | Non-stick cookware, conveyor belts, rollers | Hygiene, easy cleaning, resistance to grease and moisture |

| Medical | Catheters, surgical tools, implants | Biocompatibility, reduced friction, sterilization ease |

| Industrial | Chemical tanks, gaskets, lab equipment | Chemical resistance, durability, high-purity surfaces |

| Electronics | Insulating cables, circuit breakers | Dielectric properties, moisture/heat protection |

| Automotive/Aerospace | Engine components, seals, valves | Friction reduction, heat/corrosion resistance |

| Textiles | Waterproof fabrics for outdoor/medical use | Breathability, waterproofing |

Upgrade your equipment with high-performance PTFE coatings!

At KINTEK, we specialize in precision-engineered PTFE solutions tailored for industries like semiconductor, medical, and industrial applications. Whether you need standard coatings or custom-fabricated components (seals, liners, labware, etc.), our expertise ensures reliability under the toughest conditions.

Contact us today to discuss how PTFE coatings can enhance your products' efficiency and longevity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications