In short, Teflon encapsulated O-rings are used in demanding industrial applications where standard elastomeric seals would fail. Their most common uses are in chemical processing, pharmaceutical and medical manufacturing, semiconductor fabrication, and aerospace systems due to their unique combination of chemical inertness and reliable sealing force.

The core reason for using a Teflon encapsulated O-ring is to gain the extreme chemical and temperature resistance of a solid Teflon ring while retaining the flexibility and compression of a standard rubber O-ring. It offers a "best of both worlds" solution for aggressive environments.

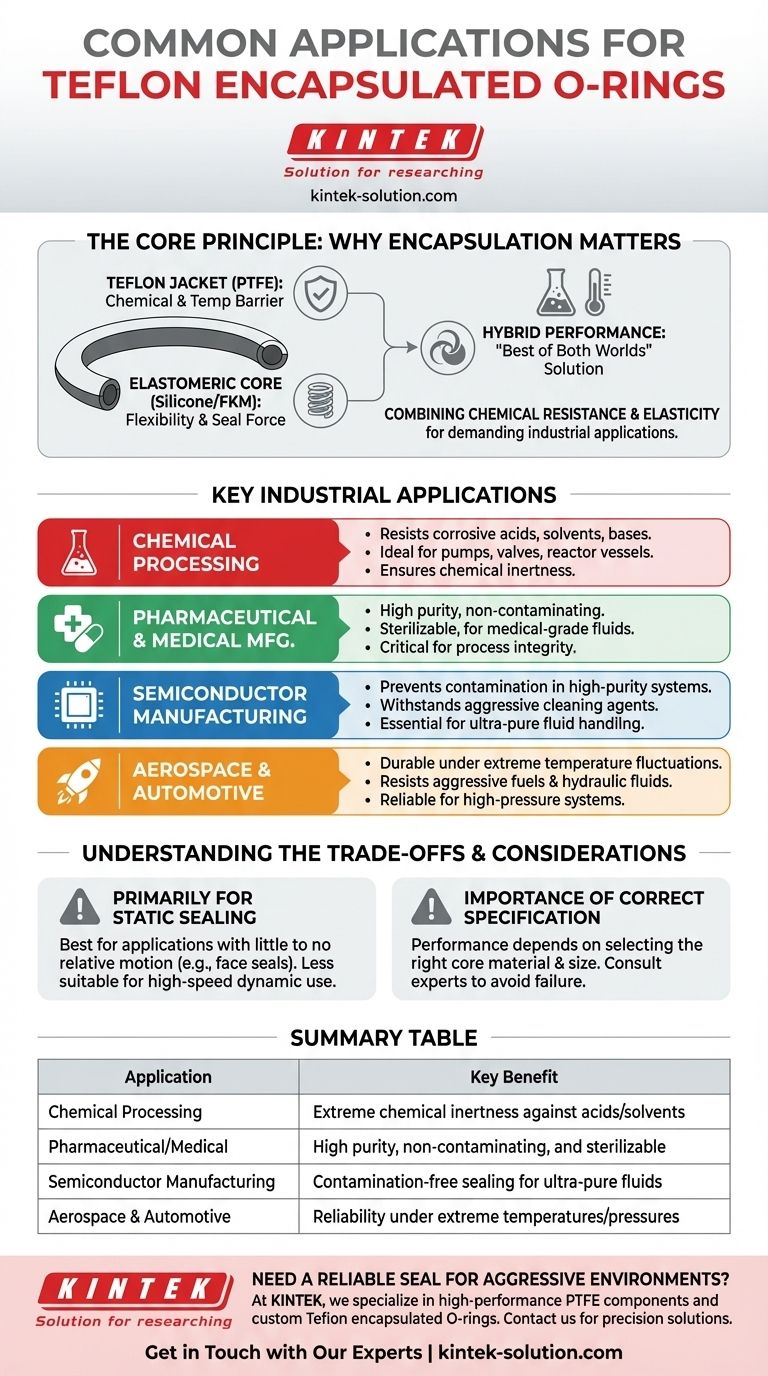

The Core Principle: Why Encapsulation Matters

To understand the applications, you must first understand the design. A standard O-ring is a single material, while an encapsulated O-ring is a composite structure.

Combining Chemical Resistance and Elasticity

A Teflon encapsulated O-ring features an outer jacket made of PTFE (Teflon) that completely encloses a flexible, elastomeric core, typically made of silicone or FKM (Viton).

The Teflon jacket provides a nearly universal barrier against aggressive chemicals and can withstand extreme temperatures.

The inner elastomeric core provides the flexibility and "memory" needed to create and maintain a tight, reliable seal under compression.

Protecting the Core Material

The encapsulated design shields the vulnerable inner core from direct contact with harsh media.

This protection dramatically extends the O-ring's service life in environments that would rapidly degrade a standard elastomer, preventing costly leaks and downtime.

Providing a Reliable Static Seal

These O-rings are primarily engineered for static sealing applications, both axial (face seals) and radial.

While they can be used in some slow, short-movement dynamic applications, their strength lies in creating a durable, long-term seal where there is little to no relative motion between parts.

Key Industrial Applications in Detail

The unique hybrid design makes these O-rings essential in specific, high-stakes industries.

Chemical Processing

In chemical plants, O-rings are exposed to a vast range of corrosive acids, solvents, and bases. The chemical inertness of the Teflon jacket makes it an ideal choice for sealing pumps, valves, and reactor vessels.

Pharmaceutical & Medical Manufacturing

Purity is paramount in these fields. Teflon is non-contaminating and can be sterilized, making it suitable for sealing equipment that handles medical-grade fluids, active pharmaceutical ingredients, and high-purity water systems.

Semiconductor Manufacturing

The fabrication of microchips requires exceptionally clean environments and the use of ultra-pure fluids and aggressive cleaning agents. Encapsulated O-rings prevent contamination and withstand the harsh chemicals used in these high-purity fluid handling systems.

Aerospace & Automotive

In aerospace, seals must perform under extreme temperature fluctuations and exposure to aggressive fuels and hydraulic fluids. The durability of Teflon encapsulated O-rings makes them reliable for sealing high-pressure systems and fluid transfer lines.

Understanding the Trade-offs

While highly effective, these O-rings are not a universal solution. Understanding their limitations is critical for proper specification.

Primarily for Static Sealing

The Teflon jacket is much stiffer and has a higher coefficient of friction than a standard elastomer. This makes encapsulated O-rings less suitable for high-speed or continuous dynamic applications, where they can be prone to premature wear.

Importance of Correct Specification

The performance of an encapsulated O-ring is highly dependent on selecting the right core material and size for the specific application's temperature, pressure, and chemical exposure.

An incorrect specification can lead to seal failure. Always consult manufacturer data and industry guidelines to ensure reliability and avoid costly maintenance.

Making the Right Choice for Your Application

Selecting the correct seal is about aligning its properties with your primary operational goal.

- If your primary focus is handling aggressive chemicals: An encapsulated O-ring is one of the most robust sealing options available, preventing chemical attack that would destroy standard seals.

- If your primary focus is ensuring high purity: The non-contaminating Teflon jacket is ideal for pharmaceutical, food and beverage, or semiconductor applications where process integrity is critical.

- If your primary focus is reliable static sealing in extreme temperatures: The combination of a stable Teflon jacket and a thermally resilient core (like silicone) provides a dependable seal across a wide thermal range.

Ultimately, choosing a Teflon encapsulated O-ring is a strategic decision for applications where component failure is not an option.

Summary Table:

| Application | Key Benefit |

|---|---|

| Chemical Processing | Extreme chemical inertness against acids and solvents |

| Pharmaceutical/Medical | High purity, non-contaminating, and sterilizable |

| Semiconductor Manufacturing | Contamination-free sealing for ultra-pure fluids |

| Aerospace & Automotive | Reliability under extreme temperatures and pressures |

Need a reliable seal for aggressive environments?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom Teflon encapsulated O-rings. Our seals are designed for the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact seal you need for your critical application.

Contact us today to discuss your sealing requirements and let our experts provide a solution that enhances your system's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability