In the food processing industry, Polytetrafluoroethylene (PTFE) is most recognized for its use in non-stick coatings on conveyor belts and food-contact sheets. It is also extensively used for critical machinery components like seals, gaskets, and bearings. Its value stems from a unique combination of heat resistance, chemical inertness, and an exceptionally low-friction surface.

The core reason PTFE is so prevalent in food processing is its ability to solve three critical challenges simultaneously: it prevents product from sticking, withstands aggressive cleaning chemicals and high temperatures, and ensures machinery runs reliably with minimal contamination risk.

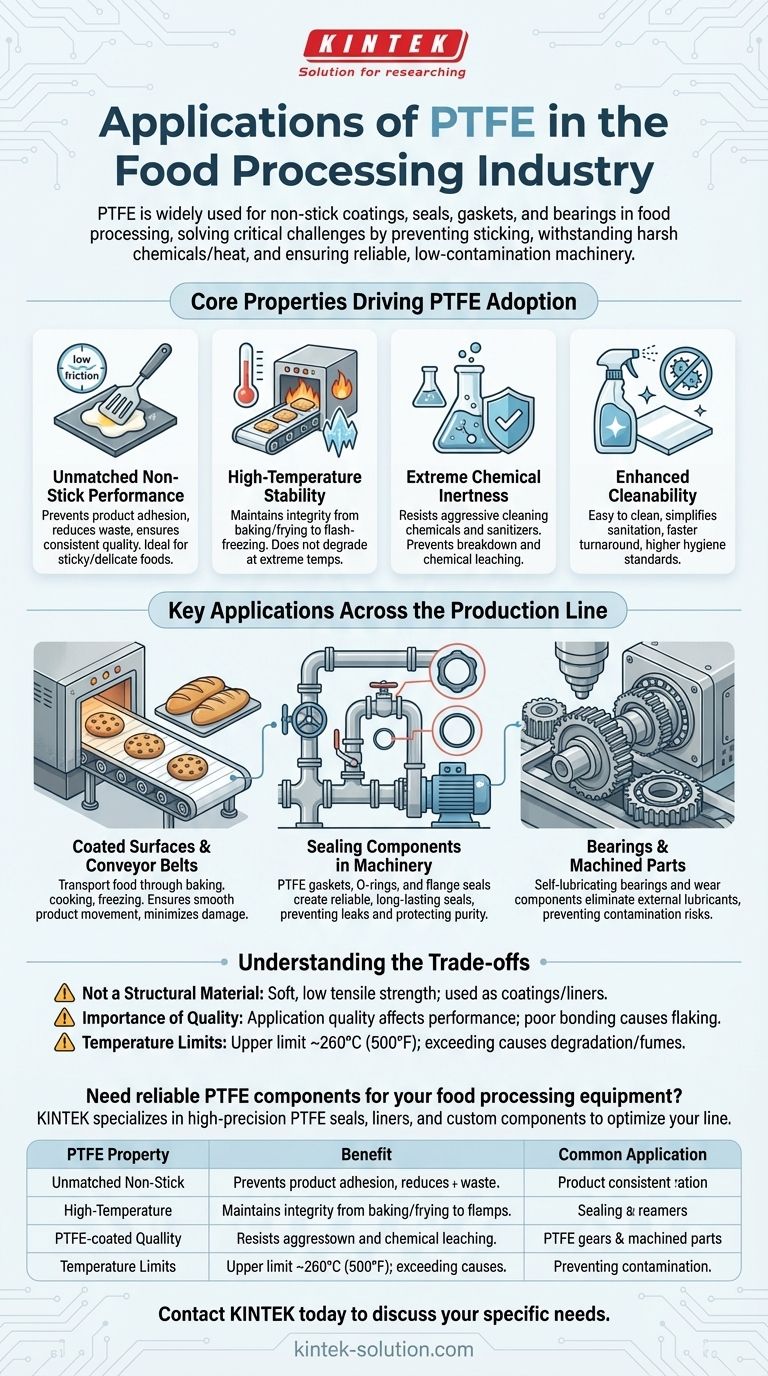

The Core Properties Driving PTFE Adoption

The utility of PTFE in this demanding industry is not accidental. It is a direct result of its fundamental material properties, which are uniquely suited to the challenges of food production.

Unmatched Non-Stick Performance

PTFE has one of the lowest coefficients of friction of any solid material, giving it its famous non-stick quality. This property is crucial for preventing food products—especially sticky or delicate ones like confectionery and baked goods—from adhering to processing surfaces.

This easy release directly reduces product waste and ensures a consistent, high-quality output.

High-Temperature Stability

Food processing often involves extreme temperatures, from baking and frying to flash-freezing. PTFE maintains its structural integrity and non-stick properties across a wide temperature range.

This stability allows it to be used on conveyor belts moving through ovens or other heating elements without degrading or contaminating the food.

Extreme Chemical Inertness

The food industry relies on frequent and aggressive cleaning and sanitation protocols, often involving caustic or acidic chemicals. PTFE is almost entirely inert, meaning it does not react with these chemicals.

This resistance prevents the material from breaking down, ensuring a long service life for components and, most importantly, preventing chemical leaching into the food stream.

Enhanced Cleanability

The combination of being non-stick and chemically inert makes PTFE surfaces exceptionally easy to clean. Food residue and microbes have a difficult time adhering to the surface, simplifying sanitation.

This leads to faster turnaround times between production runs and a higher degree of overall hygiene, a non-negotiable aspect of food safety.

Key Applications Across the Production Line

These core properties translate into several practical applications that improve efficiency and safety throughout a food processing facility.

Coated Surfaces and Conveyor Belts

This is the most visible application. PTFE-coated fabric belts and metal sheets are used to transport food through various stages like baking, cooking, and freezing.

The non-stick surface ensures products move smoothly without damage or loss, which is essential for automated, high-volume production.

Sealing Components in Machinery

Food processing equipment involves complex systems of pipes, valves, and pumps handling everything from liquids to steam.

PTFE is machined into gaskets, O-rings, and flange seals for this equipment. Its chemical resistance and durability create reliable, long-lasting seals that prevent leaks and protect product purity.

Bearings and Machined Parts

In machinery where moving parts are close to the food product, traditional lubricants are a contamination risk.

Because of its low-friction nature, PTFE can be used for bearings and other wear components that require no external lubrication, ensuring the machinery runs smoothly without compromising food safety.

Understanding the Trade-offs

While incredibly versatile, PTFE is not a universal solution. Understanding its limitations is key to using it effectively and safely.

Not a Structural Material

PTFE is a relatively soft material with low tensile strength compared to metals. It is almost always used as a coating, a liner, or a specialized component rather than a primary structural element.

Importance of Quality

The performance of a PTFE coating is highly dependent on the quality of its application. A poorly bonded coating can flake or wear away prematurely, creating a potential contamination risk and negating its benefits.

Temperature Limits Still Exist

While highly heat-resistant, PTFE does have an upper temperature limit (typically around 260°C or 500°F). Exceeding this can cause the material to degrade and release fumes, making temperature control a critical consideration in process design.

Making the Right Choice for Your Goal

Selecting the right PTFE application depends entirely on the problem you are trying to solve within your operation.

- If your primary focus is reducing product waste: Prioritize PTFE-coated conveyor belts and processing sheets for easy and complete product release.

- If your primary focus is improving sanitation: Leverage PTFE's chemical inertness on any surface that requires frequent, harsh cleaning.

- If your primary focus is increasing machinery reliability: Utilize PTFE seals, gaskets, and non-lubricated bearings to minimize leaks, downtime, and maintenance.

Ultimately, integrating PTFE correctly allows food processors to achieve a cleaner, more efficient, and more reliable operation.

Summary Table:

| PTFE Property | Benefit in Food Processing | Common Application |

|---|---|---|

| Non-Stick Surface | Prevents product adhesion, reduces waste | Conveyor belts, processing sheets |

| Chemical Inertness | Withstands harsh sanitizers, prevents contamination | Seals, gaskets, liners |

| High-Temperature Stability | Maintains integrity in cooking/freezing processes | Oven belts, heated surface coatings |

| Low-Friction (Self-Lubricating) | Eliminates need for lubricants near food | Bearings, wear parts |

Need reliable PTFE components for your food processing equipment?

KINTEK specializes in manufacturing high-precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, industrial, and food processing industries. Our expertise ensures your machinery benefits from PTFE's non-stick, chemical-resistant, and high-temperature properties—reducing downtime, enhancing hygiene, and protecting product purity.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability. Let us help you optimize your food processing line with components that meet stringent safety standards.

Contact KINTEK today to discuss your specific needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications