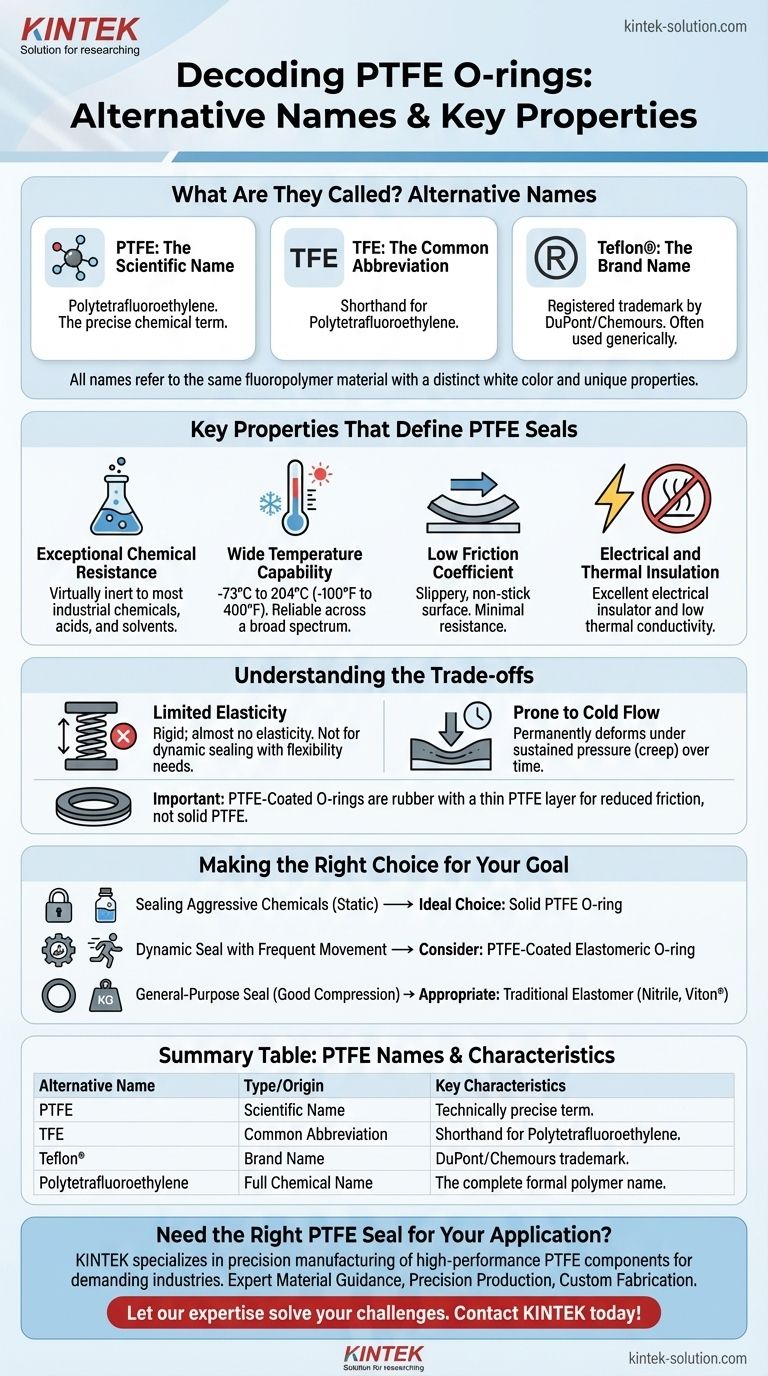

The most common alternative names for PTFE O-rings are Teflon®, TFE, and its full chemical name, Polytetrafluoroethylene. These terms are often used interchangeably in industrial and commercial settings to refer to the same type of seal, which is known for its distinct white color and unique material properties.

The core issue isn't just knowing the names, but understanding that they all refer to a material prized for its extreme chemical resistance and low-friction surface, which dictates its use in very specific, often static, applications.

Decoding the Terminology

While several names exist for this material, they all point back to the same fluoropolymer. Understanding the origin of each term helps clarify any potential confusion when sourcing or specifying parts.

PTFE: The Scientific Name

Polytetrafluoroethylene (PTFE) is the official, chemical name for the material. This is the most technically precise term you will find on engineering datasheets and material specifications.

TFE: The Common Abbreviation

TFE is simply a common abbreviation for Polytetrafluoroethylene. It is frequently used in technical discussions and part descriptions as a shorthand for the full name.

Teflon®: The Brand Name

Teflon® is the registered trademark for PTFE, originally discovered and marketed by DuPont and now owned by Chemours. Much like "Kleenex" is used for tissues, "Teflon" has become a genericized trademark for PTFE in the public mind.

Key Properties That Define PTFE Seals

Regardless of the name used, the material itself has a set of core characteristics that make it suitable for specific demanding environments.

Exceptional Chemical Resistance

PTFE is virtually inert to most industrial chemicals, acids, and solvents. This makes it a primary choice for seals in chemical processing and acid manufacturing plants.

Wide Temperature Capability

These O-rings perform reliably across a broad temperature spectrum, typically from -73°C to 204°C (-100°F to 400°F), without significant degradation.

Low Friction Coefficient

The material has an extremely low coefficient of friction, resulting in a slippery, non-stick surface. This is beneficial in applications where parts must move against the seal with minimal resistance.

Electrical and Thermal Insulation

PTFE is an excellent electrical insulator and has low thermal conductivity, making it valuable in applications where thermal or electrical isolation is required.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Its physical limitations are as important to understand as its strengths.

Limited Elasticity

Unlike rubber or elastomer O-rings, solid PTFE seals are rigid and have almost no elasticity. They do not compress and rebound, making them generally unsuitable for dynamic sealing applications that require flexibility.

Prone to Cold Flow

Under sustained pressure (creep), PTFE can permanently deform over time. This "cold flow" can lead to a loss of sealing force in applications with high, constant loads.

The "PTFE-Coated" Distinction

It is critical to distinguish a solid PTFE O-ring from a PTFE-coated O-ring. The latter is typically a standard rubber O-ring (like Viton® or EPDM) that has a thin layer of PTFE applied to its surface to reduce friction while retaining the flexibility of the rubber core.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching the material's properties to the application's demands.

- If your primary focus is sealing aggressive chemicals in a static application: A solid PTFE O-ring is an ideal choice due to its unmatched chemical inertness.

- If your primary focus is a dynamic seal with frequent movement: You should consider a PTFE-coated elastomeric O-ring to combine the flexibility of rubber with the low friction of a PTFE surface.

- If your primary focus is a general-purpose seal requiring good compression: A traditional elastomer like Nitrile (Buna-N) or Viton® (FKM) is a more appropriate and often more cost-effective solution.

Ultimately, understanding these distinctions ensures you select a seal based on its fundamental material properties, not just its name.

Summary Table:

| Alternative Name | Type/Origin | Key Characteristics |

|---|---|---|

| PTFE | Scientific Name | Technically precise term for the material. |

| TFE | Common Abbreviation | Shorthand for Polytetrafluoroethylene. |

| Teflon® | Brand Name | DuPont/Chemours trademark; often used generically. |

| Polytetrafluoroethylene | Full Chemical Name | The complete, formal name of the polymer. |

Need the Right PTFE Seal for Your Application?

Understanding the terminology is the first step. Selecting the correct PTFE component for your specific chemical, thermal, and mechanical requirements is what ensures success.

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, O-rings, liners, and custom labware. We serve demanding industries like semiconductor, medical, and laboratory where material integrity is non-negotiable.

We deliver value by:

- Expert Material Guidance: Helping you choose between solid PTFE, filled PTFE, or PTFE-coated solutions for optimal performance.

- Precision Production: Manufacturing components that meet exact specifications for critical applications.

- Custom Fabrication: Supporting your projects from initial prototypes to high-volume production runs.

Let our expertise in PTFE solve your sealing challenges. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers