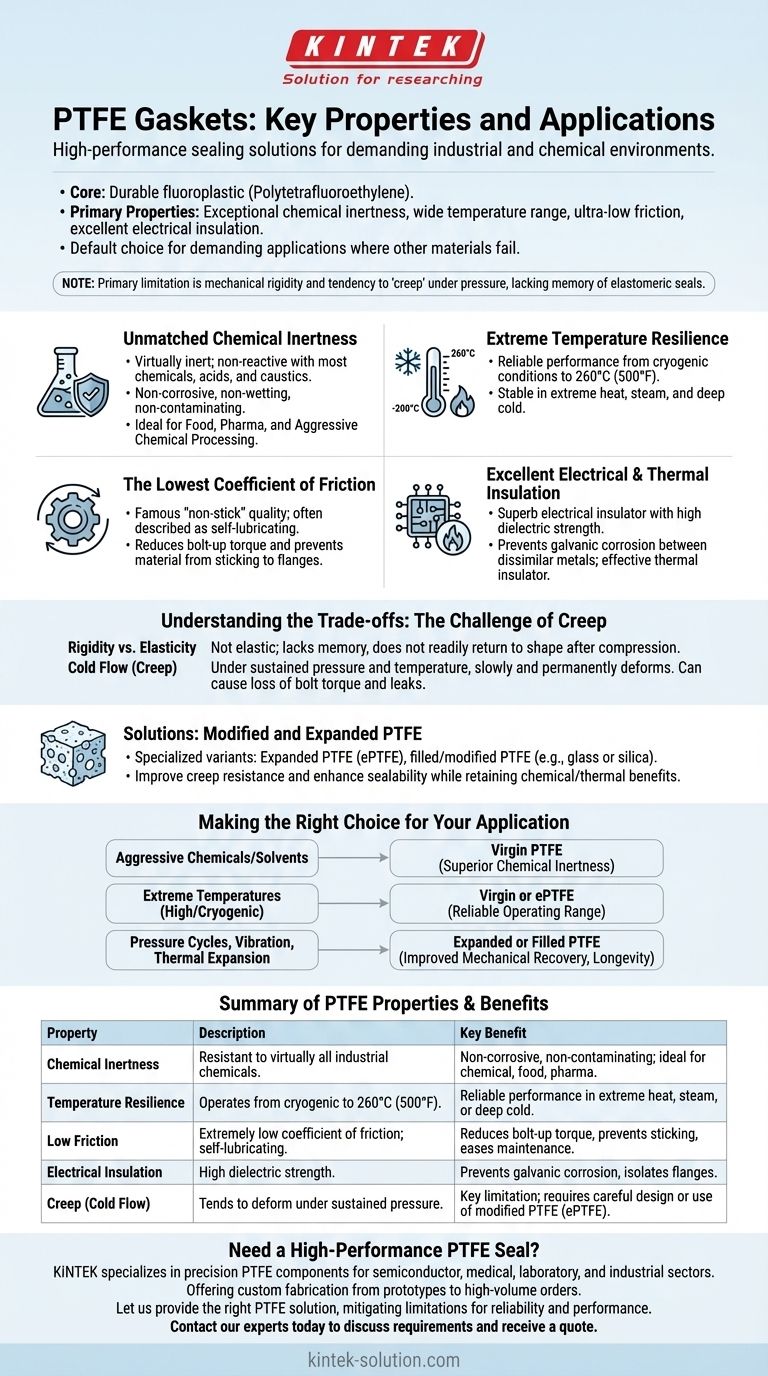

At its core, a PTFE gasket is a high-performance sealing component made from polytetrafluoroethylene, a durable fluoroplastic. Its primary properties are exceptional chemical inertness, a very wide operational temperature range, an extremely low coefficient of friction, and excellent electrical insulation. These characteristics make it a default choice for demanding industrial, mechanical, and chemical applications where other materials would quickly fail.

While PTFE offers near-universal resistance to chemicals and extreme temperatures, its primary limitation is mechanical. Its inherent rigidity and tendency to "creep" under pressure mean it lacks the memory and recovery of elastomeric seals, a critical factor to consider in any design.

The Defining Properties of PTFE Gaskets

To understand where PTFE excels, we must look at its unique combination of thermal, chemical, and physical characteristics. These properties are not just advantages; they define the specific problems that PTFE gaskets are designed to solve.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually inert and will not react with the vast majority of industrial chemicals, acids, and caustics.

This makes it non-corrosive, non-wetting, and non-contaminating, which is critical for applications in the food, pharmaceutical, and aggressive chemical processing industries.

Extreme Temperature Resilience

PTFE gaskets perform reliably across an exceptionally broad temperature spectrum. They maintain their integrity in cryogenic conditions and can operate continuously at temperatures up to 260°C (500°F).

This stability makes them ideal for processes involving extreme heat, steam, or deep cold where typical rubber or elastomer gaskets would become brittle or degrade.

The Lowest Coefficient of Friction

Known for its famous "non-stick" quality, PTFE has one of the lowest coefficients of friction of any solid material. This property is often described as self-lubricating.

In gasket applications, this reduces torque needed during bolt-up and prevents material from sticking to the flange surfaces, simplifying maintenance and removal.

Excellent Electrical and Thermal Insulation

PTFE is a superb electrical insulator with high dielectric strength. This makes it valuable for isolating flanges in piping systems to prevent galvanic corrosion between dissimilar metals. It also serves as an effective thermal insulator.

Understanding the Trade-offs: The Challenge of Creep

No material is perfect, and PTFE's primary strengths are balanced by significant mechanical limitations. Understanding these is crucial for successful implementation.

Rigidity vs. Elasticity

While a sheet of PTFE can be flexible, the material itself is not elastic. Unlike rubber, it does not have "memory" and will not readily return to its original shape after being compressed.

This means it is less forgiving of flange imperfections or vibrations than a more pliable material.

Cold Flow (Creep) and Its Implications

The most significant weakness of standard PTFE is its tendency to exhibit creep, also known as cold flow. Under sustained pressure and temperature, the material will slowly and permanently deform.

This deformation can cause a loss of bolt torque over time, potentially compromising the integrity of the seal and leading to leaks.

Solutions: Modified and Expanded PTFE

To combat the issue of creep, manufacturers have developed specialized variants. Expanded PTFE (ePTFE) and other filled or modified PTFE materials incorporate structures or fillers (like glass or silica) to improve creep resistance and enhance sealability.

These advanced forms offer the chemical and thermal benefits of virgin PTFE while providing better mechanical stability for more demanding service.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's profile to the operational demands. PTFE's unique characteristics make these choices very clear.

- If your primary focus is sealing aggressive chemicals or solvents: Virgin PTFE is almost always the superior choice due to its near-universal chemical inertness.

- If your application involves extreme temperatures (high or cryogenic): PTFE's wide and stable operating range makes it a far more reliable option than most elastomers.

- If your system experiences pressure cycles, vibration, or thermal expansion: Standard PTFE may fail due to creep; specify an expanded or filled PTFE gasket for improved mechanical recovery and seal longevity.

Ultimately, leveraging PTFE's remarkable properties depends on respecting its mechanical limitations and selecting the right type for the job.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to virtually all industrial chemicals, acids, and caustics. | Non-corrosive, non-contaminating; ideal for chemical, food, and pharma industries. |

| Temperature Resilience | Operates from cryogenic to 260°C (500°F). | Reliable performance in extreme heat, steam, or deep cold. |

| Low Friction | Extremely low coefficient of friction; self-lubricating. | Reduces bolt-up torque, prevents sticking, eases maintenance. |

| Electrical Insulation | High dielectric strength. | Prevents galvanic corrosion, isolates flanges. |

| Creep (Cold Flow) | Tends to deform under sustained pressure (key limitation). | Can lead to seal failure; requires careful design or use of modified PTFE (ePTFE). |

Need a High-Performance PTFE Seal for Your Demanding Application?

PTFE gaskets are essential for sealing in extreme chemical, thermal, and electrical environments. Choosing the right type—whether virgin PTFE for ultimate chemical purity or advanced ePTFE for superior creep resistance—is critical to your project's success and longevity.

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, gaskets, liners, and custom labware. We serve the semiconductor, medical, laboratory, and specialized industrial sectors by prioritizing precision production and offering custom fabrication from prototypes to high-volume orders.

Let us provide the right PTFE solution for you. Our expertise ensures you get a seal that leverages PTFE's remarkable properties while mitigating its limitations, delivering reliability and performance.

Contact our experts today to discuss your specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications