In short, PTFE envelope gaskets are used to create a highly effective seal in applications that demand extreme chemical resistance, especially when sealing delicate flange surfaces like glass-lined steel or plastic. They achieve this by combining a soft, compressible core material with a protective outer "envelope" of chemically inert PTFE.

The core problem that PTFE envelope gaskets solve is the need for a seal that is both mechanically compliant and chemically inert. They offer the near-universal chemical resistance of solid PTFE without sacrificing the compressibility required to seal imperfect or fragile flanges effectively.

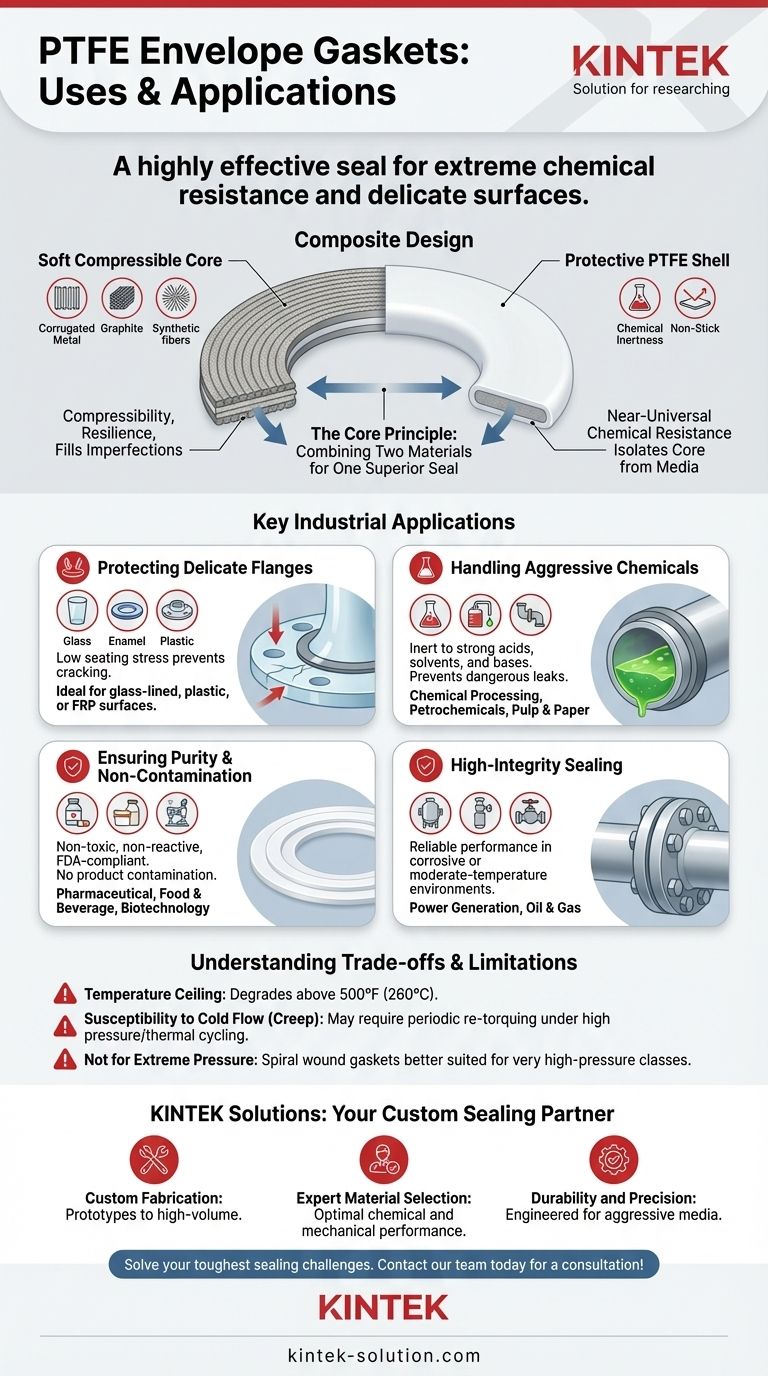

The Core Principle: Combining Two Materials for One Superior Seal

To understand their applications, you must first understand their unique construction. A PTFE envelope gasket is a composite gasket, not a single material.

What is an "Envelope" Gasket?

An envelope gasket consists of two primary components: an inner core material and an outer PTFE shell.

The core provides the mechanical properties of the seal—compressibility, resilience, and the ability to fill imperfections in the flange faces.

The outer shell, or "envelope," is made of PTFE (Polytetrafluoroethylene). This shell completely isolates the inner core from the media flowing through the pipe, ensuring only the PTFE makes contact.

The Role of the PTFE Envelope

The PTFE shell provides one primary, critical benefit: near-universal chemical resistance.

PTFE is inert to almost all industrial chemicals, including strong acids, solvents, and bases. This makes it the ideal choice for services where other gasket materials would quickly degrade.

It also provides a non-stick, low-friction surface, which is beneficial for cleanability and preventing material adhesion.

The Function of the Core Insert

While PTFE is chemically robust, it is mechanically weak and prone to a phenomenon called "cold flow" or creep, where it deforms under pressure.

The inner core material, often made of corrugated metal, graphite, or synthetic fibers, provides the mechanical strength and resilience that pure PTFE lacks. This core gives the gasket the ability to maintain a tight seal under the compressive load of the flange bolts.

Key Industrial Applications

The unique composite design of PTFE envelope gaskets makes them the preferred solution in several demanding industrial scenarios.

Protecting Delicate Flanges

This is a primary application. Flanges made from glass, enamel, plastic, or fiberglass-reinforced plastic (FRP) can easily be cracked or damaged by the high seating stress required for solid gaskets.

The soft, compressible nature of an envelope gasket's core allows it to create a tight seal with much lower bolt torque, protecting these fragile and expensive flange surfaces.

Handling Aggressive Chemicals

In industries like Chemical Processing, Petrochemicals, and Pulp & Paper, piping systems transport highly corrosive substances.

PTFE envelope gaskets provide a reliable seal that will not be chemically attacked, preventing dangerous leaks and costly downtime.

Ensuring Purity and Non-Contamination

The Pharmaceutical, Food & Beverage, and Biotechnology industries demand extreme purity.

Because PTFE is non-toxic, non-reactive, and FDA-approved for food contact, it ensures that the gasket itself does not contaminate the process media.

High-Integrity Sealing

These gaskets are also used in Power Generation and Oil & Gas applications to seal connections on pressure vessels, piping systems, and valves where a stable, durable seal is required in corrosive or high-temperature environments.

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are not a universal solution. Understanding their limitations is key to using them correctly.

Temperature Limitations

The primary limitation is the temperature ceiling of the PTFE material itself, which is typically around 500°F (260°C). Beyond this point, the PTFE will begin to degrade, compromising the seal.

Susceptibility to Creep

Although the core material adds stability, the PTFE shell is still susceptible to cold flow. In applications with high pressures and thermal cycling, the gasket can slowly deform, leading to a loss of bolt torque over time. Periodic re-torquing may be necessary.

Not for Extreme Pressure

For extremely high-pressure applications, a more robust gasket design like a spiral wound or ring-type joint (RTJ) gasket is generally a better choice. Envelope gaskets are best suited for low-to-medium pressure classes.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE envelope gasket is the correct choice for your goal.

- If your primary focus is protecting delicate flanges (glass-lined, plastic, FRP) or handling aggressive chemicals: A PTFE envelope gasket is the ideal solution due to its combination of compressibility and an inert sealing surface.

- If your primary focus is ensuring process purity (food, pharma, biotech): The non-toxic and non-reactive properties of the PTFE envelope make it an excellent choice for preventing contamination.

- If your primary focus is extreme temperature (above 500°F / 260°C) or very high pressure: You should evaluate a spiral wound gasket with a suitable filler material, as it will offer better resistance to creep and temperature degradation.

By matching the unique construction of the PTFE envelope gasket to the specific demands of the application, you can ensure a safe, reliable, and long-lasting seal.

Summary Table:

| Application | Primary Benefit | Key Industries |

|---|---|---|

| Protecting Delicate Flanges | Low seating stress prevents damage to glass, plastic, or FRP surfaces | Chemical Processing, Pharmaceuticals |

| Handling Aggressive Chemicals | PTFE shell is inert to acids, solvents, and bases | Petrochemicals, Pulp & Paper |

| Ensuring Process Purity | Non-toxic, non-reactive, FDA-compliant sealing surface | Food & Beverage, Biotechnology |

| High-Integrity Sealing | Reliable performance in corrosive or moderate-temperature environments | Power Generation, Oil & Gas |

Need a reliable, chemically inert seal for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets tailored to your exact specifications. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production ensures a perfect seal that protects your equipment and processes.

We offer:

- Custom Fabrication: From prototypes to high-volume orders.

- Expert Material Selection: Ensuring optimal performance for your specific chemical and mechanical requirements.

- Durability and Precision: Engineered to withstand aggressive media and protect delicate flange surfaces.

Let us help you solve your toughest sealing challenges. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability