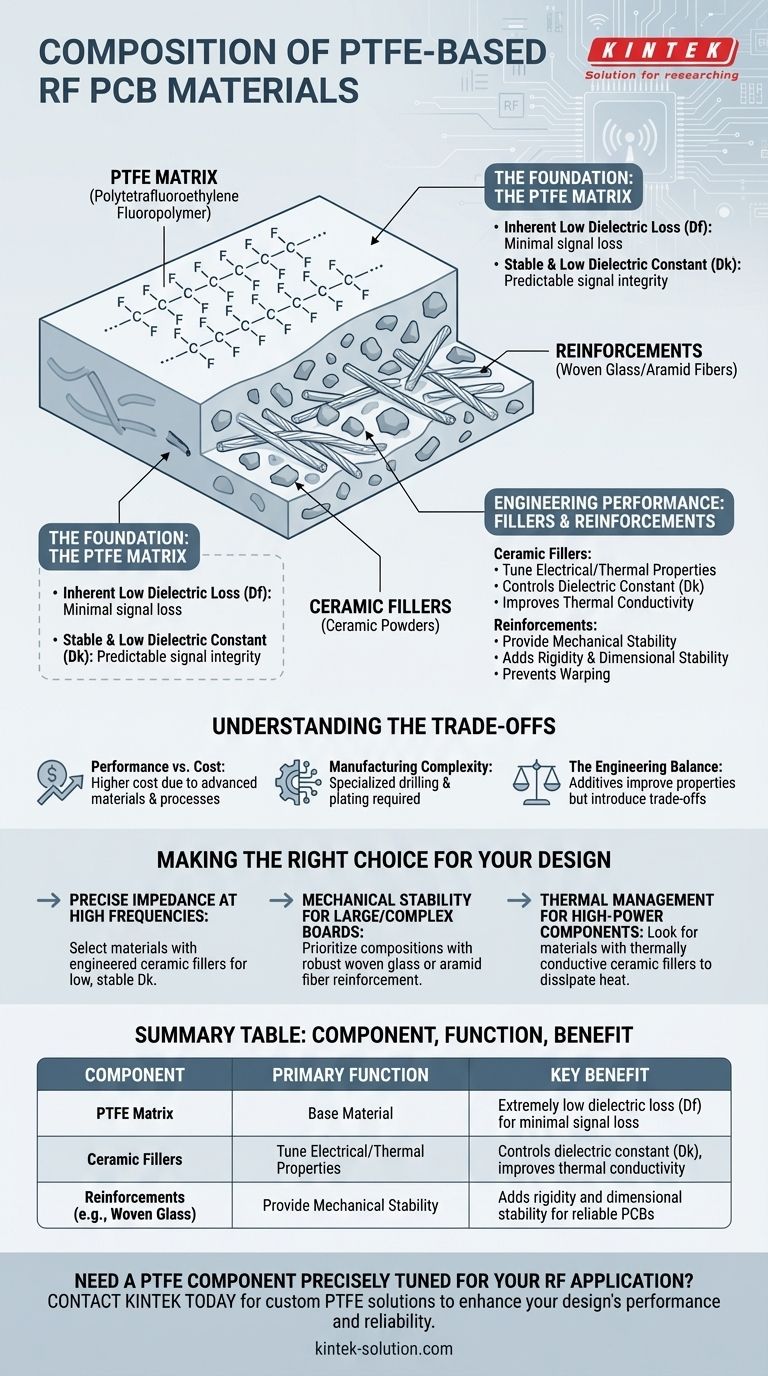

At its core, a PTFE-based material for an RF PCB is a composite. It consists of a Polytetrafluoroethylene (PTFE) matrix that is enhanced with specific fillers and reinforcements. These additions are not arbitrary; they are precisely engineered to improve the material's mechanical, thermal, and electrical properties beyond what pure PTFE can offer.

The central challenge with pure PTFE is that its exceptional electrical properties for high-frequency signals are coupled with poor mechanical and thermal stability. Therefore, PCB material manufacturers create sophisticated composites, adding fillers and reinforcements to gain structural integrity and thermal control while preserving PTFE's vital RF performance.

The Foundation: The PTFE Matrix

What is PTFE?

PTFE, or Polytetrafluoroethylene, is a synthetic fluoropolymer. It is composed of a long chain of carbon atoms completely surrounded by fluorine atoms.

The incredibly strong carbon-fluorine bonds are the source of PTFE's most desirable characteristics. These bonds make the material chemically non-reactive, resistant to moisture, and electrically insulating.

Why PTFE for RF Applications?

For high-frequency circuits, PTFE is a superior base material due to its inherently very low dielectric loss (also known as low Dissipation Factor or Df). This means less of the RF signal energy is lost as heat as it travels through the material.

It also provides a stable and low dielectric constant (Dk), which is critical for maintaining predictable impedance and signal integrity at microwave and millimeter-wave frequencies.

The Inherent Limitations of Pure PTFE

While electrically excellent, pure PTFE is mechanically soft and dimensionally unstable, especially with changes in temperature. This makes it unsuitable on its own for manufacturing rigid, multi-layer printed circuit boards that must endure soldering and environmental stress.

Engineering Performance: Fillers and Reinforcements

To overcome the limitations of pure PTFE, manufacturers embed other materials into the PTFE matrix. The two primary categories are fillers and reinforcements.

The Role of Ceramic Fillers

Ceramic powders are the most common type of filler used in RF laminates. Their primary purpose is to engineer the material's electrical and thermal properties.

By carefully selecting the type and amount of ceramic filler, manufacturers can precisely control the final dielectric constant (Dk) of the composite. This allows them to offer a wide portfolio of materials tailored to specific impedance requirements. Certain ceramics also significantly improve thermal conductivity.

The Role of Reinforcements

Reinforcements are added to provide mechanical rigidity and dimensional stability. They form a structural skeleton within the PTFE matrix, preventing the material from warping or changing shape during fabrication and operation.

Common reinforcements include woven glass or, for more demanding applications, aramid fibers. This structure is essential for creating reliable, multi-layer PCBs.

A Unified Composite Material

The final laminate is not simply a mixture but a true composite. The PTFE matrix encapsulates the ceramic fillers and the reinforcement structure, binding them together into a single, cohesive sheet with a unique combination of electrical, mechanical, and thermal behaviors.

Understanding the Trade-offs

Performance vs. Cost

PTFE-based composites are significantly more expensive than standard PCB materials like FR-4. The advanced materials and complex manufacturing processes required contribute to this higher cost.

Manufacturing Complexity

These materials can be more challenging to work with during PCB fabrication. The softness of the PTFE matrix requires specialized drilling, routing, and plating processes compared to conventional rigid boards.

The Engineering Balance

Every additive represents a trade-off. For example, adding more woven glass reinforcement improves mechanical stability but can introduce minor inconsistencies in the dielectric constant. The goal of the material scientist is to find the optimal balance that meets a specific application's performance targets.

Making the Right Choice for Your Design

Choosing the correct PTFE-based material is about matching its specific composition to your primary design goal.

- If your primary focus is precise impedance at high frequencies: Select a material with ceramic fillers engineered to provide a low, stable, and tightly controlled dielectric constant.

- If your primary focus is mechanical stability for large or complex boards: Prioritize a composition with a robust woven glass or aramid fiber reinforcement.

- If your primary focus is thermal management for high-power components: Look for materials that specifically use thermally conductive ceramic fillers to help dissipate heat.

By understanding that these materials are engineered composites, you can select a laminate that is precisely tuned to your application's unique demands.

Summary Table:

| Component | Primary Function | Key Benefit |

|---|---|---|

| PTFE Matrix | Base Material | Extremely low dielectric loss (Df) for minimal signal loss |

| Ceramic Fillers | Tune Electrical/Thermal Properties | Controls dielectric constant (Dk), improves thermal conductivity |

| Reinforcements (e.g., Woven Glass) | Provide Mechanical Stability | Adds rigidity and dimensional stability for reliable PCBs |

Need a PTFE component precisely tuned for your RF application?

At KINTEK, we specialize in the custom fabrication of high-performance PTFE components, including seals, liners, and labware. Our expertise in precision production ensures your parts meet the exacting electrical and mechanical demands of RF, semiconductor, medical, and industrial applications—from prototype to high-volume production.

Contact KINTEK today to discuss how our custom PTFE solutions can enhance your design's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech