In short, an O-ring is a circular gasket designed to block the escape or entry of fluids and gases. It functions by being compressed into a groove, where its material deforms to fill the gap between two mating surfaces, creating a highly effective and reliable seal.

The genius of the O-ring lies in its simplicity. It leverages both mechanical compression and system pressure to deform and perfectly conform to a machined groove, blocking any potential leak paths for liquids or gases.

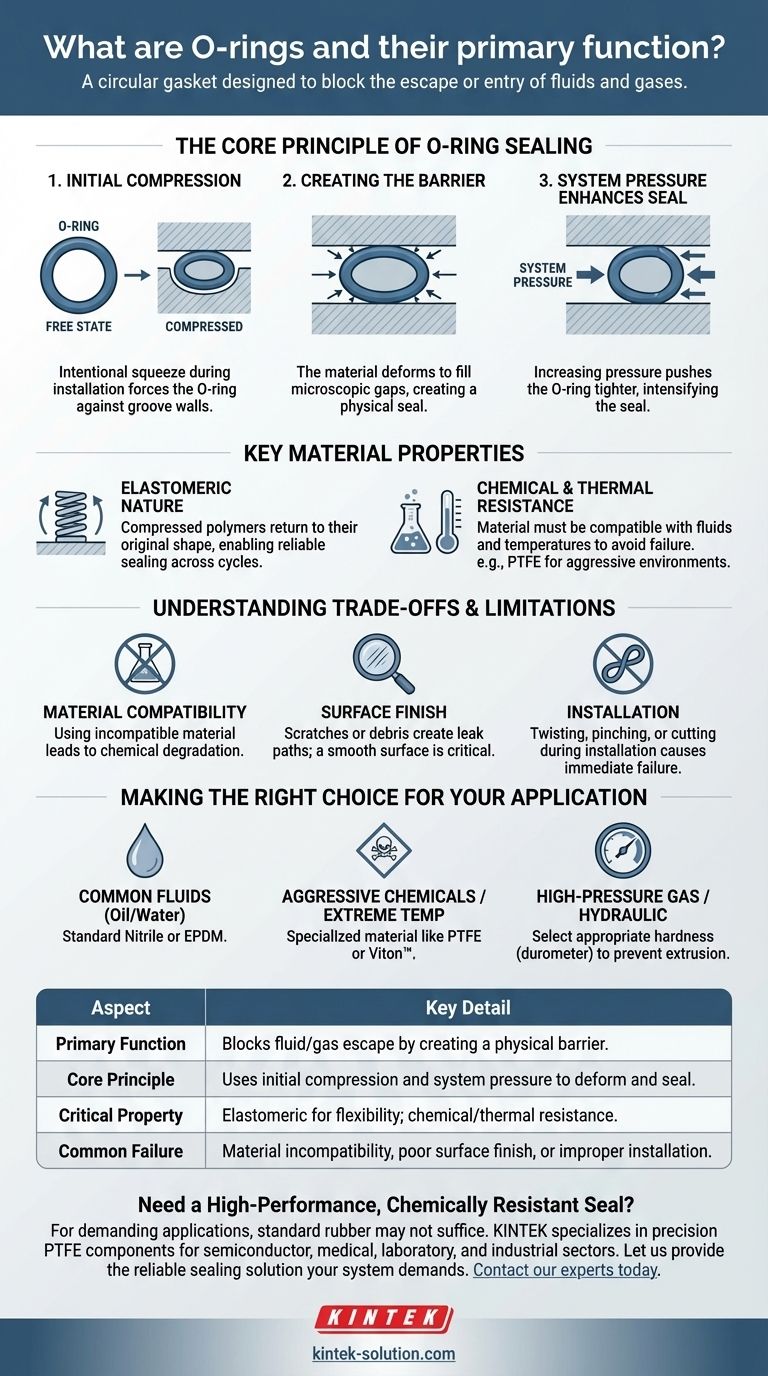

The Core Principle of O-Ring Sealing

An O-ring's effectiveness comes from its predictable response to physical forces. It's a precisely engineered component that relies on its shape, material, and the design of the hardware it sits in.

The Role of Initial Compression

An O-ring is always designed to be slightly larger than the space it will occupy. This intentional "squeeze" or compression during installation is the first step in creating the seal.

This initial compression forces the O-ring's material to press firmly against the inner and outer walls of the groove, establishing a baseline seal even when the system is not pressurized.

Creating the Physical Barrier

The O-ring itself is the barrier. Made from flexible, hydrophobic (water-repelling) materials, it physically obstructs the space between two parts.

When compressed, the O-ring deforms from its circular cross-section into a more oval shape, ensuring there are no microscopic gaps for fluids to pass through.

How System Pressure Enhances the Seal

A key aspect of O-ring design is its ability to use the system's own pressure to its advantage.

As pressure increases on one side, it pushes the O-ring more forcefully against the opposite wall of the groove. This action intensifies the sealing force, making the seal even tighter and more robust as pressure rises.

Key Material Properties

The material an O-ring is made from is just as critical as its dimensions. The choice of material dictates its performance in different chemical and thermal environments.

Elastomeric Nature

O-rings are typically made from elastomers—polymers with elastic properties. This allows them to be compressed and then return to their original shape when the force is removed, enabling reliable sealing across many cycles.

Chemical and Thermal Resistance

The material must be chemically compatible with the fluid it is sealing. Using the wrong material can cause it to swell, harden, crack, and ultimately fail.

For example, specialized materials like PTFE (Teflon) are used in applications involving aggressive chemicals or extreme temperatures where standard rubber compounds would quickly degrade.

Understanding the Trade-offs and Limitations

While highly effective, O-rings are not infallible. Their performance depends entirely on correct design, material selection, and installation.

Material Compatibility is Non-Negotiable

The single most common cause of O-ring failure is selecting a material that is incompatible with the system's fluid or operating temperature. This can lead to chemical degradation and a complete loss of the seal.

Surface Finish is Critical

O-rings require a smooth, clean surface to seal against. Scratches, nicks, or debris on the mating surfaces can create tiny channels that allow fluid to bypass the seal, no matter how well the O-ring is designed.

Installation Can Cause Failure

The O-ring must be installed carefully. Twisting it during installation can create stress points and an inconsistent sealing surface. Likewise, pinching or cutting the O-ring on sharp edges during assembly will create an immediate leak path.

Making the Right Choice for Your Application

Selecting the correct O-ring requires understanding your system's specific demands.

- If your primary focus is containing common fluids like oil or water at moderate temperatures: A standard nitrile or EPDM rubber O-ring is typically the most reliable and cost-effective choice.

- If your primary focus is sealing against aggressive chemicals or extreme temperatures: A specialized material like PTFE (Teflon) or Viton™ is necessary to ensure long-term integrity.

- If your primary focus is a high-pressure gas or hydraulic system: You must select an O-ring with the appropriate hardness (durometer) and ensure the groove is designed to prevent extrusion under pressure.

Ultimately, the O-ring is a foundational component whose proper selection and installation are critical to the integrity of any sealed system.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Blocks the escape or entry of fluids and gases by creating a physical barrier. |

| Core Principle | Uses initial compression and system pressure to deform and seal a machined groove. |

| Critical Material Property | Elastomeric nature for flexibility; chemical/thermal resistance for compatibility. |

| Common Failure Causes | Material incompatibility, poor surface finish, or improper installation (twisting/pinching). |

Need a High-Performance, Chemically Resistant Seal?

For demanding applications involving aggressive chemicals, extreme temperatures, or requiring high purity, standard rubber O-rings may not be sufficient. KINTEK specializes in manufacturing precision PTFE components, including seals and O-rings, for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Let us provide the reliable sealing solution your system demands. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments