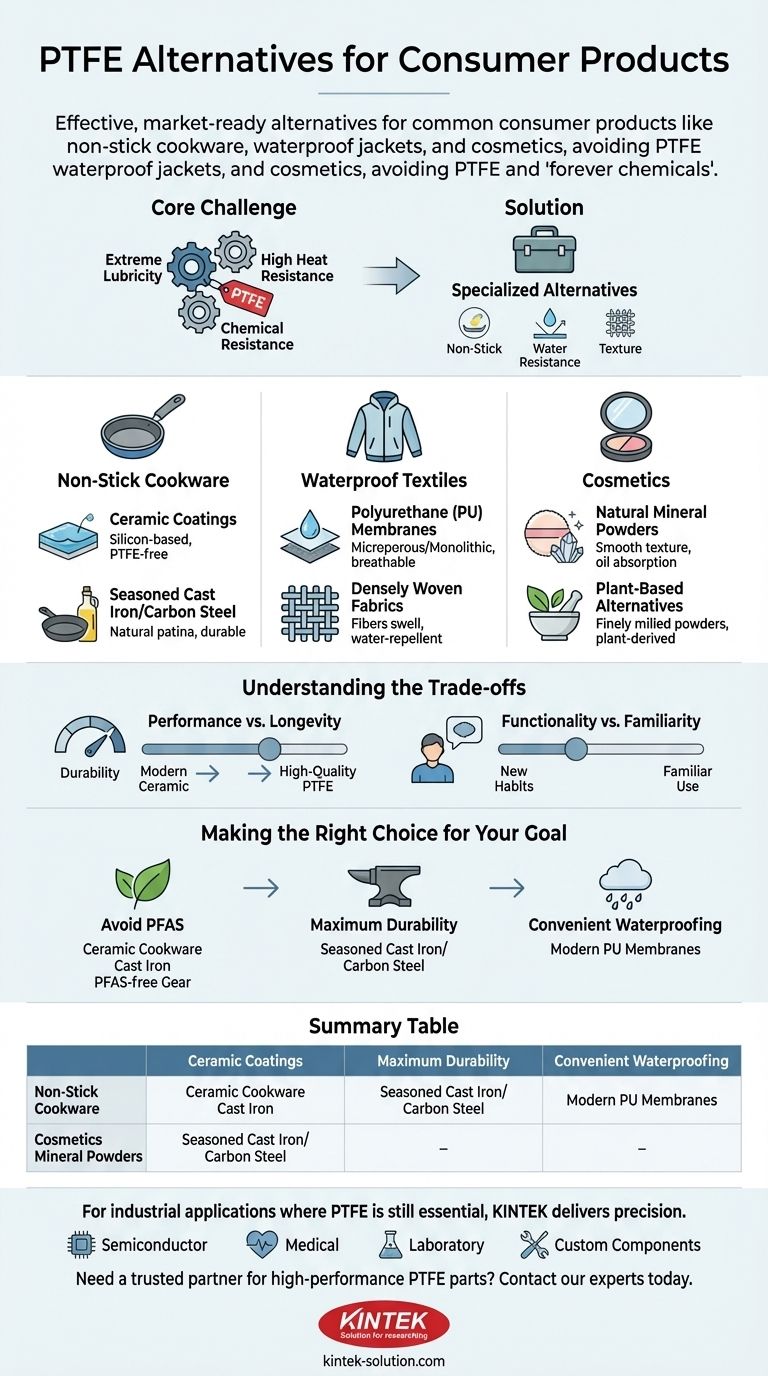

For consumers seeking to avoid PTFE, several effective, market-ready alternatives now exist for common products like non-stick cookware, waterproof jackets, and cosmetics. While replacing PTFE in demanding industrial settings remains a challenge, the consumer goods industry has successfully identified and implemented safer materials for everyday use.

The core challenge is not finding a single material that does everything PTFE can. Instead, the solution is to select from a range of specialized alternatives, each designed to replicate a specific PTFE function—like non-stick performance or water resistance—without the associated health and environmental concerns.

Why Seek Alternatives to PTFE?

Polytetrafluoroethylene (PTFE) is a synthetic polymer valued for its unique properties. However, growing awareness of its potential impact has driven the search for substitutes.

The Problem with 'Forever Chemicals'

PTFE is a member of the PFAS family of chemicals, often called 'forever chemicals' because they do not break down easily in the environment. Studies have raised concerns about the potential for adverse effects on human health, prompting consumers and regulators to demand safer materials.

PTFE's High-Performance Benchmark

Replacing PTFE is complex because it excels in several areas simultaneously. It is known for its extreme lubricity (creating a non-stick surface), high resistance to heat, and near-total resistance to chemical reactions. An effective alternative must match the performance that matters for a specific product.

Proven PTFE Alternatives in Consumer Goods

For the most common consumer applications, the industry has developed several reliable alternatives.

For Non-Stick Cookware

The primary function of PTFE in cookware is to provide a non-stick surface. Modern alternatives achieve this through different materials and technologies.

- Ceramic Coatings: These are a popular choice, typically using a silicone-based polymer applied in a gel form that is then cured. They offer excellent non-stick performance and are free of PTFE and other PFAS.

- Seasoned Cast Iron & Carbon Steel: These traditional materials develop a naturally non-stick surface (a "patina") through a process of seasoning with oil. They are extremely durable and can last for generations.

For Waterproof Textiles

In outdoor apparel, expanded PTFE (ePTFE) is used to create waterproof yet breathable membranes.

- Polyurethane (PU) Membranes: Modern waterproof jackets frequently use microporous or monolithic polyurethane membranes. These technologies effectively block water from the outside while allowing water vapor (sweat) to escape.

- Densely Woven Fabrics: Some brands use specially engineered, tightly woven cotton or synthetic fabrics. The fibers swell when wet, sealing the gaps to prevent water from penetrating while remaining breathable.

For Cosmetics

PTFE was often used in cosmetics to give products a smooth, silky feel or to act as a bulking agent.

- Natural Mineral Powders: Ingredients like silica, mica, and corn starch are now widely used to provide a similar smooth texture and absorb excess oil.

- Plant-Based Alternatives: Many brands have shifted to finely milled, plant-derived powders to achieve the desired product consistency and feel on the skin.

Understanding the Trade-offs

Choosing an alternative to PTFE involves balancing different factors. There is no single "best" material, only the right material for a specific goal.

Performance vs. Longevity

While modern ceramic non-stick coatings perform exceptionally well, they may not have the same long-term durability as high-quality PTFE, especially if subjected to very high heat or abrasive utensils. Similarly, seasoned cast iron requires ongoing maintenance to preserve its non-stick layer.

Functionality vs. Familiarity

Alternatives often require a slight change in user habits. For example, cast iron cookware has different heating properties and cleaning requirements than a traditional PTFE pan. PU-based waterproof jackets may have a different feel or level of breathability compared to their ePTFE counterparts.

Industrial vs. Consumer Needs

It is crucial to distinguish between consumer and industrial applications. The references correctly note that finding replacements for industrial pipes, seals, and chemical-resistant coatings is far more difficult due to the extreme heat and corrosive environments involved. For consumer goods, the performance requirements are much less severe, making alternatives a practical reality.

Making the Right Choice for Your Goal

Your decision should be guided by your primary objective.

- If your primary focus is avoiding PFAS: Choose ceramic-coated cookware, seasoned cast iron, or look for outdoor gear explicitly marketed as having a "PFAS-free" or "PU" membrane.

- If your primary focus is maximum durability in cookware: Seasoned cast iron or carbon steel are unmatched, though they require more maintenance.

- If your primary focus is convenient, high-performance waterproofing: Modern polyurethane membranes offer excellent performance that rivals traditional PTFE-based options for most consumer uses.

Ultimately, technological innovation has provided a new generation of materials, empowering you to make choices that align with both your performance needs and your personal values.

Summary Table:

| Product Category | Common PTFE Use | Leading Alternatives |

|---|---|---|

| Non-Stick Cookware | Non-stick coating | Ceramic coatings, Seasoned cast iron/carbon steel |

| Waterproof Textiles | Waterproof membrane | Polyurethane (PU) membranes, Densely woven fabrics |

| Cosmetics | Smooth texture/bulking agent | Natural mineral powders (silica, mica), Plant-based powders |

For industrial applications where PTFE is still essential, KINTEK delivers precision.

While consumer products have moved to alternatives, specialized industries like semiconductor, medical, and laboratory sectors rely on the unmatched chemical resistance and performance of PTFE for critical components like seals, liners, and labware.

KINTEK manufactures high-quality, custom PTFE components—from prototypes to high-volume orders—ensuring the precision and reliability your operations demand.

Need a trusted partner for high-performance PTFE parts? Contact our experts today to discuss your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications