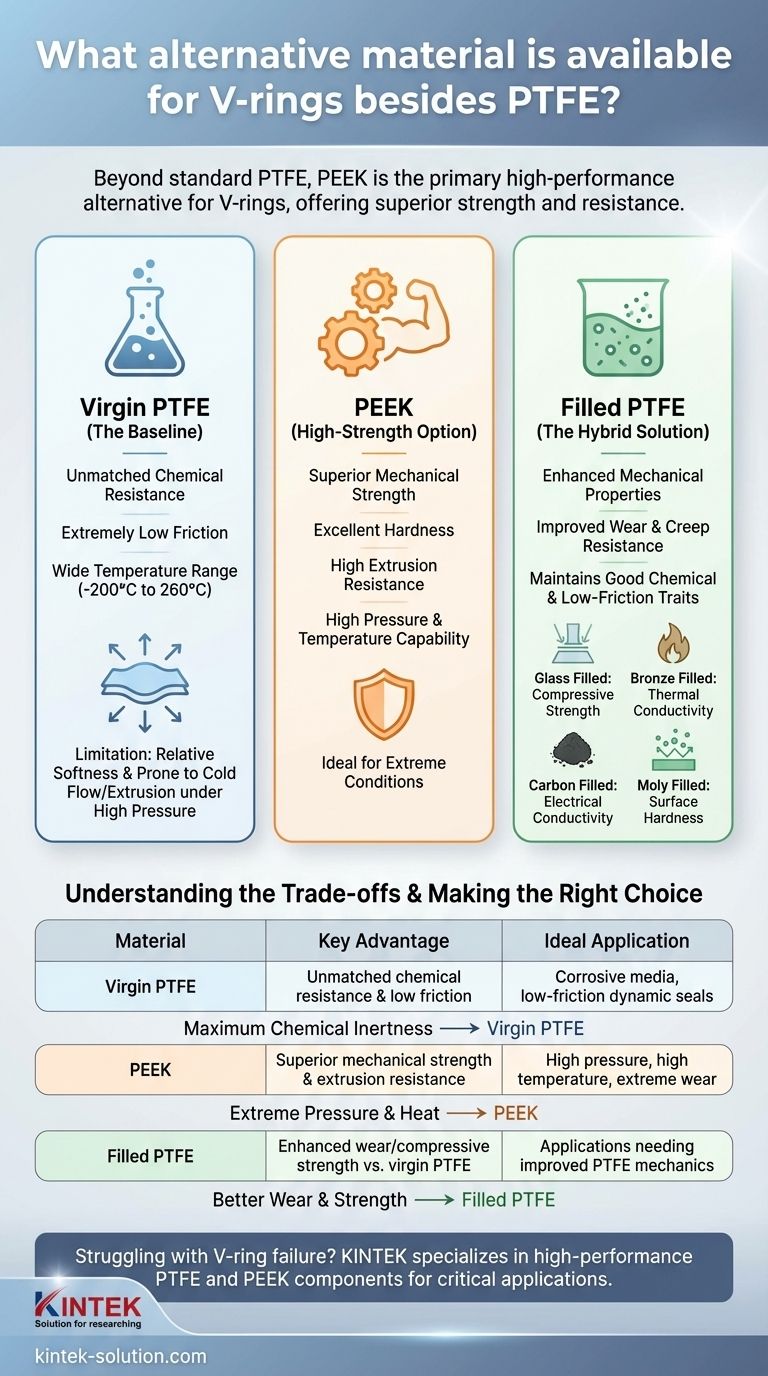

Beyond standard PTFE, the primary high-performance alternative material for V-rings is PEEK (Polyetheretherketone). While virgin PTFE is prized for its extremely low friction and broad chemical resistance, PEEK offers superior mechanical strength, hardness, and resistance to extrusion under high pressure and temperature. The best choice depends entirely on the specific demands of your sealing application.

The core decision is a trade-off between chemical inertness and mechanical robustness. PTFE provides the ultimate chemical and low-friction performance, while PEEK delivers the strength needed to withstand extreme pressure, wear, and high temperatures.

The Baseline: Understanding PTFE's Role

Polytetrafluoroethylene (PTFE) is often the default material for V-rings and other seals for several compelling reasons. Understanding its inherent strengths and weaknesses is key to knowing when to select an alternative.

### Unmatched Chemical Resistance

PTFE is virtually inert, resisting almost all industrial chemicals and solvents. This makes it an essential choice for applications involving corrosive media.

### Extremely Low Friction

With one of the lowest coefficients of friction of any solid, PTFE is ideal for dynamic sealing applications where reducing drag and preventing stick-slip is critical.

### Wide Temperature Range

PTFE performs reliably across an exceptionally broad temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F).

### The Inherent Limitation

The primary drawback of virgin PTFE is its relative softness. Under high pressure, it can be prone to cold flow (creep) and extrusion through the seal housing clearances, leading to premature failure.

Exploring the Alternatives: PEEK and Filled PTFE

When the mechanical demands of an application exceed the capabilities of virgin PTFE, two main paths emerge: switching to a fundamentally stronger polymer like PEEK or enhancing PTFE with fillers.

### PEEK: The High-Strength Option

PEEK is a high-performance thermoplastic known for its excellent mechanical properties. It is significantly harder and more rigid than PTFE, providing exceptional resistance to wear and extrusion, particularly in high-pressure and high-temperature environments.

### Filled PTFE: The Hybrid Solution

A common strategy is to enhance PTFE by blending it with reinforcing fillers. This approach improves specific mechanical properties while retaining most of PTFE's desirable low-friction and chemical characteristics.

### Common Filler Types and Their Benefits

- Glass Filled PTFE: Increases compressive strength and improves wear resistance.

- Bronze Filled PTFE: Significantly increases thermal conductivity and resistance to wear and creep.

- Carbon Filled PTFE: Improves electrical conductivity and offers good wear resistance.

- Molybdenum Disulphide (Moly) Filled PTFE: Increases surface hardness and wear resistance.

Understanding the Trade-offs

Choosing the right material requires a clear understanding of what you gain and what you might sacrifice. There is no single "best" material, only the most appropriate one for the job.

### PEEK vs. PTFE

The choice here is clear. Select PEEK for its superior mechanical strength and extrusion resistance. Select PTFE for its superior chemical resistance and lower friction coefficient.

### Filled vs. Virgin PTFE

Adding fillers dramatically improves PTFE's mechanical properties, especially its resistance to creep and wear. However, these fillers can sometimes slightly reduce the overall chemical resistance compared to virgin PTFE and may increase the friction coefficient.

### Cost and Manufacturing

High-performance materials like PEEK are generally more expensive than PTFE. Similarly, filled PTFE grades are typically more costly than their unfilled counterparts due to the additional processing involved.

Making the Right Choice for Your Goal

Your application's primary challenge should guide your material selection.

- If your primary focus is maximum chemical inertness and the lowest possible friction: Virgin PTFE remains the unparalleled choice.

- If you need better wear resistance and compressive strength but still require good chemical compatibility: A filled PTFE, such as glass or bronze filled, is your most effective solution.

- If your primary focus is withstanding extreme pressure, high temperatures, and preventing seal extrusion: PEEK is the superior material for maximum mechanical integrity.

Ultimately, a precise analysis of your system's pressure, temperature, media, and mechanical loads will lead you to the correct material decision.

Summary Table:

| Material | Key Advantage | Ideal For Application |

|---|---|---|

| Virgin PTFE | Unmatched chemical resistance & low friction | Corrosive media, low-friction dynamic seals |

| PEEK | Superior mechanical strength & extrusion resistance | High pressure, high temperature, extreme wear |

| Filled PTFE | Enhanced wear/compressive strength vs. virgin PTFE | Applications needing improved PTFE mechanics |

Struggling with V-ring failure under pressure or temperature?

KINTEK specializes in manufacturing high-performance PTFE and PEEK components, including custom V-rings, for the semiconductor, medical, laboratory, and industrial sectors. We deliver the precision and material expertise you need—from prototypes to high-volume orders—to solve your toughest sealing challenges.

Let our experts help you select the perfect material for your application. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs