At its core, the purchase of a PTFE expansion joint is not just a transaction for a physical part, but an investment in a comprehensive solution. The most critical services offered are expert consulting, custom engineering, and detailed design support, all geared towards ensuring the joint functions perfectly within your specific operational context.

The key takeaway is that specialized services are not optional add-ons; they are an integral part of the procurement process. These services ensure the expansion joint is precisely matched to your system's pressure, temperature, chemical, and movement requirements, mitigating risk and maximizing operational lifespan.

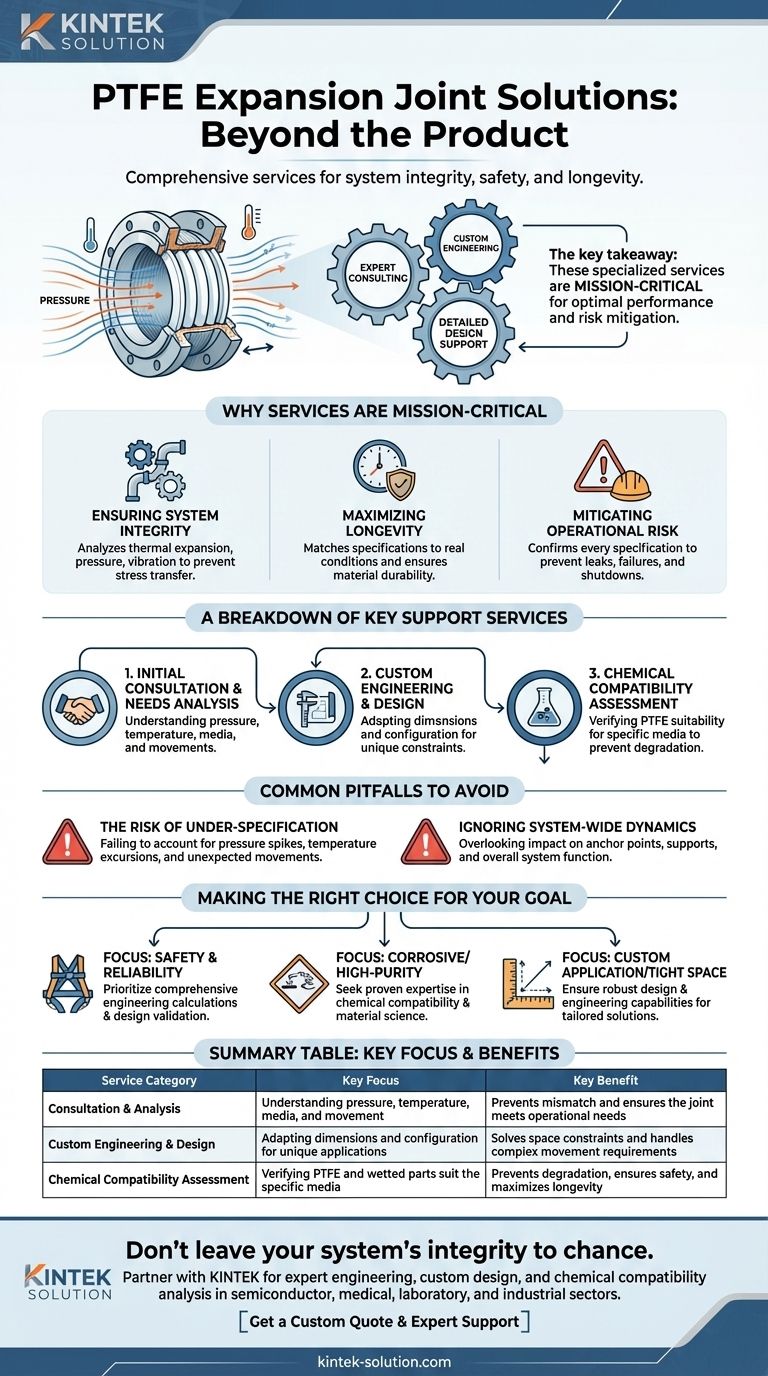

Why These Services Are Mission-Critical

A PTFE expansion joint is a dynamic component that absorbs stress and movement within a piping system. A failure here can lead to costly downtime and significant safety hazards. Ancillary services are designed to prevent this by treating the joint as a critical piece of engineered equipment, not a simple commodity.

Ensuring System Integrity

The forces at play within an industrial piping system—thermal expansion, pressure fluctuations, and vibration—are complex. Expert engineering services analyze these factors to select or design a joint that can safely manage them without transferring stress to the wider system.

Maximizing Longevity

Premature failure is often caused by a mismatch between the expansion joint's specifications and the actual operating conditions. A thorough consultation process, including a chemical compatibility assessment, ensures the selected materials and design will withstand the specific media and environment for the long term.

Mitigating Operational Risk

The right design and engineering support function as a form of risk management. By confirming every specification and understanding the application's unique challenges, a knowledgeable supplier helps prevent leaks, catastrophic failures, and unscheduled shutdowns.

A Breakdown of Key Support Services

While services can be tailored to a project, they generally fall into three interconnected categories that guide you from initial concept to a final, reliable solution.

Initial Consultation & Needs Analysis

This is the foundational step. An expert partner works to understand your core challenge, including the system's operating pressure and temperature, the media being transported, and the specific movements (axial, lateral, or angular) that need to be absorbed.

Custom Engineering & Design

Standard, off-the-shelf products do not fit every application. When dealing with tight spaces, unique movement requirements, or extreme environmental conditions, custom engineering is required. This service adapts the joint's dimensions, flange configuration, and overall design to your exact needs.

Chemical Compatibility Assessment

PTFE is highly resistant to many chemicals, but its performance can be affected by specific compounds, concentrations, and temperatures. A compatibility assessment verifies that the PTFE liner and other wetted parts are fully suited for the media passing through, preventing degradation and ensuring safety.

Common Pitfalls to Avoid

Understanding the value of these services becomes clearer when you consider the risks of proceeding without them. A "product-only" mindset can lead to significant and preventable problems.

The Risk of Under-Specification

Simply choosing a joint based on pipe size and a general pressure rating is a common mistake. Without a full analysis, the joint may not be rated for pressure spikes, temperature excursions, or unexpected movements, leading to a high probability of premature failure.

Ignoring System-Wide Dynamics

An expansion joint impacts the entire piping system, including its anchor points and supports. A supplier providing only the part will not account for these dynamics. A true partner offers design support that considers how the joint will function as part of the complete, integrated system.

Making the Right Choice for Your Goal

Selecting a PTFE expansion joint solution is about choosing a partner, not just a product. The level of service you require should align directly with the complexity and criticality of your application.

- If your primary focus is safety and reliability: Prioritize a supplier that provides comprehensive engineering calculations and design validation for your specific operating conditions.

- If your primary focus is managing a corrosive or high-purity system: Seek a partner with proven expertise in chemical compatibility and material science to guarantee material integrity.

- If your primary focus is a custom application or tight space: Ensure the supplier has robust design and engineering capabilities to build a solution tailored to your unique dimensional constraints.

Ultimately, the right services transform a simple component purchase into a long-term strategic investment in your system's integrity.

Summary Table:

| Service Category | Key Focus | Key Benefit |

|---|---|---|

| Consultation & Analysis | Understanding pressure, temperature, media, and movement | Prevents mismatch and ensures the joint meets operational needs |

| Custom Engineering & Design | Adapting dimensions and configuration for unique applications | Solves space constraints and handles complex movement requirements |

| Chemical Compatibility Assessment | Verifying PTFE and wetted parts suit the specific media | Prevents degradation, ensures safety, and maximizes longevity |

Don't leave your system's integrity to chance.

Your PTFE expansion joint is a critical component for safety and performance. At KINTEK, we provide the expert engineering, custom design, and chemical compatibility analysis detailed in this article. We partner with you to ensure a perfect fit for your specific application in the semiconductor, medical, laboratory, and industrial sectors.

Contact us today to discuss your project requirements, from prototypes to high-volume orders. Let's build a reliable solution together.

Get a Custom Quote & Expert Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application