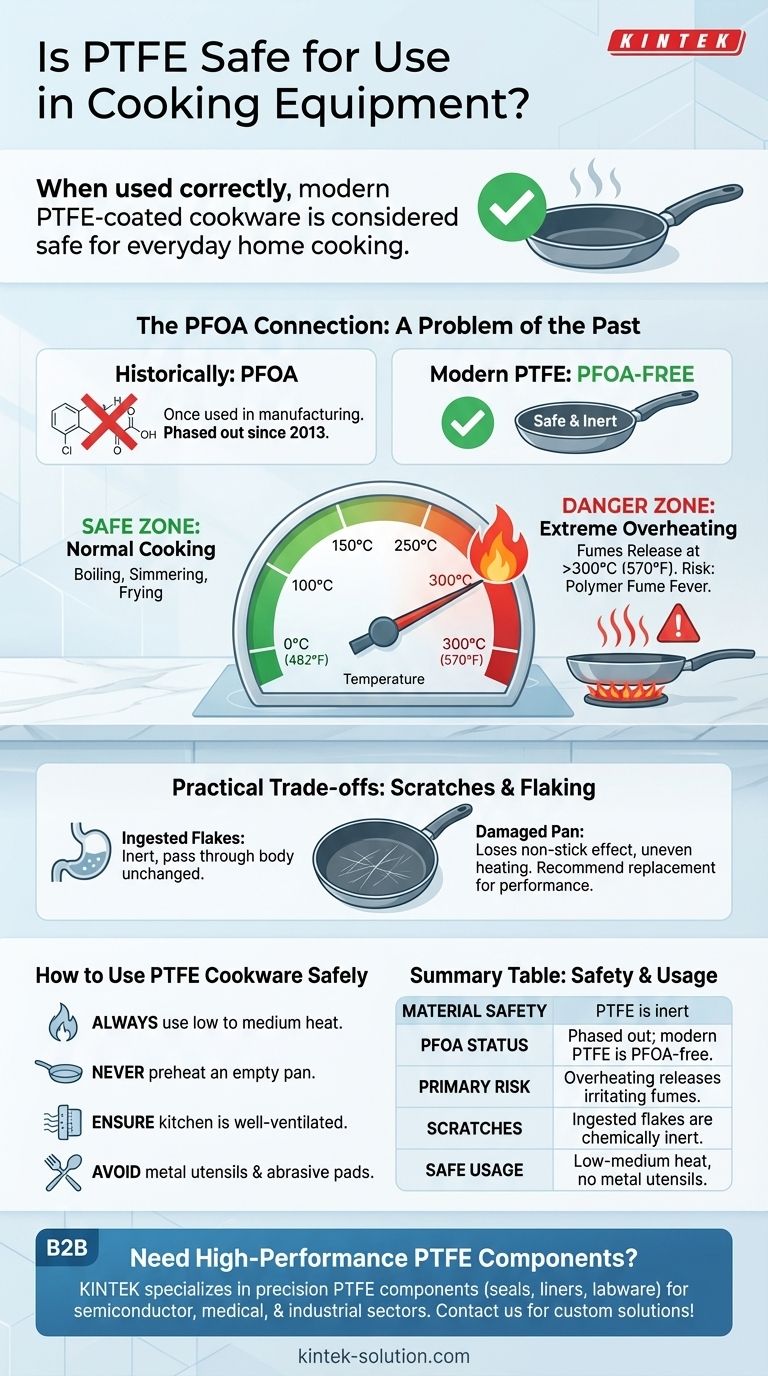

When used correctly, modern PTFE-coated cookware is considered safe for everyday home cooking. The primary health concerns historically associated with non-stick pans stemmed from a manufacturing chemical called PFOA, which is no longer used. The actual risk with modern PTFE lies not in the material itself, but in the fumes it can release when overheated to extreme temperatures.

The core issue is temperature, not toxicity. The PTFE coating on your non-stick pan is inert and safe under normal cooking conditions, but it can degrade and release irritating fumes if heated well above 300°C (570°F).

Understanding PTFE and Its Role in Cookware

What is PTFE?

Polytetrafluoroethylene, or PTFE, is a synthetic polymer known for its extremely low friction. This is what gives non-stick cookware its signature slippery surface.

An Inert and Stable Material

At normal cooking temperatures, PTFE is inert and non-toxic. This means it does not react with food, water, or detergents, which is why it's approved for use in not only cookware but also sensitive medical and food processing applications.

The Source of Health Concerns: PFOA vs. PTFE

The PFOA Connection: A Problem of the Past

Much of the long-term health concern surrounding non-stick pans was linked to PFOA (perfluorooctanoic acid), a chemical once used in the manufacturing process of PTFE.

PFOA has been effectively phased out of cookware production in the United States and many other parts of the world since 2013. Modern PTFE cookware is PFOA-free.

The Real Risk: Extreme Overheating

The only established risk from PTFE itself comes from overheating. When a pan is heated above 300°C (570°F), the PTFE coating can begin to break down and release fumes.

Inhaling these fumes can cause a temporary, flu-like condition known as polymer fume fever. This temperature is far higher than what's needed for boiling, simmering, or frying, and is typically only reached when an empty pan is left on a high-heat burner for an extended period.

Understanding the Practical Trade-offs

Scratches and Flaking

If you accidentally ingest a small flake from a scratched PTFE pan, there is no cause for alarm. Because the material is inert, it will pass through your digestive system unchanged.

However, heavily scratched cookware loses its non-stick effectiveness and may not heat as evenly. It is best to replace pans that are significantly damaged for performance reasons.

Proper Use is Paramount

The safety and longevity of PTFE cookware depend entirely on its proper use. Using metal utensils can cause scratches, and preheating an empty pan on high heat increases the risk of overheating and fume release.

How to Use PTFE Cookware Safely

To eliminate any potential risk, your usage habits are what matter most.

- If your primary focus is safe, everyday cooking: Always use low to medium heat, never preheat an empty pan, and ensure your kitchen is well-ventilated.

- If your primary focus is high-heat searing (e.g., steaks): Use cookware made from cast iron, carbon steel, or stainless steel, as these materials are designed to handle the high temperatures that PTFE is not.

- If your primary focus is cookware longevity: Avoid metal utensils, abrasive scouring pads, and dishwashers, as these can accelerate the breakdown of the non-stick surface.

Ultimately, choosing the right tool for your specific cooking task is the key to both safety and performance.

Summary Table:

| Safety Aspect | Key Information |

|---|---|

| Material Safety | PTFE is inert and non-toxic at normal cooking temperatures (below 300°C/570°F). |

| PFOA Status | PFOA (a former manufacturing chemical) has been phased out of modern PTFE cookware. |

| Primary Risk | Overheating above 300°C can release irritating fumes (polymer fume fever). |

| Scratches/Flaking | Ingested flakes are inert and pass through the body, but damaged pans should be replaced for performance. |

| Safe Usage | Use low-medium heat, avoid preheating empty pans, and do not use metal utensils. |

Need High-Performance PTFE Components for Your Industry?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures materials that meet the highest standards for safety, durability, and performance, even in demanding environments.

Whether you require prototypes or high-volume orders, we deliver custom solutions tailored to your exact needs.

Contact us today to discuss how our PTFE expertise can benefit your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance