Polytetrafluoroethylene (PTFE), widely known by the trade name Teflon™, is a foundational material in nearly every advanced industry. Its unique properties make it an essential component in sectors ranging from chemical processing and aerospace to medical devices and consumer electronics. The material's versatility ensures its use in applications requiring extreme durability and performance.

PTFE’s value comes not from a single feature, but from its rare combination of near-total chemical inertness, an extremely low coefficient of friction, high-temperature tolerance, and excellent electrical insulation. This makes it an indispensable problem-solver for the most demanding engineering challenges.

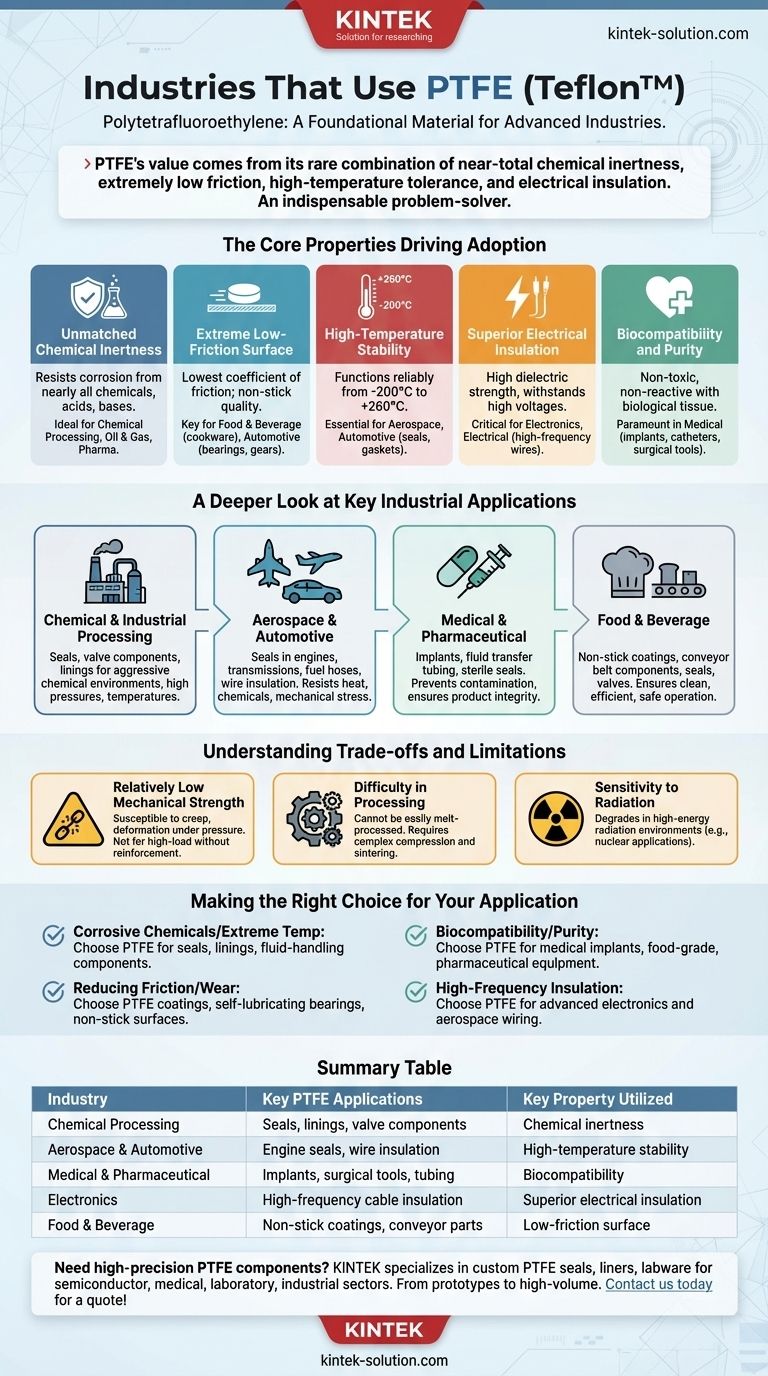

The Core Properties Driving Adoption

The widespread use of PTFE is not accidental. It is a direct result of a specific set of physical and chemical properties that allow it to function where most other materials would fail. Understanding these core traits explains its presence across so many industries.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It resists corrosion and degradation from nearly all industrial chemicals, acids, and bases.

This property makes it the default choice for the chemical processing, oil and gas, and pharmaceutical industries. It is used to create linings for tanks, seals, gaskets, and pipes that handle highly corrosive materials.

Extreme Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, giving it its famous "non-stick" quality.

This is critical in food and beverage applications like non-stick cookware, but it is equally important in automotive and industrial manufacturing for creating low-wear bearings, gears, and other moving parts that require no external lubrication.

High-Temperature Stability

PTFE maintains its integrity and properties across a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal resilience is essential for high-performance applications in the aerospace and automotive industries, where components like seals and gaskets must function reliably in extreme heat and cold.

Superior Electrical Insulation

PTFE is an exceptional electrical insulator with a very high dielectric strength, meaning it can withstand high voltages without breaking down.

This makes it a critical material in the electronics and electrical industries. It is used for insulating high-frequency wires and cables, particularly in computers, aerospace wiring, and radio frequency equipment.

Biocompatibility and Purity

The material is non-toxic and does not react with biological tissue, making it highly biocompatible.

This inertness is paramount in the medical industry, where PTFE is used for implants, such as ligament replacements, and as a coating for surgical devices like catheters and guidewires.

A Deeper Look at Key Industrial Applications

These core properties translate directly into tangible components that solve specific industry problems.

In Chemical and Industrial Processing

PTFE's chemical resistance makes it ideal for seals, valve components, and linings in environments exposed to aggressive chemicals. Its ability to handle high pressures and temperatures ensures operational safety and longevity.

In Aerospace and Automotive

In these industries, every component's reliability is critical. PTFE is used for seals in engines and transmissions, fuel hoses, and wire insulation because it resists degradation from heat, chemicals, and mechanical stress.

In Medical and Pharmaceutical

Beyond implants, PTFE's purity and non-stick surface are used in fluid transfer tubing and sterile seals. This prevents contamination and ensures the integrity of sensitive pharmaceutical and biological products.

In Food and Beverage

The most visible use is non-stick coatings, but PTFE is also used extensively in commercial food processing equipment. Conveyor belt components, seals, and valves made from PTFE ensure clean, efficient, and safe operation.

Understanding the Trade-offs and Limitations

Despite its remarkable advantages, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Relatively Low Mechanical Strength

PTFE is a relatively soft material. It is susceptible to "creep," or deformation under sustained pressure, and is not suitable for high-load structural applications without reinforcement from other materials like glass or carbon.

Difficulty in Processing

Unlike common thermoplastics, PTFE cannot be easily melt-processed or injection molded. It is typically shaped through a more complex and costly process of compression and sintering, which can limit design intricacy.

Sensitivity to Radiation

High-energy radiation, such as gamma rays, can break down PTFE's molecular structure, degrading its mechanical properties. This makes it unsuitable for certain high-radiation environments, like those found in nuclear applications.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is handling corrosive chemicals or extreme temperatures: PTFE is an industry-standard choice for seals, linings, and fluid-handling components.

- If your primary focus is reducing friction and wear: PTFE coatings and machined components are ideal for self-lubricating bearings, non-stick surfaces, and automotive parts.

- If your primary focus is biocompatibility or process purity: Its inert nature makes PTFE a top-tier material for medical implants and food-grade or pharmaceutical equipment.

- If your primary focus is high-frequency electrical insulation: PTFE's exceptional dielectric properties are critical for advanced electronics and aerospace wiring.

Ultimately, PTFE's prevalence stems from its unique ability to perform reliably where most other materials fail.

Summary Table:

| Industry | Key PTFE Applications | Key Property Utilized |

|---|---|---|

| Chemical Processing | Seals, linings, valve components | Chemical inertness |

| Aerospace & Automotive | Engine seals, wire insulation | High-temperature stability |

| Medical & Pharmaceutical | Implants, surgical tools, tubing | Biocompatibility |

| Electronics | High-frequency cable insulation | Superior electrical insulation |

| Food & Beverage | Non-stick coatings, conveyor parts | Low-friction surface |

Need high-precision PTFE components for your industry?

KINTEK specializes in manufacturing custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. We offer precision production from prototypes to high-volume orders to meet your most demanding requirements.

Contact us today to discuss your specific application and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining