Polytetrafluoroethylene (PTFE) is a uniquely versatile material used across a vast range of high-performance sectors. Its adoption is most prominent in industries like chemical processing, aerospace, medical, electronics, and automotive manufacturing, where its unique combination of properties solves critical engineering challenges.

The widespread use of PTFE is not accidental; it is a direct result of its four defining characteristics: extreme chemical inertness, a very high melting point, an exceptionally low coefficient of friction, and excellent electrical insulation. Different industries leverage different combinations of these traits to operate in demanding environments where other materials would fail.

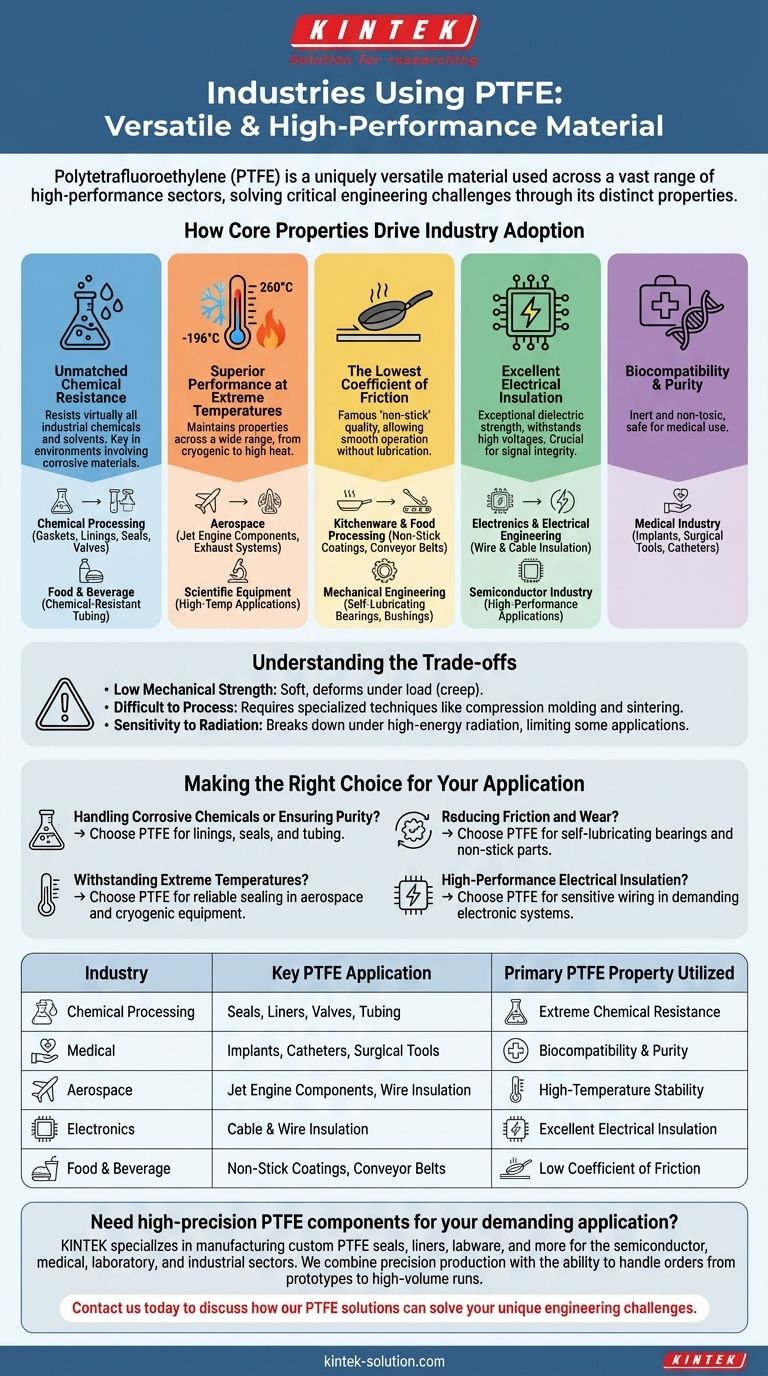

How Core Properties Drive Industry Adoption

Understanding PTFE's applications begins with understanding its fundamental material properties. Each key trait makes it an indispensable problem-solver for a specific set of industrial challenges.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert substances known, resisting virtually all industrial chemicals and solvents. This makes it invaluable in environments involving corrosive materials.

This property is the primary reason for its heavy use in the chemical processing and food and beverage industries for applications like gaskets, vessel linings, seals, valves, and chemical-resistant tubing.

Superior Performance at Extreme Temperatures

PTFE maintains its properties across a wide temperature range, from cryogenic levels up to approximately 260°C (500°F).

This thermal stability is critical for the aerospace industry, where it is used in components for jet engines, as well as in other high-temperature applications like industrial exhaust systems and specialized scientific equipment.

The Lowest Coefficient of Friction

Known for its famous "non-stick" quality, PTFE has one of the lowest coefficients of friction of any solid material. This allows moving parts to operate smoothly without lubrication.

This characteristic is essential in kitchenware (non-stick coatings), food processing (conveyor belts), and mechanical engineering for parts like self-lubricating bearings, bushings, and pump components.

Excellent Electrical Insulation

PTFE is an exceptional electrical insulator with high dielectric strength, meaning it can withstand high voltages without breaking down.

This makes it a top choice in the electronics, semiconductor, and electrical engineering industries for wire and cable insulation, particularly in high-performance applications where signal integrity is crucial.

Biocompatibility and Purity

Because PTFE is inert and non-toxic, it does not react with bodily fluids, making it safe for medical use.

The medical industry relies on this for manufacturing implants, surgical tools, and fluid-handling components like catheters and syringes.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. Acknowledging its limitations is key to using it effectively.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for structural applications and can deform under a sustained load, a phenomenon known as "creep." This is why specialized "bearing grades" often include fillers to improve mechanical stability.

Difficult to Process

PTFE's high melting point makes it challenging to process using conventional thermoplastic methods like injection molding. It requires specialized techniques such as compression molding and sintering, which can increase manufacturing complexity and cost.

Sensitivity to Radiation

High-energy radiation can break down the polymer chains in PTFE, causing it to become brittle and lose its desirable mechanical properties. This limits its use in certain nuclear and space applications.

Making the Right Choice for Your Application

Selecting PTFE is about matching its unique strengths to your specific operational challenge.

- If your primary focus is handling corrosive chemicals or ensuring purity: PTFE's inertness makes it the standard for linings, seals, and tubing in the chemical, food, and medical industries.

- If your primary focus is reducing friction and wear: Its self-lubricating, non-stick surface is ideal for creating maintenance-free bearings, coatings, and pump parts.

- If your primary focus is withstanding extreme temperatures: PTFE provides reliable sealing and component performance in both high-heat aerospace systems and cryogenic equipment.

- If your primary focus is high-performance electrical insulation: Its dielectric strength is critical for protecting sensitive wiring and components in demanding electronic and aerospace applications.

Ultimately, PTFE's value lies in its ability to perform reliably where conventional materials cannot.

Summary Table:

| Industry | Key PTFE Application | Primary PTFE Property Utilized |

|---|---|---|

| Chemical Processing | Seals, Liners, Valves, Tubing | Extreme Chemical Resistance |

| Medical | Implants, Catheters, Surgical Tools | Biocompatibility & Purity |

| Aerospace | Jet Engine Components, Wire Insulation | High-Temperature Stability |

| Electronics | Cable & Wire Insulation | Excellent Electrical Insulation |

| Food & Beverage | Non-Stick Coatings, Conveyor Belts | Low Coefficient of Friction |

Need high-precision PTFE components for your demanding application?

KINTEK specializes in manufacturing custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with the ability to handle orders from prototypes to high-volume runs.

Contact us today to discuss how our PTFE solutions can solve your unique engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials