In short, Teflon bearings are used in nearly every critical industry where conventional lubricated metal bearings would fail. You will find them in aerospace, automotive, chemical processing, food and beverage, medical and pharmaceutical equipment, heavy machinery, and marine applications due to their unique combination of properties.

The widespread use of Teflon (PTFE) bearings is not about a single feature, but its unique ability to solve multiple problems at once: it provides its own lubrication, resists virtually all chemicals, and withstands extreme temperatures where other materials would seize, corrode, or contaminate the environment.

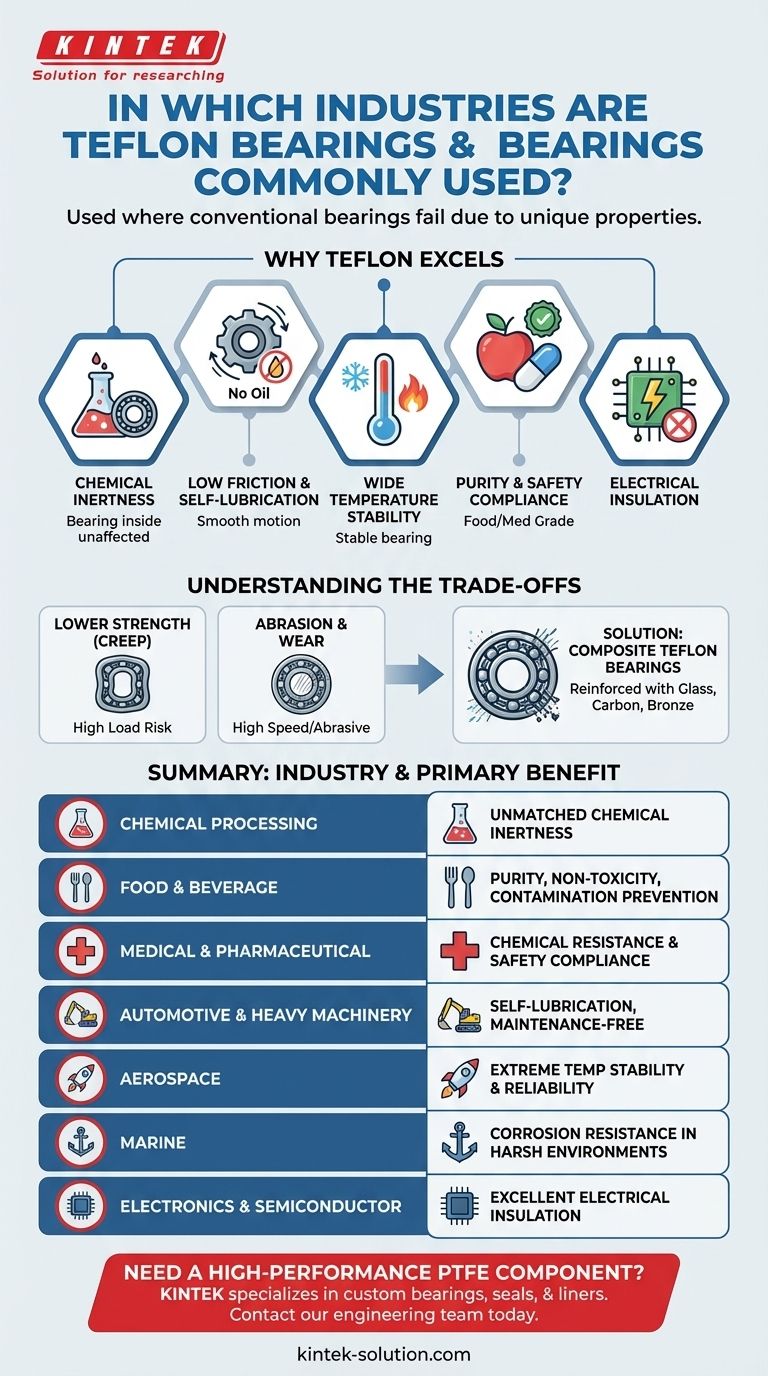

Why Teflon Excels in Demanding Environments

The choice of a bearing material is driven by the specific challenges of its operating environment. Teflon's value comes from a set of inherent properties that make it a superior choice for applications where traditional solutions are impractical or unsafe.

Unmatched Chemical Inertness

Teflon is famously non-reactive. It can withstand exposure to the most aggressive acids, bases, and solvents without degrading or corroding.

This makes it indispensable in chemical processing, pharmaceutical manufacturing, and medical equipment, where the bearing must not react with or contaminate the substance it contacts.

Extremely Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, meaning it is incredibly slippery. This allows for what is known as self-lubrication.

In industries like automotive and heavy machinery, this eliminates the need for external grease or oil, reducing maintenance and removing a potential point of failure or contamination. It ensures smooth, consistent motion without the "stick-slip" judder common in other materials.

Wide Temperature Stability

From cryogenic freezers to high-heat processing ovens, Teflon maintains its structural integrity and performance. It doesn't become brittle in the cold or melt in the heat common to many industrial processes.

This thermal stability is critical for applications in aerospace, where temperatures fluctuate dramatically, and in food processing, which often involves both cooking and freezing.

Purity and Safety Compliance

Because Teflon is inert and non-toxic, it can be manufactured to meet stringent regulatory standards, including those for food and medical contact.

This is the primary reason for its dominance in food and beverage conveyor systems, mixers, and packaging machinery. A Teflon bearing eliminates the risk of lubricant contamination, a critical safety requirement.

Electrical Insulation

Teflon is an outstanding electrical insulator. This property is crucial in applications where the bearing must prevent the flow of electricity.

This makes it a key component in the electronics and semiconductor industries, where it is used in manufacturing equipment to isolate sensitive components from stray electrical currents.

Understanding the Trade-offs

While its properties are exceptional, Teflon is not a universal solution. An objective assessment requires understanding its limitations.

Lower Mechanical Strength

Compared to steel or bronze, pure Teflon is a relatively soft material. Under very high static loads, it can be susceptible to "creep," or slow deformation over time.

For this reason, high-load applications often use composite Teflon bearings, which are reinforced with fillers like glass fiber, carbon, or bronze to improve strength and rigidity.

Abrasion and Wear Resistance

While its low friction is a major benefit, pure Teflon can wear more quickly than hard metals in highly abrasive environments or high-speed applications.

Again, this limitation is often overcome by creating composites. Fillers are blended into the Teflon to significantly enhance its durability and wear resistance for more demanding mechanical roles.

Making the Right Choice for Your Application

Selecting the right bearing material requires aligning its properties with your primary operational goal.

- If your primary focus is preventing contamination or corrosion: Teflon's chemical inertness makes it the default choice for medical, chemical, and food-grade applications.

- If your primary focus is smooth, maintenance-free motion: The self-lubricating, low-friction nature of Teflon is ideal for machinery where access is difficult or lubrication is forbidden.

- If your primary focus is performance in extreme temperatures: Teflon's thermal stability ensures reliable operation in both high-heat and cryogenic environments where metals would fail.

- If your primary focus is supporting extreme mechanical loads: Pure Teflon may not be suitable, but a carbon or bronze-filled Teflon composite often provides the necessary strength.

Ultimately, understanding these core properties empowers you to select a material that solves your specific engineering challenge reliably and safely.

Summary Table:

| Industry | Primary Benefit of Teflon Bearings |

|---|---|

| Chemical Processing | Unmatched chemical inertness and corrosion resistance |

| Food & Beverage | Purity, non-toxicity, and prevention of contamination |

| Medical & Pharmaceutical | Chemical resistance and compliance with safety standards |

| Automotive & Heavy Machinery | Self-lubrication for maintenance-free operation |

| Aerospace | Extreme temperature stability and reliability |

| Marine | Corrosion resistance in harsh, wet environments |

| Electronics & Semiconductor | Excellent electrical insulation properties |

Need a high-performance PTFE component for your application?

KINTEK specializes in manufacturing precision PTFE components, including custom bearings, seals, and liners. We serve the semiconductor, medical, laboratory, industrial, and other specialized industries. Whether you need a prototype or a high-volume production run, our expertise ensures a solution that meets your exact requirements for chemical resistance, temperature stability, and purity.

Contact our engineering team today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability