At its core, a PTFE heat press sheet is an indispensable tool in any industry involving textile customization and printing. Its primary applications are in sublimation, heat transfer vinyl (HTV) projects, and custom apparel manufacturing where a protective, non-stick barrier is required during heat application.

While its use spans several niches, the fundamental purpose of a PTFE sheet is always the same: to protect both the product and the equipment by leveraging the material's exceptional heat resistance and non-stick properties.

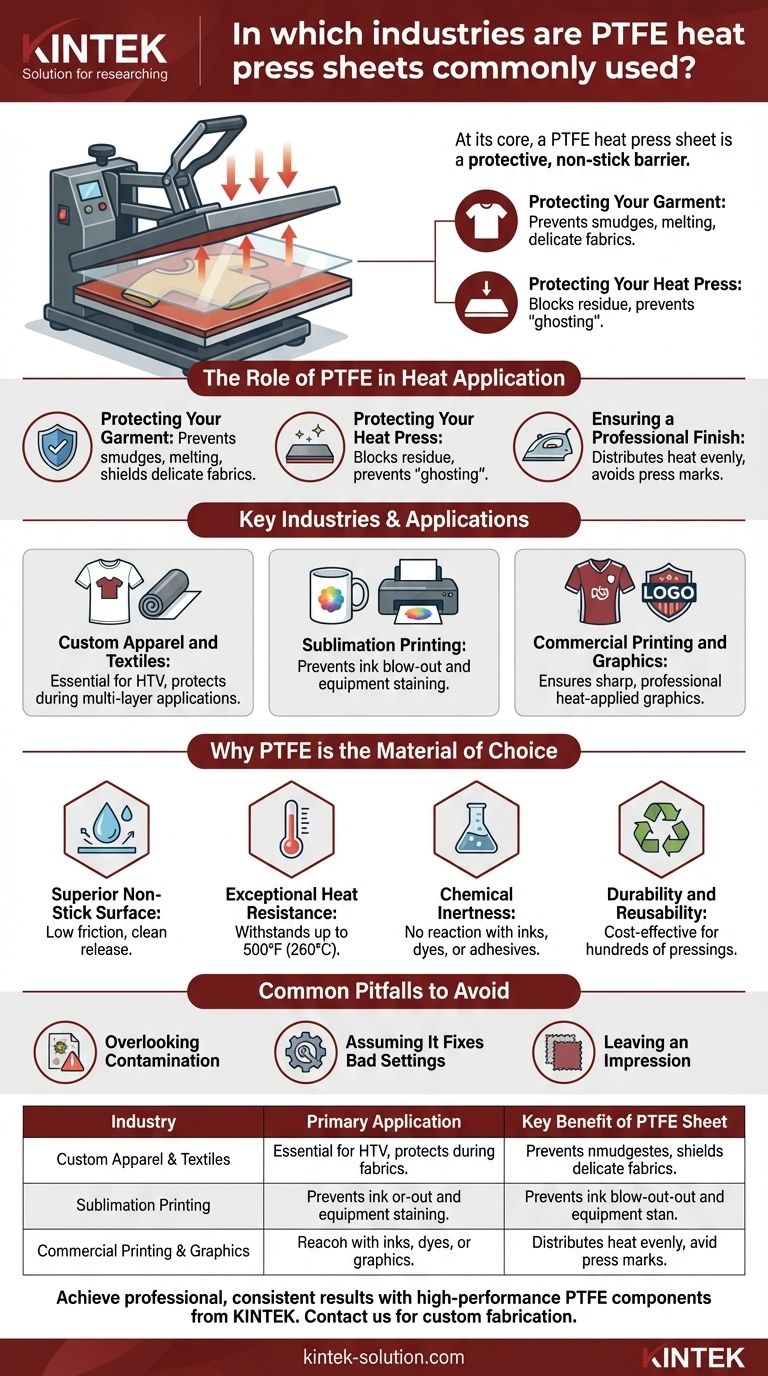

The Role of PTFE in Heat Application

Before listing the specific industries, it's crucial to understand what a PTFE sheet—often known by the brand name Teflon—actually does. It serves as a reusable, protective barrier between the hot upper platen of a heat press and the garment or transfer material below.

Protecting Your Garment

The sheet's non-stick surface prevents inks, adhesives, and vinyl from sticking to the heat press. This is critical for preventing smudges or melting, and it also shields delicate fabrics from scorching under direct, intense heat.

Protecting Your Heat Press

By blocking residue from inks and glues, the PTFE sheet keeps the heat platen clean. A clean platen is essential for preventing "ghosting," where colors or parts of an old design are accidentally transferred to a new project.

Ensuring a Professional Finish

The sheet helps distribute heat and pressure more evenly across the surface of the transfer. This leads to a more consistent, durable application without press marks or shiny spots on the fabric.

Key Industries and Their Applications

The versatility of PTFE sheets comes from the material's core properties. While the material itself is used in industries from aerospace to medical, its sheet form for heat pressing is concentrated in specific creative and manufacturing sectors.

Custom Apparel and Textiles

This is the most common application. Businesses that create custom t-shirts, hoodies, tote bags, and other textiles rely heavily on these sheets for applying heat transfer vinyl (HTV). The sheet protects the vinyl and the fabric, especially during multi-layer applications.

Sublimation Printing

In sublimation, special ink is turned into a gas that bonds with polyester fibers. A PTFE sheet is critical here to prevent the ink from "blowing out" beyond the design's edges and to stop the gaseous dye from staining the heat press.

Commercial Printing and Graphics

Any business that produces heat-applied graphics, such as custom logos on team jerseys or branding on promotional items, uses PTFE sheets. They ensure every press is clean, sharp, and professional.

Why PTFE is the Material of Choice

The reason PTFE dominates these industries is its unique combination of powerful physical properties.

Superior Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid. In simple terms, almost nothing sticks to it, making it the perfect material for clean release after pressing.

Exceptional Heat Resistance

The material can easily withstand the typical temperatures used in heat pressing (up to 500°F or 260°C) without degrading, melting, or releasing harmful fumes.

Chemical Inertness

PTFE does not react with the inks, dyes, or adhesives used in textile printing. This guarantees that the material won't alter the color or chemical composition of the transfer.

Durability and Reusability

A single PTFE sheet can be used for hundreds, if not thousands, of pressings. This makes it an incredibly cost-effective tool for both small hobbyists and large-scale commercial operations.

Common Pitfalls to Avoid

While highly effective, a PTFE sheet is a tool that must be used correctly to achieve the best results.

Overlooking Contamination

The non-stick surface is excellent, but it isn't self-cleaning. If a small piece of vinyl or ink residue is left on the sheet, it will be transferred to the next garment. Always wipe the sheet clean between uses.

Assuming It Fixes Bad Settings

A PTFE sheet cannot compensate for incorrect temperature, pressure, or time settings on your heat press. It protects the materials but does not fix an improper application process.

Leaving an Impression

On certain sensitive fabrics, the edge of the sheet can leave a faint impression if the pressure is too high. Using a sheet that is significantly larger than your design can help mitigate this.

How to Apply This to Your Project

Your choice to use a PTFE sheet should be based on the materials and process you are working with.

- If your primary focus is applying standard heat transfer vinyl (HTV): A PTFE sheet is a non-negotiable tool for protecting your garment and press platen from residue.

- If your primary focus is sublimation printing: You must use a protective sheet to prevent ink from permanently staining your equipment.

- If your primary focus is creating multi-layer or complex designs: The sheet is essential for protecting the underlying, already-applied layers of vinyl as you add new ones.

Ultimately, incorporating a PTFE heat press sheet into your workflow is a fundamental step toward achieving consistent, professional-quality results.

Summary Table:

| Industry | Primary Application | Key Benefit of PTFE Sheet |

|---|---|---|

| Custom Apparel & Textiles | Applying Heat Transfer Vinyl (HTV) | Protects fabric and press from residue, ensures clean release |

| Sublimation Printing | Transferring dye-sublimation inks | Prevents ink blow-out and equipment staining |

| Commercial Printing & Graphics | Producing heat-applied logos and branding | Guarantees sharp, professional finishes on promotional items |

Achieve professional, consistent results in your textile projects with high-performance PTFE components from KINTEK.

Whether you're in custom apparel manufacturing, sublimation printing, or commercial graphics, our precision-manufactured PTFE heat press sheets provide the durable, non-stick barrier you need to protect both your products and equipment. We specialize in custom fabrication from prototypes to high-volume orders, ensuring you get the exact specifications for your industry's demands.

Ready to enhance your heat application process? Contact our experts today to discuss your specific needs and discover how KINTEK's PTFE solutions can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application