In short, PTFE expansion joints are indispensable in any industry that handles aggressive chemicals, operates at extreme temperatures, or requires absolute product purity. They are most commonly found in chemical processing, power generation, pharmaceutical manufacturing, and food and beverage production.

The widespread use of PTFE expansion joints is not accidental. It is a direct result of PTFE's unique molecular structure, which provides a combination of chemical inertness, temperature resistance, and flexibility that few other materials can match for protecting critical piping systems.

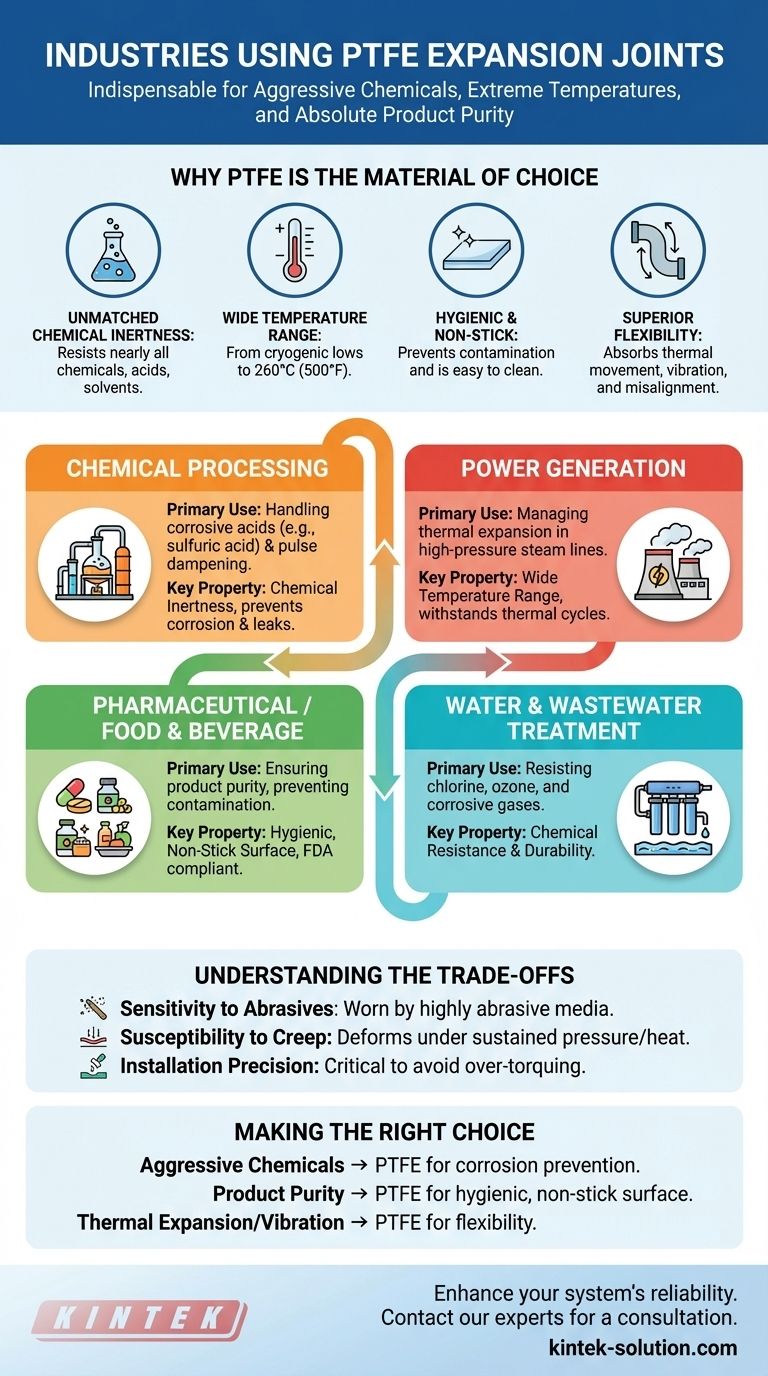

Why PTFE is the Material of Choice

The decision to use a PTFE expansion joint is driven by the need to protect expensive and sensitive piping systems from stress, vibration, and corrosion. PTFE (Polytetrafluoroethylene) possesses a unique set of properties that makes it ideal for these demanding environments.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and solvents. This chemical inertness is its most significant advantage.

This property makes it the default material for pipelines in chemical and petrochemical plants, where it prevents corrosion, leaks, and an eventual loss of containment.

Wide Operational Temperature Range

PTFE expansion joints can function effectively in a broad temperature spectrum, from cryogenic lows to high-heat applications up to 260°C (500°F).

This makes them critical components in power generation facilities for handling high-pressure steam and managing the thermal expansion and contraction of pipes.

Hygienic and Non-Stick Surface

The surface of PTFE is extremely smooth and non-porous, which prevents materials from sticking to it. This is known as a low coefficient of friction.

This characteristic is vital for the pharmaceutical and food and beverage industries, where preventing contamination and ensuring product purity is a non-negotiable regulatory requirement.

Superior Flexibility and Vibration Absorption

As the name implies, an expansion joint must be flexible. PTFE excels at absorbing thermal movement, pipe misalignment, and system vibration.

This protects rotating equipment like pumps and turbines from the stresses of the attached piping system and is valuable in complex networks found in pollution control and HVAC systems.

Key Industry Applications in Detail

While many industries use PTFE, four stand out as the primary adopters due to the severity of their operating conditions.

Chemical Processing

In chemical plants, PTFE expansion joints are used to handle highly corrosive substances like sulfuric acid, chlorine, and caustic soda. They are the frontline defense against leaks and joint failure.

They also function as pulse dampeners in lines with high-pressure fluctuations, protecting sensitive instruments and downstream equipment.

Pharmaceutical and Food & Beverage

In these industries, the primary goal is preventing contamination. PTFE's inert and non-stick nature ensures that the final product remains pure.

These joints are easy to clean (Clean-in-Place) and comply with stringent hygiene and safety standards, such as those from the FDA.

Power Generation

Power plants operate with extreme temperature and pressure differentials. PTFE expansion joints safely absorb the constant thermal expansion and contraction of steam and coolant lines.

Their ability to withstand these cycles reduces mechanical stress on the entire piping infrastructure, preventing premature failure.

Water and Wastewater Treatment

Water treatment facilities use a variety of chemicals like chlorine and ozone to purify water. PTFE easily withstands these chemicals over long periods.

In wastewater, these joints can handle the abrasive nature of certain slurries and the corrosive gases generated during treatment processes.

Understanding the Trade-offs

Despite its advantages, PTFE is not a universal solution. Understanding its limitations is key to proper application.

Sensitivity to Abrasives

While effective for some slurries, PTFE can be worn down by highly abrasive media. In such cases, an elastomer-lined joint might be a more durable choice.

Susceptibility to Creep

Under sustained pressure and high temperatures, PTFE can slowly deform over time, a phenomenon known as creep. This must be accounted for in the system's design to ensure a long service life.

Installation Precision

The performance of a PTFE expansion joint is highly dependent on correct installation. Over-torquing the flange bolts is a common error that can crush the PTFE and lead to a premature sealing failure.

Making the Right Choice for Your Goal

Selecting the correct expansion joint requires matching the material properties to your system's primary challenge.

- If your primary focus is handling aggressive chemicals: PTFE is the gold standard for preventing corrosion and ensuring the long-term integrity of your piping.

- If your primary focus is product purity and hygiene: PTFE's inert, non-stick surface is essential for meeting the strict regulatory demands of pharmaceutical and food-grade applications.

- If your primary focus is managing thermal expansion and vibration: PTFE expansion joints offer excellent flexibility and durability in high-temperature or dynamic systems like power plants and HVAC.

Ultimately, choosing a PTFE expansion joint is an investment in your system's reliability, safety, and operational longevity.

Summary Table:

| Industry | Primary Use Case | Key PTFE Property Utilized |

|---|---|---|

| Chemical Processing | Handling corrosive acids & solvents | Unmatched Chemical Inertness |

| Power Generation | Managing thermal expansion in steam lines | Wide Temperature Range (-200°C to 260°C) |

| Pharmaceutical / Food & Beverage | Ensuring product purity and preventing contamination | Hygienic, Non-Stick Surface |

| Water & Wastewater Treatment | Resisting chemicals like chlorine and ozone | Chemical Resistance & Durability |

Need a reliable PTFE expansion joint for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom expansion joints, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a solution perfectly matched to your system's demands for chemical resistance, temperature stability, and hygiene.

Enhance your system's reliability and safety. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability