At its core, a PTFE envelope gasket is specified in industries where chemical resistance and product purity are paramount. It sees widespread use in chemical processing, pharmaceuticals, food and beverage, petrochemical, semiconductor manufacturing, and power generation due to its unique combination of an inert sealing surface and a resilient core.

The fundamental value of a PTFE envelope gasket lies in its composite design. It combines the near-universal chemical inertness of a thin PTFE "envelope" with the mechanical strength and resilience of a separate core material, offering a best-of-both-worlds sealing solution for demanding applications.

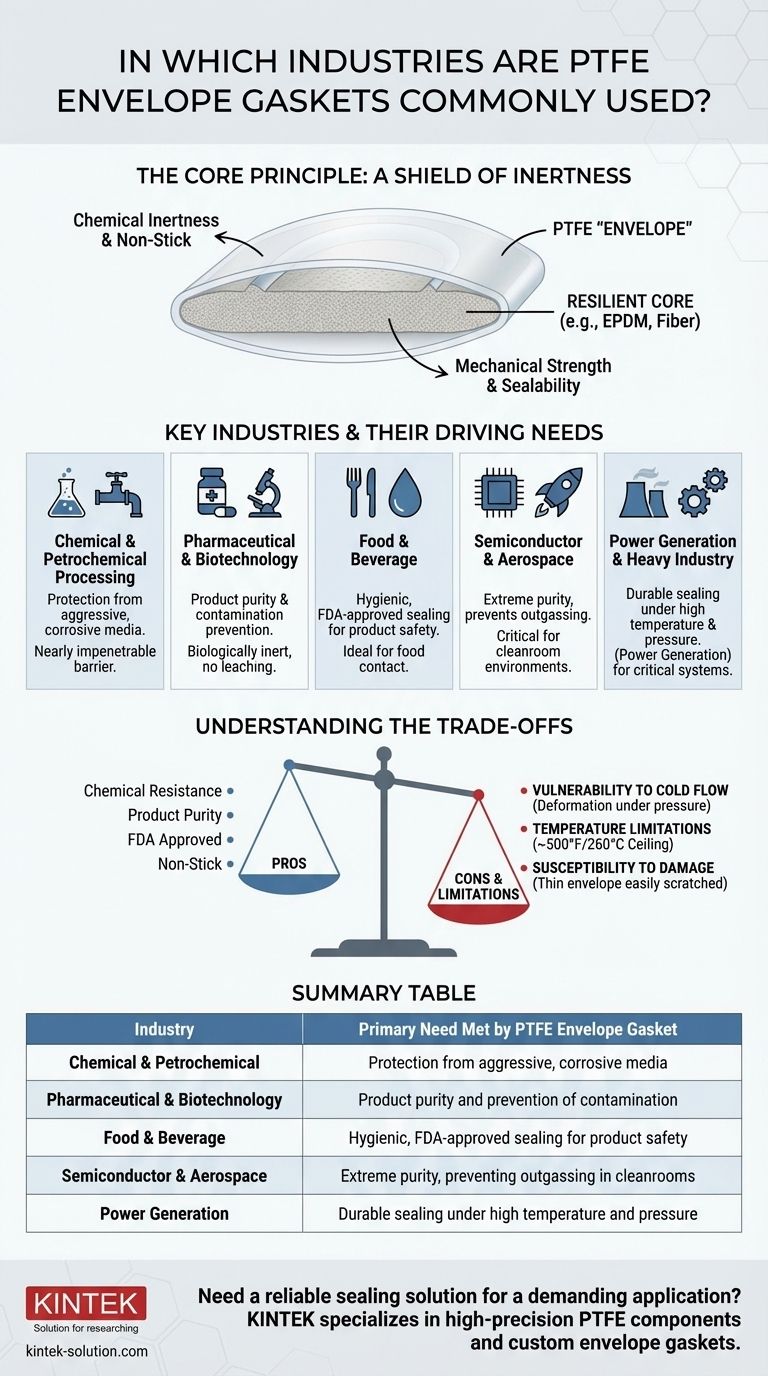

The Core Principle: A Shield of Inertness

A PTFE envelope gasket is not a solid piece of PTFE. It is a composite gasket.

It consists of a softer, more compressible core material (like non-asbestos fiber or EPDM rubber) that is wrapped in a thin, protective layer—the "envelope"—of pure PTFE.

This design cleverly solves a common engineering problem. It provides the exceptional chemical resistance and non-stick properties of PTFE on all contact surfaces, while the inner core provides the mechanical strength and compressibility needed to create a tight, durable seal.

Key Industries and Their Driving Needs

The adoption of these gaskets is not arbitrary; each industry leverages a specific property to solve a critical operational challenge.

Chemical and Petrochemical Processing

These industries handle some of the most aggressive and corrosive media, from strong acids to volatile solvents.

A PTFE envelope provides a nearly impenetrable barrier, protecting the flange surfaces and the core gasket material from chemical attack, which prevents leaks and equipment failure.

Pharmaceutical and Biotechnology

In these fields, preventing contamination is the absolute priority. The process medium must remain pure and sterile.

PTFE is biologically inert and does not leach contaminants, ensuring that the final product, whether a medication or a bioprocessed compound, maintains its required purity.

Food and Beverage

Similar to pharmaceuticals, the food and beverage industry requires hygienic conditions to prevent contamination and ensure consumer safety.

PTFE is FDA-approved for food contact applications, making it an ideal choice for sealing piping, tanks, and processing equipment where it will touch the product.

Semiconductor and Aerospace

These high-technology sectors demand extreme purity and reliability. In semiconductor manufacturing, even microscopic contamination can ruin a batch of microchips.

The non-reactive and high-purity nature of the PTFE surface prevents outgassing or particulate shedding, which is critical for cleanroom environments and sensitive aerospace components.

Power Generation and Heavy Industry

Applications in power plants and pulp and paper mills involve high temperatures, high pressures, and often harsh chemical treatments.

PTFE envelope gaskets provide a stable and durable seal that can withstand these conditions, ensuring operational reliability in critical systems like pipelines, valves, and pressure vessels.

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are not a universal solution. Understanding their limitations is key to proper application.

Vulnerability to Cold Flow

PTFE's primary weakness is its tendency to "creep" or "cold flow"—a slow deformation under sustained pressure and temperature.

While the gasket's inner core provides resistance, improper torque or extreme conditions can cause the seal to loosen over time. Regular bolt torque checks may be necessary in critical applications.

Temperature Limitations

The operational temperature range is defined by both the PTFE envelope and the core material.

While excellent for many processes, PTFE has a definitive ceiling (around 500°F / 260°C) and can become brittle at cryogenic temperatures. It cannot replace metallic gaskets in extremely high-temperature services.

Susceptibility to Damage

The thin PTFE envelope is relatively soft and can be easily scratched or damaged during installation, especially on rough or serrated flange surfaces.

They perform best on smooth, clean flange faces, such as those found on glass-lined steel, plastic, or other delicate equipment where aggressive gasket types would cause damage.

Making the Right Choice for Your Goal

Selecting the right gasket depends entirely on the primary demand of your application.

- If your primary focus is product purity: A PTFE envelope gasket is the industry standard for pharmaceutical, food, and semiconductor applications to prevent contamination.

- If your primary focus is aggressive chemical resistance: This gasket excels at protecting equipment from corrosion in chemical and petrochemical plants.

- If your primary focus is sealing delicate flanges: The soft PTFE surface is ideal for creating a seal on glass-lined, ceramic, or plastic flanges without causing damage.

Ultimately, choosing a PTFE envelope gasket is a strategic decision to shield a critical process from contamination or corrosion.

Summary Table:

| Industry | Primary Need Met by PTFE Envelope Gasket |

|---|---|

| Chemical & Petrochemical | Protection from aggressive, corrosive media |

| Pharmaceutical & Biotechnology | Product purity and prevention of contamination |

| Food & Beverage | Hygienic, FDA-approved sealing for product safety |

| Semiconductor & Aerospace | Extreme purity, preventing outgassing in cleanrooms |

| Power Generation | Durable sealing under high temperature and pressure |

Need a reliable sealing solution for a demanding application?

KINTEK specializes in manufacturing high-precision PTFE components, including custom envelope gaskets. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures a perfect seal that protects your process from contamination and corrosion.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications