In short, mechanical seals with Polytetrafluoroethylene (PTFE) rings are indispensable in industries that handle aggressive chemicals, require absolute purity, or operate in extreme temperatures. They are most prominently used in the chemical and petrochemical, food and pharmaceutical, and aerospace sectors, but their unique properties also lead to applications in construction, medical, and even household appliances.

The core reason for PTFE's widespread use is its unique combination of near-universal chemical inertness and a very wide operational temperature range. This makes it a problem-solver for sealing applications where conventional elastomers or plastics would quickly degrade and fail.

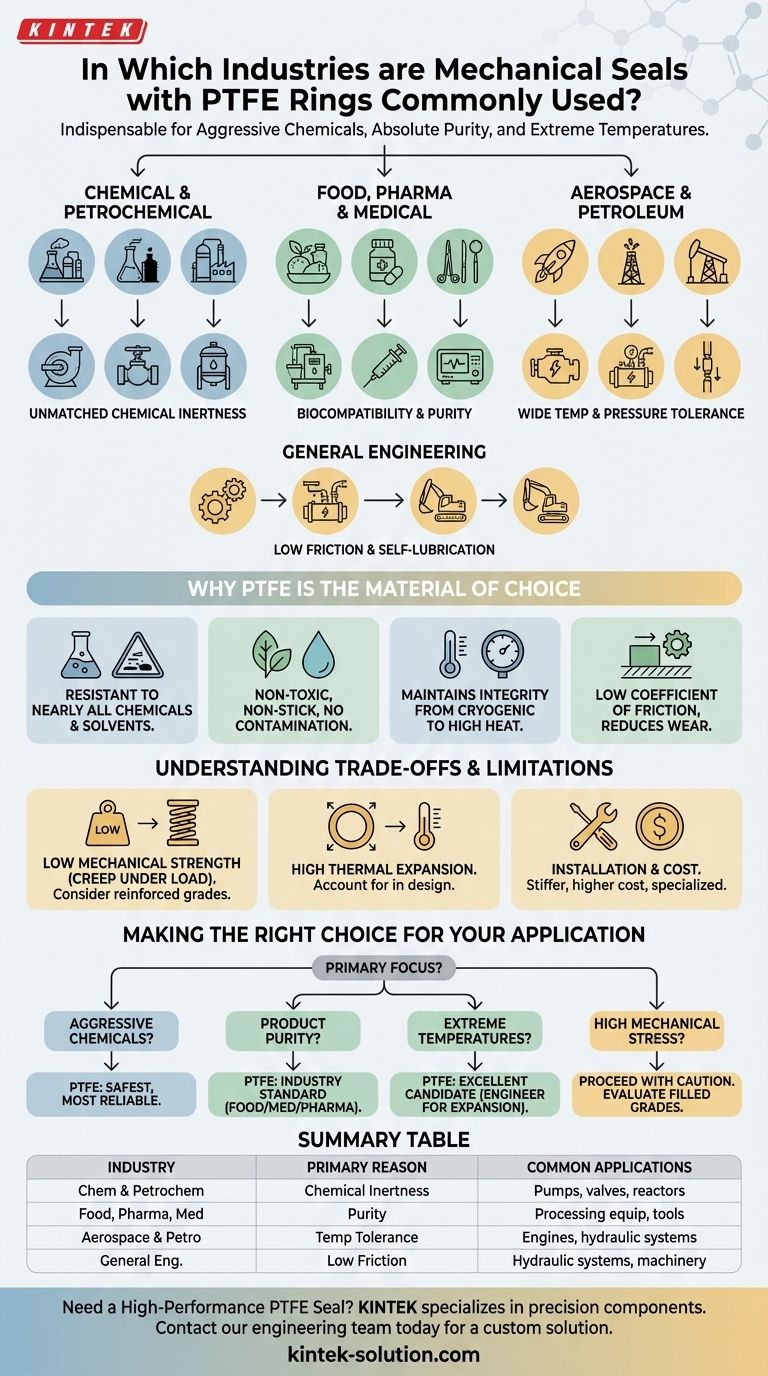

Why PTFE is the Material of Choice

The selection of a seal material is driven by the demands of the operating environment. PTFE excels where conditions are most challenging, making it a critical component in high-stakes industries.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This property is non-negotiable in certain applications.

This makes it the primary choice for pumps, valves, and reactors in the chemical and petrochemical industries, where seals are constantly exposed to corrosive and aggressive media.

Biocompatibility and Purity

PTFE is non-toxic, non-stick, and does not contaminate the media it contacts. This ensures the integrity of the end product.

For this reason, it is heavily relied upon in the food, pharmaceutical, and medical industries for applications like processing equipment, surgical tools, and analytical devices where purity is paramount.

Wide Temperature and Pressure Tolerance

PTFE seals maintain their integrity and performance across a broad spectrum of temperatures, from cryogenic levels to high heat.

This resilience is vital in the aerospace and petroleum industries, where seals are used in engines, hydraulic systems, and downhole drilling tools that experience extreme temperature fluctuations and high-pressure (HPHT) environments.

Low Friction and Self-Lubrication

PTFE has an exceptionally low coefficient of friction, which reduces wear on moving parts and improves energy efficiency.

This property is valuable across general mechanical engineering and in heavy-duty applications like the hydraulic systems of construction machinery, where it extends the life of the seal and associated components.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. Its mechanical properties introduce specific trade-offs that must be considered during the design and selection process.

Low Mechanical Strength

Pure PTFE can deform or "creep" under high compressive loads, especially at elevated temperatures. This can compromise the effectiveness of the seal over time.

This makes it less suitable for applications with very high dynamic loads unless it is reinforced with fillers like glass, carbon, or graphite.

High Coefficient of Thermal Expansion

PTFE expands and contracts with temperature changes more significantly than most metals.

This behavior must be accounted for in the system's design to ensure the seal maintains proper contact and pressure across its entire operating temperature range.

Installation and Cost

PTFE rings can be stiffer and more challenging to install than flexible elastomer seals, with a higher risk of damage if not handled correctly.

Additionally, PTFE is generally a more expensive material compared to standard rubber or plastic sealing options, reflecting its specialized manufacturing and performance characteristics.

Making the Right Choice for Your Application

Selecting a PTFE seal requires balancing its exceptional benefits against its specific limitations. Your primary goal will determine if it's the right fit.

- If your primary focus is handling aggressive chemicals: PTFE is often the safest and most reliable choice due to its near-universal chemical resistance.

- If your primary focus is product purity: The inert, non-stick, and biocompatible nature of PTFE makes it an industry standard for food, medical, and pharmaceutical applications.

- If your primary focus is extreme temperatures: PTFE is an excellent candidate, but you must engineer the system to accommodate its high thermal expansion.

- If your primary focus is high mechanical stress: Proceed with caution; evaluate filled PTFE grades or alternative materials better suited for high dynamic loads.

Ultimately, understanding both the strengths and weaknesses of PTFE empowers you to select a sealing solution that ensures safety, reliability, and performance.

Summary Table:

| Industry | Primary Reason for PTFE Use | Common Applications |

|---|---|---|

| Chemical & Petrochemical | Unmatched chemical inertness | Pumps, valves, reactors |

| Food, Pharma & Medical | Biocompatibility and purity | Processing equipment, surgical tools |

| Aerospace & Petroleum | Extreme temperature tolerance | Engines, hydraulic systems, HPHT tools |

| General Engineering | Low friction and self-lubrication | Hydraulic systems, construction machinery |

Need a High-Performance PTFE Seal for Your Application?

KINTEK specializes in manufacturing precision PTFE components, including mechanical seals, liners, and custom labware. We serve demanding industries like semiconductor, medical, and chemical processing, where material performance is critical.

We provide:

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Expertise: Ensuring your seals meet the specific chemical, thermal, and mechanical demands of your application.

- Precision Production: Guaranteeing reliability and longevity in even the harshest environments.

Contact our engineering team today to discuss your sealing requirements and get a custom solution that ensures safety, reliability, and peak performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments