At its core, Polytetrafluoroethylene (PTFE) is the material of choice for valve seats in applications defined by two key challenges: aggressive chemical media and high operating temperatures. Its unique molecular structure makes it virtually inert to most chemicals and stable across a wide thermal range, positioning it as a problem-solver in industries like chemical processing, oil and gas, and pharmaceutical manufacturing where lesser materials would quickly fail.

The decision to use a PTFE valve seat is fundamentally a decision for chemical and thermal resilience. It excels where other materials degrade, offering unparalleled reliability in harsh service conditions, though this specialization comes with specific mechanical trade-offs.

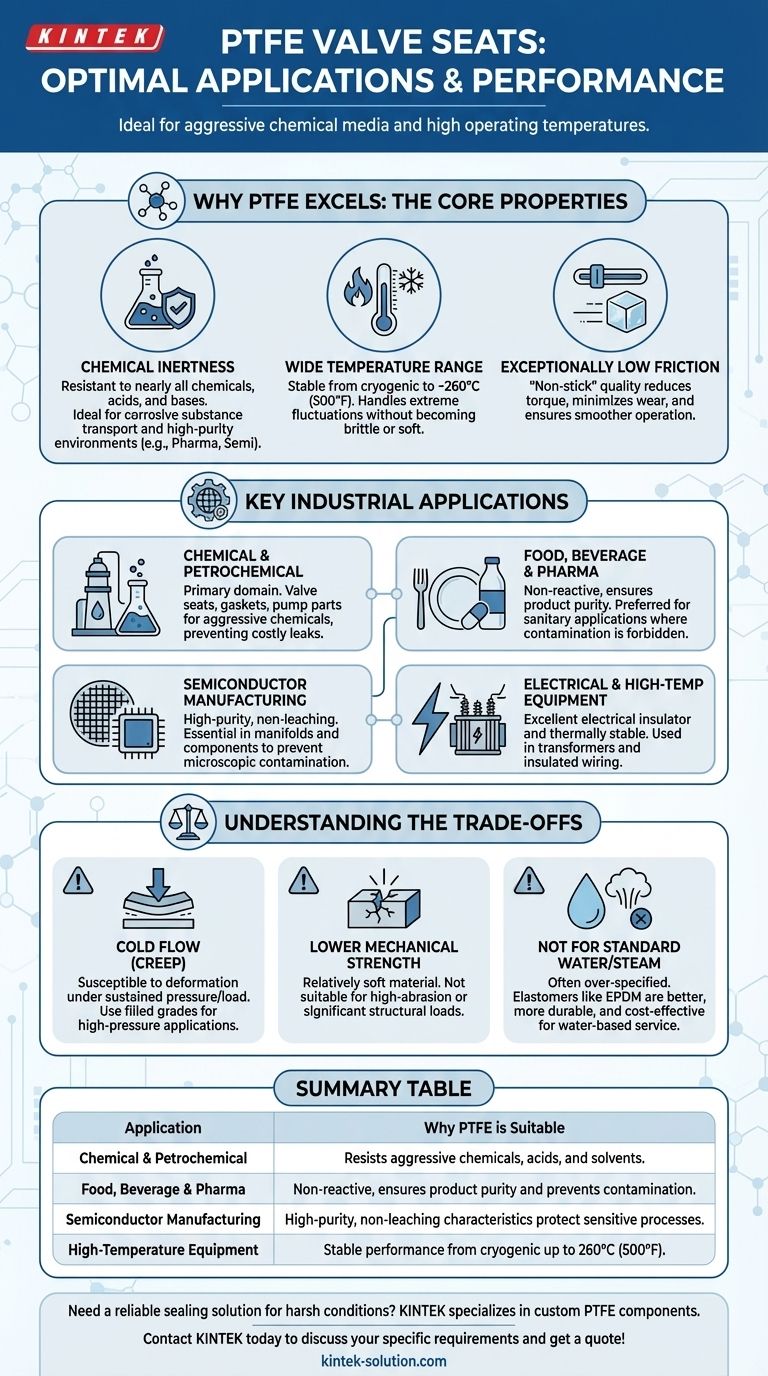

Why PTFE Excels: The Core Properties

The suitability of PTFE is not arbitrary; it stems directly from a unique combination of material characteristics. Understanding these properties is crucial to deploying it effectively.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and bases. This makes it an ideal sealing material in systems that transport or process corrosive substances.

Its inertness ensures that the valve seat will not degrade, swell, or contaminate the process media, which is critical in high-purity applications like semiconductor or pharmaceutical production.

Wide Operating Temperature Range

PTFE maintains its integrity and sealing capability across an exceptionally broad temperature spectrum, from cryogenic conditions up to approximately 260°C (500°F).

This thermal stability allows it to be used in high-temperature processes or in equipment that experiences significant temperature fluctuations without becoming brittle or soft.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This "non-stick" quality is highly beneficial in valve applications. It reduces the torque required to open or close the valve, minimizing wear on moving parts and ensuring smoother, more reliable operation over the valve's lifespan.

Key Industrial Applications

These core properties translate directly into superior performance in several demanding industrial sectors.

Chemical and Petrochemical Processing

This is the primary domain for PTFE. It is used extensively in valve seats, gaskets, pump parts, and vessel linings that handle aggressive chemicals, solvents, and acids. Its reliability prevents costly leaks and shutdowns.

Food, Beverage, and Pharmaceutical

Due to its inertness, PTFE does not react with or contaminate the product. This makes it a preferred material for sanitary applications in food processing, beverage manufacturing, and medical devices where purity is non-negotiable.

High-Purity and Semiconductor Manufacturing

In environments where even microscopic contamination can ruin a product batch, PTFE's purity and non-leaching characteristics are essential. It's found in manifolds, tubing, and valve components for this reason.

Electrical and High-Temperature Equipment

PTFE is an excellent electrical insulator and retains this property at high temperatures. This makes it suitable for components in transformers, insulated wiring, and other electrical applications exposed to heat.

Understanding the Trade-offs: When to Reconsider PTFE

No material is perfect. Acknowledging PTFE's limitations is key to avoiding misapplication and ensuring system integrity.

Susceptibility to Cold Flow (Creep)

Under sustained pressure and load, especially at elevated temperatures, PTFE can slowly deform or "creep." This can compromise seal integrity over time in very high-pressure applications.

For these situations, "filled" grades of PTFE (mixed with glass, carbon, or other materials) are often used to enhance creep resistance and mechanical strength.

Lower Mechanical Strength

Compared to metals or other engineering plastics, PTFE is a relatively soft material. It is not suitable for high-abrasion applications or as a structural component bearing a significant mechanical load.

Not Ideal for Standard Water and Steam

While PTFE can handle water and steam, it is often an over-specified and less cost-effective choice compared to elastomers. Materials like EPDM are specifically designed for water-based applications and often provide a better, more durable seal in those conditions.

Selecting the Right Seat for Your Application

Your final choice should be dictated by the specific demands of your system.

- If your primary focus is handling aggressive chemicals or high temperatures: PTFE is almost certainly your best and most reliable option.

- If your primary focus is high-pressure sealing without extreme chemicals: Consider a filled PTFE grade or an alternative polymer to mitigate the risk of cold flow.

- If your primary focus is standard water, air, or steam service: An elastomer like EPDM will likely provide a more durable and cost-effective solution.

Understanding these core properties and trade-offs is the key to leveraging PTFE's unique strengths for maximum system reliability.

Summary Table:

| Application | Why PTFE is Suitable |

|---|---|

| Chemical & Petrochemical | Resists aggressive chemicals, acids, and solvents. |

| Food, Beverage & Pharma | Non-reactive, ensures product purity and prevents contamination. |

| Semiconductor Manufacturing | High-purity, non-leaching characteristics protect sensitive processes. |

| High-Temperature Equipment | Stable performance from cryogenic up to 260°C (500°F). |

Need a reliable sealing solution for harsh conditions? KINTEK specializes in manufacturing high-performance, custom PTFE components—including valve seats, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a component that perfectly matches your application's demands for chemical resistance and thermal stability.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications