In short, PTFE seals are the standard choice for high-temperature applications across the petroleum, aerospace, chemical processing, and industrial manufacturing sectors. They are specified wherever machinery must operate reliably in environments that combine high heat with other demanding factors like corrosive chemicals, high pressure, or high rotational speeds.

The core reason for PTFE's widespread use isn't just its ability to withstand heat. It's the material's unique combination of thermal stability, extreme chemical inertness, and low friction, which allows it to solve complex sealing challenges where most other materials would quickly fail.

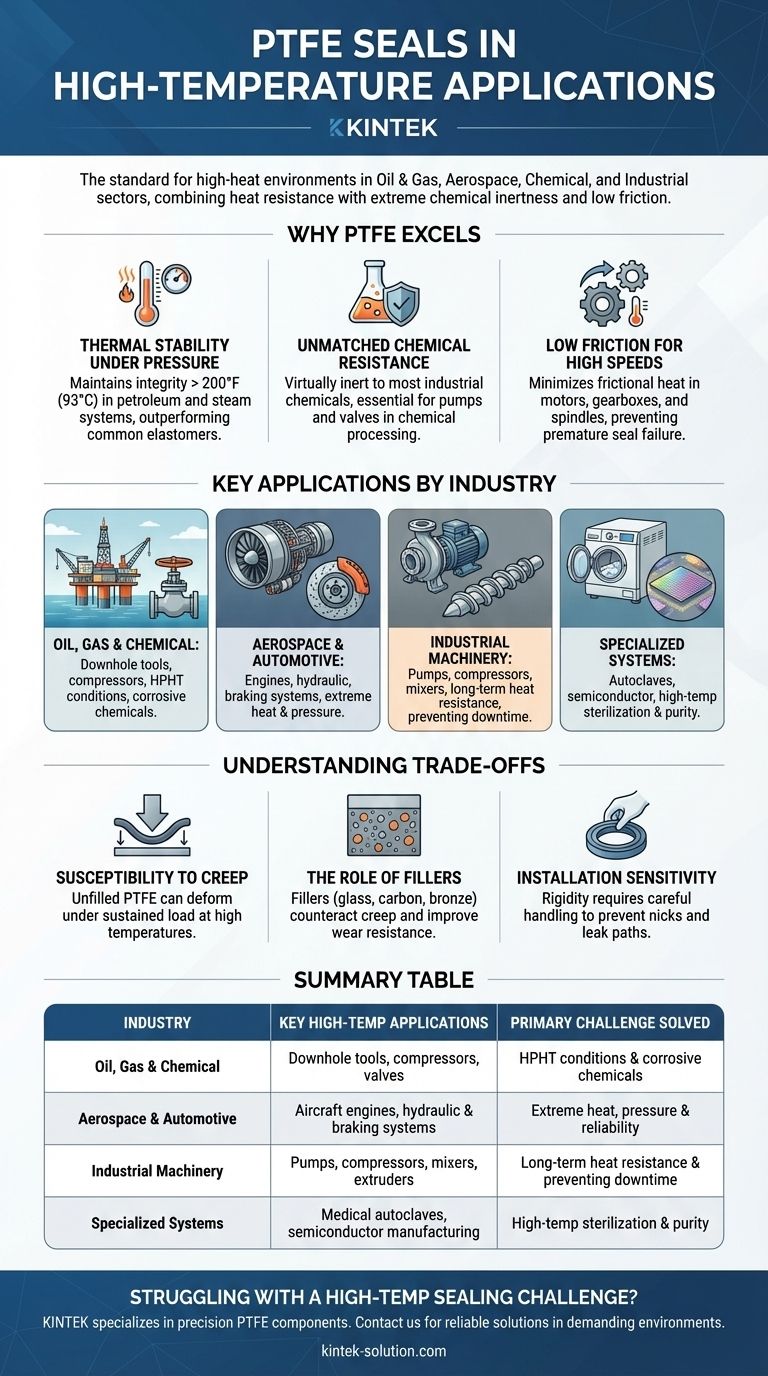

Why PTFE Excels in Demanding Environments

Understanding the properties of Polytetrafluoroethylene (PTFE) is key to recognizing why it's so frequently specified for difficult sealing jobs. The decision to use PTFE is rarely based on temperature alone.

Thermal Stability Under Pressure

PTFE maintains its structural integrity and sealing capability in applications that greatly exceed 200°F (93°C), such as in petroleum and steam systems. This allows it to function where common elastomers would degrade and fail.

Unmatched Chemical Resistance

High temperatures often accelerate chemical reactions. PTFE is virtually inert to almost all industrial chemicals, making it essential for sealing pumps, valves, and transport systems in chemical processing plants.

Low Friction for High-Speed Applications

In equipment like motors, gearboxes, and spindles, high rotational speeds generate significant frictional heat. PTFE's extremely low coefficient of friction minimizes this heat buildup, preventing premature seal failure and improving equipment efficiency.

Key High-Temperature Applications by Industry

While the principles are universal, the specific problems PTFE solves are best illustrated by looking at its use across different sectors.

Oil, Gas, and Chemical Processing

This is a primary application area for PTFE. It's used extensively in downhole tools, compressors, valves, and subsea equipment where seals must withstand High-Pressure High-Temperature (HPHT) conditions and aggressive chemicals.

Aerospace and Automotive

The need for absolute reliability makes PTFE a go-to material. It is found in aircraft engines, hydraulic systems, and braking systems where seals are exposed to high operating temperatures, pressures, and specialized fluids.

Industrial Machinery and Manufacturing

PTFE seals are critical components in a vast range of machinery, including pumps, compressors, mixers, and extruders. They provide durable, long-lasting seals in equipment that runs hot for extended periods, preventing leaks and costly downtime.

Specialized and High-Purity Systems

In medical applications like autoclaves and surgical tools, PTFE seals withstand high-temperature sterilization processes while maintaining biocompatibility. Similarly, in semiconductor manufacturing, their purity and heat resistance are vital for creating controlled environments.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Acknowledging its limitations is crucial for successful implementation.

Susceptibility to Creep

Unfilled, or "virgin," PTFE can be prone to cold flow or creep—a slow deformation under sustained load. This effect is more pronounced at higher temperatures, potentially compromising the sealing interface over time.

The Critical Role of Fillers

To counteract creep and improve wear resistance, PTFE is often blended with fillers like glass, carbon, or bronze. Choosing the correct filled PTFE compound is critical for performance in a specific high-temperature, high-pressure application.

Installation Sensitivity

Compared to flexible rubber seals, PTFE seals are often more rigid. This makes them more sensitive to nicks or scratches during installation, which can create a leak path. Proper handling and installation procedures are non-negotiable.

Making the Right Choice for Your Application

Selecting the right seal depends entirely on the primary challenge you need to solve.

- If your primary focus is sealing against extreme heat and corrosive chemicals: PTFE is the ideal choice for applications in the oil and gas or chemical processing industries.

- If your primary focus is managing friction in high-speed rotating equipment: PTFE lip seals are the superior option for motors, gearboxes, and pumps operating at high temperatures.

- If your primary focus is absolute reliability in harsh aerospace or automotive systems: PTFE seals provide the necessary performance for critical engine, hydraulic, and braking components.

- If your primary focus is maintaining purity during high-temperature processes: The inertness of PTFE makes it essential for medical sterilization and semiconductor manufacturing.

Ultimately, PTFE is the definitive engineering material for sealing applications where heat is just one of several extreme conditions that must be overcome.

Summary Table:

| Industry | Key High-Temperature Applications | Primary Challenge Solved |

|---|---|---|

| Oil, Gas & Chemical | Downhole tools, compressors, valves | HPHT conditions & corrosive chemicals |

| Aerospace & Automotive | Aircraft engines, hydraulic & braking systems | Extreme heat, pressure & reliability |

| Industrial Machinery | Pumps, compressors, mixers, extruders | Long-term heat resistance & preventing downtime |

| Specialized Systems | Medical autoclaves, semiconductor manufacturing | High-temperature sterilization & purity |

Struggling with a high-temperature sealing challenge? KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors. Whether you need a custom prototype or a high-volume order, our expertise ensures a reliable solution for your most demanding environments.

Contact KINTEK today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance