PTFE slide bearings enhance structural integrity by decoupling a structure from harmful forces. They accomplish this by supporting immense vertical loads while simultaneously allowing for nearly frictionless horizontal movement. This controlled sliding action absorbs and dissipates energy from sources like thermal expansion, seismic activity, and load deflection, preventing the build-up of destructive stress within the primary structural members.

The essential purpose of a PTFE slide bearing is to manage, not resist, movement. By providing a controlled, low-friction interface, it absorbs forces that would otherwise compromise the core components of a structure, ensuring long-term safety, durability, and performance.

The Core Principle: Managing Movement Under Load

To understand how PTFE bearings protect a structure, it's necessary to look at their fundamental design and the unique properties of Polytetrafluoroethylene (PTFE).

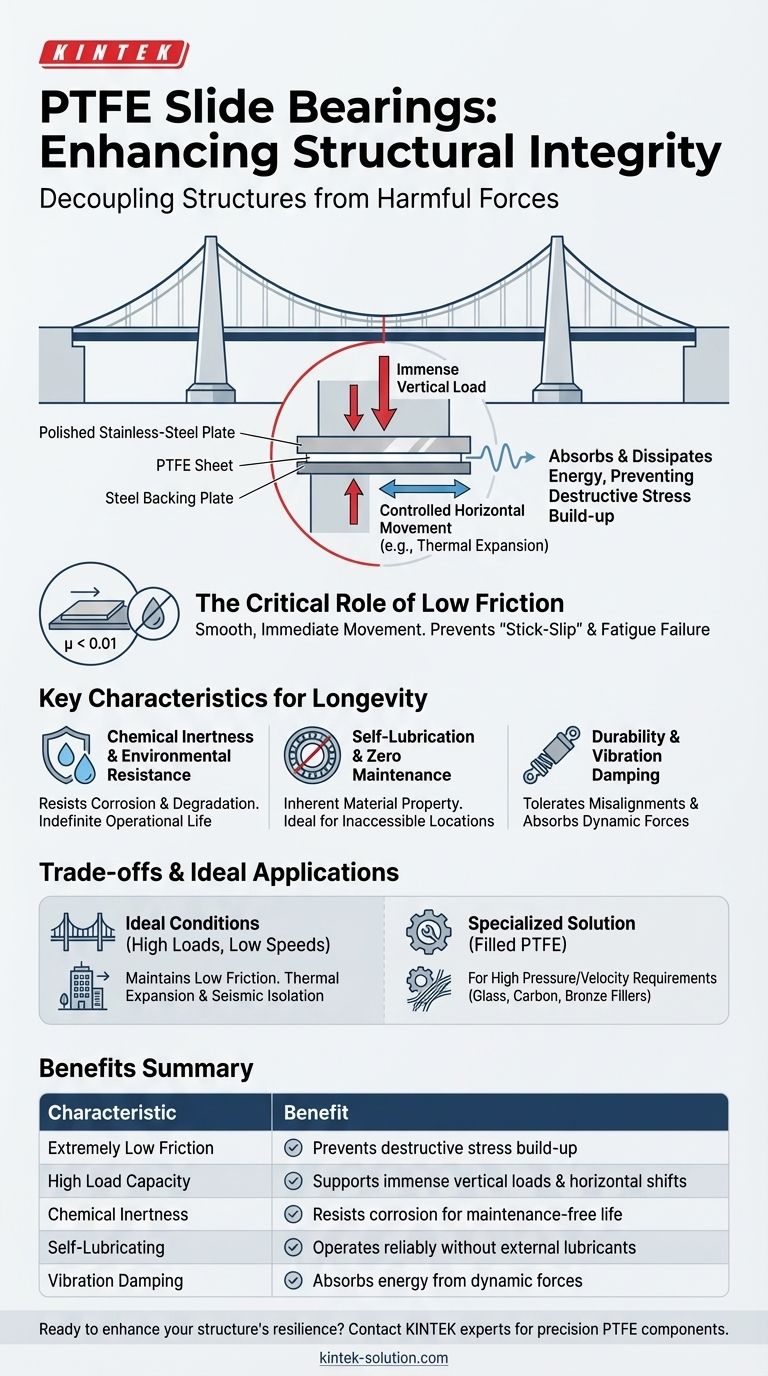

How PTFE Bearings are Constructed

A typical slide bearing consists of a PTFE sheet bonded to a steel backing plate. A polished stainless-steel plate is placed on top of the PTFE sheet and is attached to the opposing structural element.

This simple, compact assembly is designed to handle immense vertical loads while allowing the stainless-steel plate to slide smoothly across the PTFE surface.

The Critical Role of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property is central to its function in a structural bearing.

Because the friction is so low, the bearing prevents "stick-slip" behavior. Movement is smooth and immediate, ensuring that forces are dissipated as they occur rather than building up to a critical point.

Preventing Stress and Fatigue

Large structures are not static; they move constantly due to temperature changes, wind, or the weight they carry. Without a mechanism to accommodate this movement, immense stress would be transferred directly into beams, columns, and foundations.

PTFE bearings create a release valve for this stress. They allow components to expand, contract, and shift independently, preventing fatigue failure and preserving the integrity of the overall structure.

Key Characteristics That Ensure Longevity

The value of PTFE bearings extends beyond their mechanical function. Their material properties ensure they perform reliably for the entire lifespan of the structure.

Chemical Inertness and Environmental Resistance

PTFE is almost completely chemically inert and can operate across a wide temperature range. This means it will not corrode, degrade, or fail due to environmental exposure, giving it a virtually indefinite operational life.

Self-Lubrication and Zero Maintenance

The low-friction nature of PTFE is inherent to the material itself, requiring no external lubricants. This self-lubricating quality makes the bearings maintenance-free.

This is a critical advantage for components installed in inaccessible parts of a bridge or building, where regular maintenance would be impractical or impossible.

Durability and Vibration Damping

PTFE bearings are tolerant of minor misalignments that can occur during construction or over time. They also provide excellent vibration damping.

Furthermore, the material is capable of absorbing small dirt particles without compromising its sliding performance, adding to its reliability in real-world conditions.

Understanding the Trade-offs and Ideal Applications

While highly effective, PTFE slide bearings are engineered for specific conditions. Understanding their ideal operating parameters is key to leveraging their benefits.

The Importance of High Loads

PTFE performs best under high pressure. The load from the structure helps maintain a clean, polished interface between the PTFE and the stainless-steel plate, ensuring the coefficient of friction remains consistently low.

The Impact of Low Speeds

These bearings are designed for slow movements, such as the gradual expansion of a bridge deck on a hot day or the slow sway of a building. They are not intended for high-velocity, dynamic applications.

The Role of Filled PTFE

For applications with exceptionally high pressure and velocity (PV) requirements, filled PTFE can be used. Adding fillers like glass fiber, carbon, or bronze can significantly increase the material's compressive strength and wear resistance.

How to Apply This to Your Project

Specifying the correct bearing is a critical decision based on the specific forces your structure must manage.

- If your primary focus is thermal expansion: PTFE bearings are the standard for long-span structures like bridges and pipelines, where they safely accommodate movement from temperature cycles.

- If your primary focus is seismic isolation: These bearings can serve as a key component in an isolation system, helping to decouple the structure from damaging ground motion.

- If your primary focus is durability and low lifecycle cost: The maintenance-free and chemically inert nature of PTFE makes it an ideal choice for any critical connection point, especially in harsh environments or inaccessible locations.

Ultimately, incorporating PTFE slide bearings is a strategic choice to design structures that are not just strong, but resilient enough to endure a lifetime of dynamic forces.

Summary Table:

| Characteristic | Benefit for Structural Integrity |

|---|---|

| Extremely Low Friction | Allows smooth, controlled movement to prevent destructive stress build-up. |

| High Load Capacity | Supports immense vertical loads while accommodating horizontal shifts. |

| Chemical Inertness | Resists corrosion and degradation for a maintenance-free, long lifespan. |

| Self-Lubricating | Operates reliably without external lubricants, even in inaccessible locations. |

| Vibration Damping | Absorbs and dissipates energy from dynamic forces like wind or earthquakes. |

Ready to enhance your structure's resilience with precision PTFE components?

KINTEK specializes in manufacturing high-performance PTFE slide bearings, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to manage your specific structural forces, whether for thermal expansion, seismic isolation, or long-term durability.

Contact our experts today to discuss how our PTFE components can protect your project's integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials